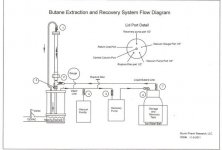

Have you considered fitting some "extension" tube at the bottom of the column so that the butane oil mixture can flow into the bottom of a teflon bag for evaporation? It's mighty nice not having to deal with the extra step of scraping or rinsing with alcohol.

Yes I have considered it, but haven't done it yet.

I read your excellent post on the subject and you certainly make it look attractive, so I will try it out!

Both of my down tubes go to the bottom of the pot, so it would be easy to do so.

Is Welsh Fluorocarbon still the best source that you have found to date to purchase Teflon bags?

http://www.welchfluorocarbon.com/TeflonPFAFEPModifiedPTFELayFlatBags.htm

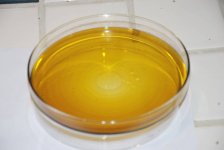

The reasons I haven't tried it yet, is that I redissolve much my BHO in alcohol anyway, so as to use freezing to coagulate the waxes, so that they can be easily filtered out.

I also am trying to develop our thin film BHO and thin film EtOh purging under vacuum processes, so have concentrated on those first.

Here is a picture of the bottom of my lid and one of a coffee filter used to filter out plant waxes from BHO after redissolving in EtOh and freezing overnight.