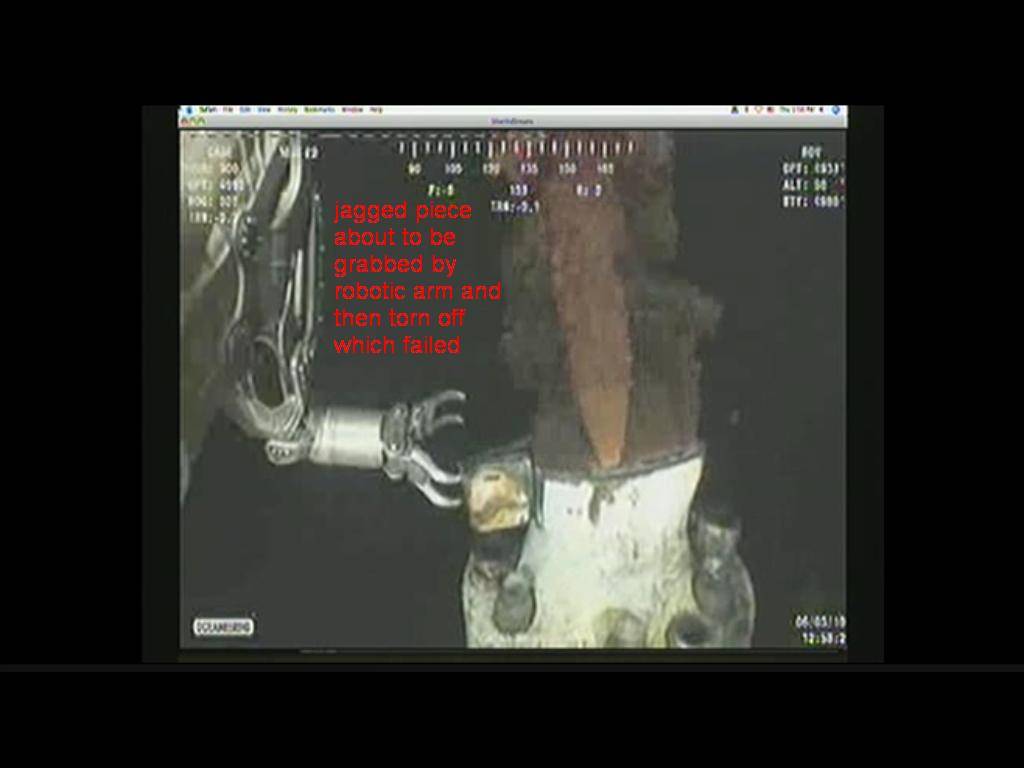

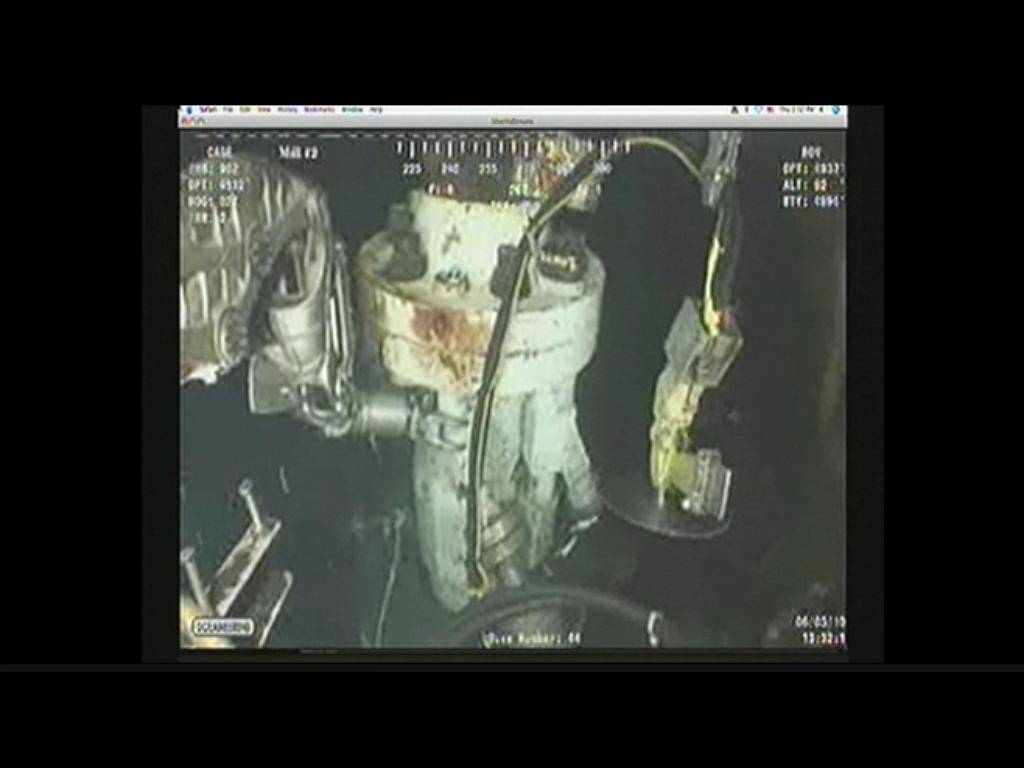

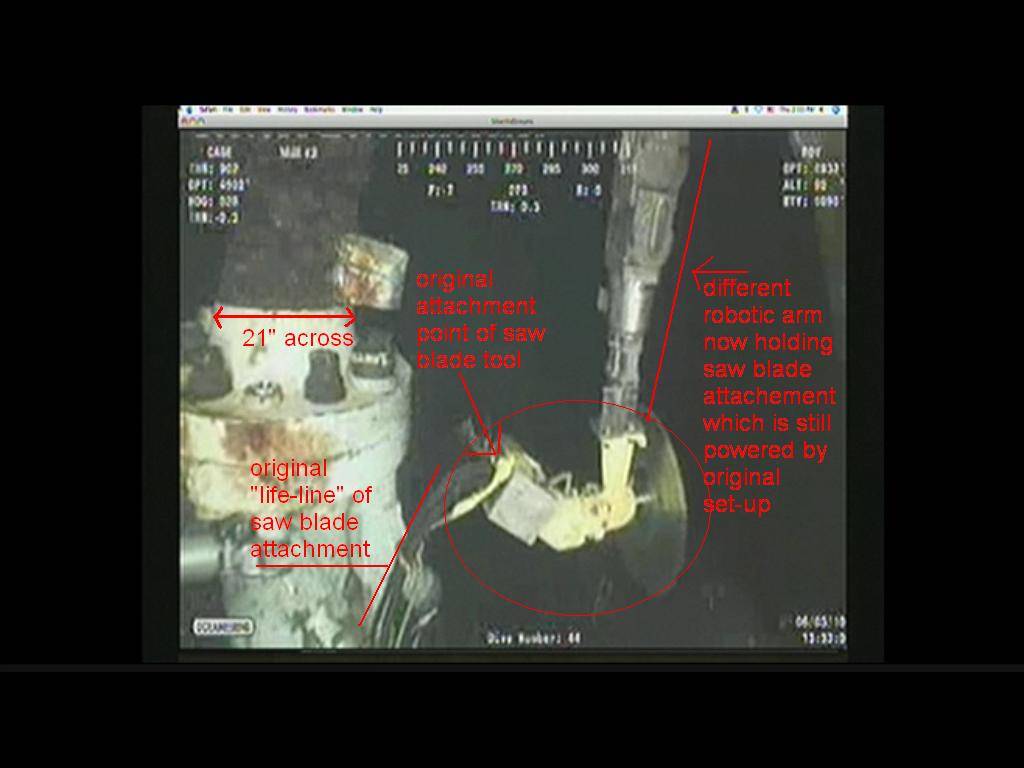

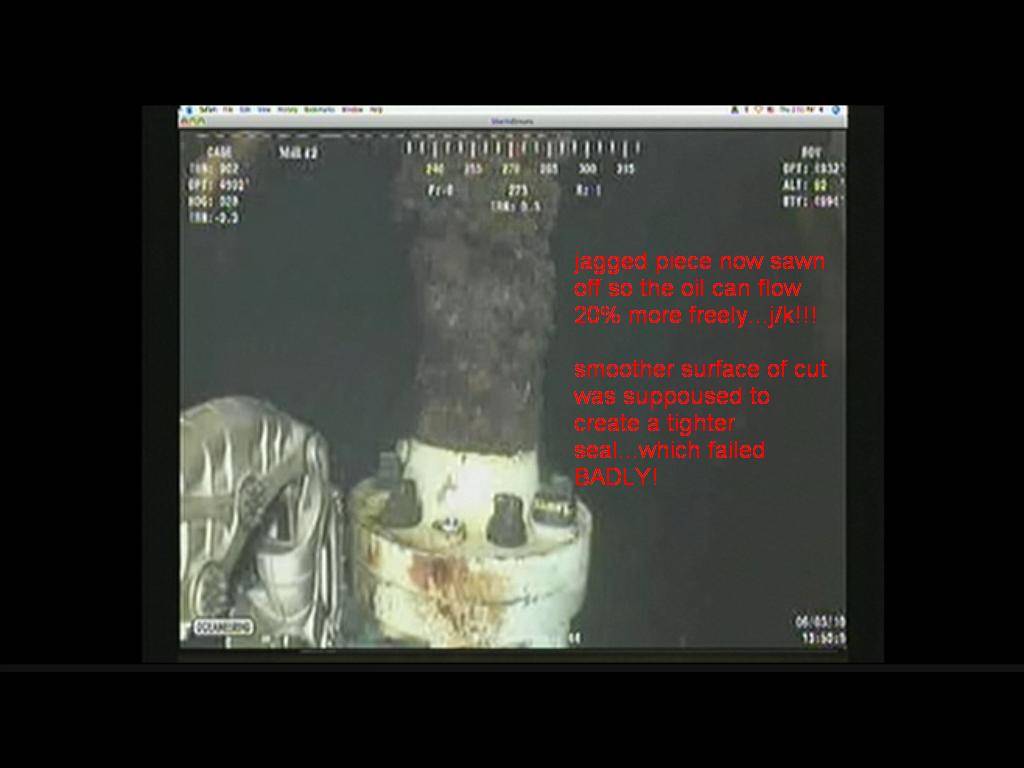

Another interesting day full of failures to stop or at least significantly slow down the flow of oil.

I took a few pictures of what was happening today and commented so the interested ones know what's up:

ICM makes the pics a certain size, if you have a hard time reading what I commented on the pics just click the bar on top of every pic to show it full size.

I took a few pictures of what was happening today and commented so the interested ones know what's up:

ICM makes the pics a certain size, if you have a hard time reading what I commented on the pics just click the bar on top of every pic to show it full size.