-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Haskel pneumatic refrigerant pumps

- Thread starter Gray Wolf

- Start date

Yup, the head uses an o'ring seal, so the gasket is reuseable.

Good afternoon all. I've been running my Haskel down in Eugene now for about three months I converted it to a single stage pump also. I'm finding it very difficult to pull a vac like many are taking about. Dave you mentioned earlier about putting some valves in place in order to switch between the two stages, any way you could post a diagram on how to set that up. Thank you for taking the time to research all of this for us. ive been running mine with two single phase 5hp do system compressors. 27 pounds of butane in 48 min yesterday just gets stuck once a vac needs to be achieved. Thank you Gw for your comitment in moving us forward, I've kearned a lot from these posts.

Good afternoon all. I've been running my Haskel down in Eugene now for about three months I converted it to a single stage pump also. I'm finding it very difficult to pull a vac like many are taking about. Dave you mentioned earlier about putting some valves in place in order to switch between the two stages, any way you could post a diagram on how to set that up. Thank you for taking the time to research all of this for us. ive been running mine with two single phase 5hp do system compressors. 27 pounds of butane in 48 min yesterday just gets stuck once a vac needs to be achieved. Thank you Gw for your comitment in moving us forward, I've kearned a lot from these posts.

Guna have to come check out this setup man. It was a pleasure meeting everybody yesterday. I plan on modifying this pump to run both single and two stage, I'll keep you posted.

Thank you GW i'm going to modify my pump tomorrow so i can run it single and dual. I just wanted to say one more time that you don't need a screw compressor to run a haskel. With the hard efforts of Dave From Northwest compressor, and the guys at HIS in portland we were able to get this done single phase two Dv systems 5hp compressors..

Thank you GW i'm going to modify my pump tomorrow so i can run it single and dual. I just wanted to say one more time that you don't need a screw compressor to run a haskel. With the hard efforts of Dave From Northwest compressor, and the guys at HIS in portland we were able to get this done single phase two Dv systems 5hp compressors..

Good point. It just needs 40 scfm at 100 psi of clean air, regardless of where you get it from.

I'm quite surprised at the lack of response here.....you guys realize what's being said and done? Single phase haskel in operation with the recovery times we've dreamed of......guess I'm the only one excited......

I feel like this is evidence that pneumatic recovery should be the base line for regulation here in Oregon

I feel like this is evidence that pneumatic recovery should be the base line for regulation here in Oregon

GratefulOne

Member

I feel like this is evidence that pneumatic recovery should be the base line for regulation here in Oregon

For what reasons? Why can't an electric driven pump work just as well?

icdog

Member

I'm quite surprised at the lack of response here.....you guys realize what's being said and done? Single phase haskel in operation with the recovery times we've dreamed of......guess I'm the only one excited......

I feel like this is evidence that pneumatic recovery should be the base line for regulation here in Oregon

I'm very excited by this but also somewhat confused.

Not very clear on what compressor runs the thing?

Does it need a refrigeration unit on the line? What if there isn't one what will happen?

There has been mention that it doesn't pull vac or not very well. We need to pull vac so how do we get around this?

I'd like to see pics of one setup.

Dave at Haskel

Active member

I'm very excited by this but also somewhat confused.

Not very clear on what compressor runs the thing?

Does it need a refrigeration unit on the line? What if there isn't one what will happen?

There has been mention that it doesn't pull vac or not very well. We need to pull vac so how do we get around this?

I'd like to see pics of one setup.

The Haskel EXT420 or 59025 does not have an electric motor on it (it uses no electricity), instead it gets it's operating energy from compressed air. The Haskel equipment doesn't require special drive air, just regular compressed air, however, it is better if it has been filtered to remove some of the water in the air. Haskel's recommended air cleanliness is Class 5, which is a dirt particles no larger than 40 microns, and a dewpoint of 45 deg F, or lower.

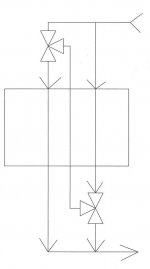

Regarding pulling a vacuum, the 59025-3-28000 is a two stage pump that does pull a vacuum, but has lower flow through it at higher pressures. The EXT420 is a single stage pump that has much higher flow with higher inlets, but (because it's single stage) doesn't do so well when pulling a vacuum. Gray Wolf uploaded a schematic that shows how to replumb an EXT420 to add a valve that allows the pump to be switched from single stage (when you need flow) and two-stage (when you want to pull a vacuum).

Dave

Dave at Haskel

Active member

Here is a quick photo shoot of how quickly and easily it is to convert the 59025-3 to a single stage, I could believe how easy it was....

Glad to hear it went well!

Dave

For what reasons? Why can't an electric driven pump work just as well?

Really? For number of reasons, I feel you should understand as much as you've been part of this conversation. TRS21 pumps have exploded, these Chinese attempts are cute at best. Any oiled pump is guaranteed to eventually contaminate.....shall I go on?

This has been the answer....thcland proved these "power limitations" are no longer a barrier to entry on pneumatic recovery systems....

Why spend 8k on an oven and 5k on a vacuum pump while using a cps or Appion.

GratefulOne

Member

You can run nearly any pump design from a rotating shaft. Air is a nice option since it also cools the pump but it can be done other ways.

The goal is a good pump that produces a clean final product. Anyway this can be done is a good solution. Why limit designers to air drives only?

Pumps currently in use for the majority of people extracting are not really the pumps used in factories (Haskel is an exception). Extractors could really benefit from other companies with real industrial designs setting up like Haskel is. Many designs do not use air drives.

A potential issue with air driven pumps is how clean is the air supply? Will oil residue transfer pass the seals like oiled pumps do? Maybe much slower rates. Getting supply air really clean takes equipment. Not super hard but is that being thought about? Are the transfer levels after simple cheap filters so low it does not matter?

I think the pump issue will continue to evolve. I just don't want engineers to be forced into a box by a rules making board. The rules should have general parameters. Any solution that gets you inside those parameters should work as well as any other.

The goal is a good pump that produces a clean final product. Anyway this can be done is a good solution. Why limit designers to air drives only?

Pumps currently in use for the majority of people extracting are not really the pumps used in factories (Haskel is an exception). Extractors could really benefit from other companies with real industrial designs setting up like Haskel is. Many designs do not use air drives.

A potential issue with air driven pumps is how clean is the air supply? Will oil residue transfer pass the seals like oiled pumps do? Maybe much slower rates. Getting supply air really clean takes equipment. Not super hard but is that being thought about? Are the transfer levels after simple cheap filters so low it does not matter?

I think the pump issue will continue to evolve. I just don't want engineers to be forced into a box by a rules making board. The rules should have general parameters. Any solution that gets you inside those parameters should work as well as any other.

I'm with grateful on this.

There's a number of hydrocarbon rated pumps out there that serve the industrial market, that can be driven a number of ways, corken comes to mind, but there are others. This is a market still on its infancy, but having a company like Haskell on our side is huge, it brings a level of competency to the table that wasn't often seen in the industry before the change in laws.

Dave I know the idea was floated before, but is there any plans for development of a electric motor driven ext420?

There's a number of hydrocarbon rated pumps out there that serve the industrial market, that can be driven a number of ways, corken comes to mind, but there are others. This is a market still on its infancy, but having a company like Haskell on our side is huge, it brings a level of competency to the table that wasn't often seen in the industry before the change in laws.

Dave I know the idea was floated before, but is there any plans for development of a electric motor driven ext420?

Not a dumb question, many people in a variety of industries have asked for an electrically driven Haskel pump. It's not a simple conversion, the Haskel air motor has a reciprocating motion (back and forth), while a normal motor has a rotary motion. Yes, there are devices that convert rotary motion into reciprocating, but it is more challenging than just that, one of the big benefits of a compressed air driven pump is that it automatically adjusts for changes in the load (pressure changes), while an electric motor can't do that. However, as I mentioned in another post, we are looking for an electric approach, which would include a battery powered approach.

Dave

What about an electromagnetically driven piston?

You can run nearly any pump design from a rotating shaft. Air is a nice option since it also cools the pump but it can be done other ways.

The goal is a good pump that produces a clean final product. Anyway this can be done is a good solution. Why limit designers to air drives only?

Pumps currently in use for the majority of people extracting are not really the pumps used in factories (Haskel is an exception). Extractors could really benefit from other companies with real industrial designs setting up like Haskel is. Many designs do not use air drives.

A potential issue with air driven pumps is how clean is the air supply? Will oil residue transfer pass the seals like oiled pumps do? Maybe much slower rates. Getting supply air really clean takes equipment. Not super hard but is that being thought about? Are the transfer levels after simple cheap filters so low it does not matter?

I think the pump issue will continue to evolve. I just don't want engineers to be forced into a box by a rules making board. The rules should have general parameters. Any solution that gets you inside those parameters should work as well as any other.

Yup, pneumatics are an expensive way to achieve our goals, because you only get about 4 scfm per horsepower, so we end up running a ten horse motor to do a job a 1 horse motor would be more than adequate for.

It does have other charms, like for instance it is inherently explosion proof.

You can stall it without any ill effects.

It is easy to operate at the higher pressures necessary for solvents like propane.

It is relatively high volume, compared to the Appion, Promax, TR-21, etc.

It will operate in dirty and poorly ventilated conditions that would kill one of the other pumps.

For the record, the extended body of the 59025 separates the two cylinders far enough that if one cylinder blows a seal, it doesn't contaminate the other.

The 59025-3 adapted for our use, also has the space between the two cylinders, plumbed so that any leaks can be captured or vented to a different location.

Pneumatic matic intensifiers aren't moving at the high speeds electric oil less compressors are, so run cooler and you don't need as much refrigeration to cool your gases back down.

A wonderful time proven design, it alas does suck from an air consumption stand point, which leaves the market window open for something oil less and explosion proof, not requiring 10 horsepower to run.

I also note that instead of holding a cross between themselves and our community like Appion, Haskel not only embraced our business, but rose to the challenge with the EXT-420 design, that we are currently sorting out and experimenting with plumbing solutions to realize its full single/dual stage capabilities.

I admire that in a company, and salute CPS for the same reason.

Why would we ever want to do further business with someone who doesn't want it, and fends it off, rather than rising to the occasion to better serve their customers needs?

My take is that the market window is large enough and still growing, that the selection of certified pumps will grow to fill that space soon.

Latest posts

-

-

-

-

-

Consumer poll for most popular payment form for seed purchases.

- Latest: moose eater

Latest posts

-

-

-

-

-

Consumer poll for most popular payment form for seed purchases.

- Latest: moose eater