Could we just pre-pack our columns and keep them in a deep freezer with dry ice?

Yes.

Also keep the butane storage tank in the deep freezer and just drill holes in the freezer to run our lines out through, so the tank could remain closed in the freezer in the dry ice while we do the runs?

Bad idea in case of a leaky hose connection, valve seat, fitting, etc. A chilled bath will do the same thing safer.

If we use this method, would it matter if we use 1 1/2" columns or 4" columns? I have been concerned my columns will warm up too fast once I take them out. It seems like a fatter column would chill slower and potentially be cold enough for three runs as long as we keep the storage tank in the dry ice during the runs.

Skinny columns are more efficient than larger ones, and can be insulated to stay cold.

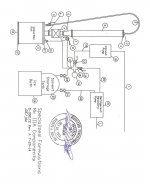

This is all relatively new to me, so I can't even fathom the Wizardry GW is speaking of with the MK VII yet.

Depending on my delusional state, sometimes I can't either.