-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

150w HPS Club and Resource Guide......

- Thread starter Pipedream

- Start date

DD, I know that my igniter being protected from the heat nets ZERO noise from my ballast save for a few seconds at startup. It is silent from then on even with the lid open.

bluebuds said:shady if it dosnt have to be perfectly round, the craft shops sell glass to go around candles and lanterns. they may be a little bigger on one end or fatter in the middle but im sure they will work the same. -bluebuds

I agree that the hurricane tubes are perfect for a medium base HPS bulb. Its hard to beat a $4 glass cooltube.

on a side note:

I found aluminium tape easier to use than 4" wormdrive clamps to attach my 4inch aluminium ducting to my hurricane tube glass cooltube.

Hoosierdaddy:

I'm feelin the custom ballast box

good work!

Shady Smoka

Active member

Thanks guys. Im gonna go ahead and build one of those.

Note to self: Dont touch hot bulb

Note to self: Dont touch hot bulb

Hey discoduck, looking nice ! You should be very happy with 3 out of 4. Could've been a whole lot worse.

Regarding my remote ballast of the floralux:

I hope that I will change my mind, but my preliminary results after running my remote ballasted floralux for 5 hours is pretty disappointing. I don't notice much of a difference at all in cabinet temperature ! The ballast is outside the cabinet and it's barely even warm. The bulb is clearly what is generating almost all of the heat. I obviously didn't make things worse by remote ballasting the floralux, but I'm not convinced that it helped a whole lot either. Like I said, my testing so far has been premature, so I might change my mind after running the HPS for a few days. I hope so.

Regarding my remote ballast of the floralux:

I hope that I will change my mind, but my preliminary results after running my remote ballasted floralux for 5 hours is pretty disappointing. I don't notice much of a difference at all in cabinet temperature ! The ballast is outside the cabinet and it's barely even warm. The bulb is clearly what is generating almost all of the heat. I obviously didn't make things worse by remote ballasting the floralux, but I'm not convinced that it helped a whole lot either. Like I said, my testing so far has been premature, so I might change my mind after running the HPS for a few days. I hope so.

Last edited:

DiscoDuck

Member

Thanks greenhead. Hang in there, as you said it didn't make things worse. Add a computer fan to "blow" the heat directly off the bulb and off the canopy. The fan doesn't cool the heat, it just mixes with the cooler air below the canopy and drops the temps a couple of degrees. If your intake is correctly tuned, the heated air should be exhausted before it makes an issue.

Try this for starters:

Open the door(s) of your box with the exhaust fan running. Listen to the speed of the fan closely, then shut the door(s). Does the fan speed increase? If so, the exhaust is attempting to expel the heated air while the intake isn't replacing that air fast enough, slowing down the whole process and heating the box. A negative pressure environment is what you want here but you don't want significant negative air so much that it causes your fan to overwork.

If you shut the door(s) and don't hear a noticeable difference in the exhaust fan speed, you're intake is probably ok.

Several other things to consider: (please forgive if being redundant)

Heat = rise

Cool = sink

It's not uncommon for air circulation to mix and overheat your cool air intake. Cool air is at the floor level so it's convenient to cut intakes on the floor or near the floor, ex. bottom panel or bottom of back panel. Heated air is best expelled through the top of the box or the upper part of the back panel.

My box doesn't have much headroom. Even though my intake and exhaust are separated as far as possible from each other, it's still possible for the intake to "suck" some of the heated exhaust air wafting out of the box.

I made a glorified manifold (half a shoe box) out of thin veneer. I attached the half box over the exhaust vent, this directs the heated exhaust up and away from the potential influence of the intakes.

Another potential band aid is to duct your intake to a cooler area if possible. Do you have any dark colors inside the box? White paint on surfaces seems to keep things cooler than darker colors. Good luck!

Duck

Try this for starters:

Open the door(s) of your box with the exhaust fan running. Listen to the speed of the fan closely, then shut the door(s). Does the fan speed increase? If so, the exhaust is attempting to expel the heated air while the intake isn't replacing that air fast enough, slowing down the whole process and heating the box. A negative pressure environment is what you want here but you don't want significant negative air so much that it causes your fan to overwork.

If you shut the door(s) and don't hear a noticeable difference in the exhaust fan speed, you're intake is probably ok.

Several other things to consider: (please forgive if being redundant)

Heat = rise

Cool = sink

It's not uncommon for air circulation to mix and overheat your cool air intake. Cool air is at the floor level so it's convenient to cut intakes on the floor or near the floor, ex. bottom panel or bottom of back panel. Heated air is best expelled through the top of the box or the upper part of the back panel.

My box doesn't have much headroom. Even though my intake and exhaust are separated as far as possible from each other, it's still possible for the intake to "suck" some of the heated exhaust air wafting out of the box.

I made a glorified manifold (half a shoe box) out of thin veneer. I attached the half box over the exhaust vent, this directs the heated exhaust up and away from the potential influence of the intakes.

Another potential band aid is to duct your intake to a cooler area if possible. Do you have any dark colors inside the box? White paint on surfaces seems to keep things cooler than darker colors. Good luck!

Duck

Last edited:

For safety reasons, I really try not to give electrical advice. The reason is not that I'm not confident in what I'm saying, but I never know if I'm being understood. However, in this case, I'm going to make an exception. PLEASE, PLEASE, PLEASE nobody take exception to what I'm about to say. I do this for everyone's safety....

I'm very sorry hoosierdaddy, but this is not a good idea. It violates one of the very basic rules of Electrical Engineering Design Safety.

If this unit is plugged in and you touch exposed plug, you are going to get knocked on your ass or maybe alot worse! When working with plugs and receptacles, the live or hot side should ALWAYS be a receptacle, never an exposed plug.

Pipedream, I tend to agree with you, but I would much rather get a little bite from a properly grounded device than to have an HID explode in someones face when they mistakenly plug it into a receptacle.

Actually, I should have added in my original explination to never hook up the power until your light is plugged in.

Also, do not stick your finger in your non-grounded reading lamp socket when there is no bulb and the power is on. (see where I'm going with this, Pipedream?)

Also, do not stick your finger in your non-grounded reading lamp socket when there is no bulb and the power is on. (see where I'm going with this, Pipedream?)

DiscoDuck said:Thanks greenhead. Hang in there, as you said it didn't make things worse. Add a computer fan to "blow" the heat directly off the bulb and off the canopy. The fan doesn't cool the heat, it just mixes with the cooler air below the canopy and drops the temps a couple of degrees. If your intake is correctly tuned, the heated air should be exhausted before it makes an issue.

Try this for starters:

Open the door(s) of your box with the exhaust fan running. Listen to the speed of the fan closely, then shut the door(s). Does the fan speed increase? If so, the exhaust is attempting to expel the heated air while the intake isn't replacing that air fast enough, slowing down the whole process and heating the box. A negative pressure environment is what you want here but you don't want significant negative air so much that it causes your fan to overwork.

If you shut the door(s) and don't hear a noticeable difference in the exhaust fan speed, you're intake is probably ok.

Several other things to consider: (please forgive if being redundant)

Heat = rise

Cool = sink

It's not uncommon for air circulation to mix and overheat your cool air intake. Cool air is at the floor level so it's convenient to cut intakes on the floor or near the floor, ex. bottom panel or bottom of back panel. Heated air is best expelled through the top of the box or the upper part of the back panel.

My box doesn't have much headroom. Even though my intake and exhaust are separated as far as possible from each other, it's still possible for the intake to "suck" some of the heated exhaust air wafting out of the box.

I made a glorified manifold (half a shoe box) out of thin veneer. I attached the half box over the exhaust vent, this directs the heated exhaust up and away from the potential influence of the intakes.

Another potential band aid is to duct your intake to a cooler area if possible. Do you have any dark colors inside the box? White paint on surfaces seems to keep things cooler than darker colors. Good luck!

Duck

Thanks DiscoDuck ! I'm not really having any ventilation probs in my cabinet. I have a few intakes on the bottom, an exhaust towards the top hooked up to a carbon filter and a few small fans inside the cabinet. The cabinet is sealed up pretty nicely and there is negative pressure, but not too much I think. The main issue that I was commenting on was that I didn't really notice any significant temperature drop by just placing the ballast outside of the cabinet. I think that I was just hoping for a bigger change. That was the main reason behind me remoting the ballast in the first place. I guess that one way for me to achieve a bigger drop in temperature would be to either use some sort of cooltube or to run a duct from the top of the fixture to the exhuast.

Last edited:

I'd been running the remote ballasted floralux for a couple of days now (18-6), and in regards to the cabinet temperature, things got even worse !

I was trying to figure out why in the hell the cabinet temperature was getting hotter AFTER removing the ballast from the cabinet ! That made no sense at all.

Well anyhow, I've figured out what the problem was, and it's now fixed.

After the ballast was removed, the fixture was a lot lighter, and I hung it using wires, which allows it to be lowered up & down. That was a mistake.

With the way my cabinet is setup, with the exhaust hole towards the top of one side, it's a much better idea to just keep the light up top, where it's on the same level as the exhaust.

So instead of lowering my light, I'll just continue to use stacks of CDS and move everything else up to lights instead, which is how I've been doing it on my previous grows.

I was trying to figure out why in the hell the cabinet temperature was getting hotter AFTER removing the ballast from the cabinet ! That made no sense at all.

Well anyhow, I've figured out what the problem was, and it's now fixed.

After the ballast was removed, the fixture was a lot lighter, and I hung it using wires, which allows it to be lowered up & down. That was a mistake.

With the way my cabinet is setup, with the exhaust hole towards the top of one side, it's a much better idea to just keep the light up top, where it's on the same level as the exhaust.

So instead of lowering my light, I'll just continue to use stacks of CDS and move everything else up to lights instead, which is how I've been doing it on my previous grows.

Last edited:

man pipe, everytime i see your wardrobe i get jealous  good news though, i got my stankonia and hashberry gettin kachopped right now... pics 2 follow...

good news though, i got my stankonia and hashberry gettin kachopped right now... pics 2 follow...

good news though, i got my stankonia and hashberry gettin kachopped right now... pics 2 follow...

good news though, i got my stankonia and hashberry gettin kachopped right now... pics 2 follow...

Indica Monkey

Member

New guy

New guy

Before we get down to business I'd like to thank PDB, SB2 and all the rest of you guys for putting in the effort - this is a great thread! I'm in the UK and about to build a 150w cab, I have all the parts I need laying around my cellar and I think now is a good time to start the build rather than putting it off any longer. I have to hand a 150w mh/hps/cmh ballast, 150w son t plus lamp, can 2600 filter, various silent pc fans, air pumps, water pumps, thermostats, timers, 2foot tube heater, etc etc etc. Are there any other UK basement 150watters in here? It'd be nice to have a rough idea of temps and air flow requirements before I start construction.

New guy

Before we get down to business I'd like to thank PDB, SB2 and all the rest of you guys for putting in the effort - this is a great thread! I'm in the UK and about to build a 150w cab, I have all the parts I need laying around my cellar and I think now is a good time to start the build rather than putting it off any longer. I have to hand a 150w mh/hps/cmh ballast, 150w son t plus lamp, can 2600 filter, various silent pc fans, air pumps, water pumps, thermostats, timers, 2foot tube heater, etc etc etc. Are there any other UK basement 150watters in here? It'd be nice to have a rough idea of temps and air flow requirements before I start construction.

DiscoDuck

Member

Hello Indica Monkey. Sounds like you have most of the stuff for a successful indoor grow! Temps and air flow requirements:

Passive intakes work best. Generally speaking, passive intakes should equal twice the exhaust size. If your exhaust fan has a 4" vent, you'll probably need about 8" of intake. I've read several 150 watt growers say their cab interior temperatures are only 6 degrees f. above ambient room temperature. Determine the average ambient temperature where the grow box will operate. Ideally the ambient temps will be six degrees f. lower than the ideal box temp, (several opinions on this ranging from high sixties to mid seventies f.) If your average ambient temps exceed growing conditions, you may have to consider more extensive ventilation for the ambient environment (basement), up to air conditioning. If temps are nice and cool in the basement then your heater may be enough to do the job. I'm not an expert on root temperatures but I'm certain a few peeps in this thread are. Anybody have a recommendation?

Assuming your ambient temps are acceptable, your exhaust fan size will relate to the overall interior cubic area of the grow box. Some folks prefer a fan about twice the otherwise rated capacity, due to scrubber air-flow reduction. If your computer fans are server caliber, they may work for exhausts, otherwise they'll be good for additional circulation. Computer fans are also good when used to blow on the hot grow bulb.

My cabinet is on the small side for a 150hps. My exhaust fan moves 95 cfm and is hooked to a speed controller. The speed controller is set to low, I don't know the adjusted cfm are but everything works. Some folks prefer a little more beef, the Dayton 265 cfm is popular. Another popular exhaust fan for indoor growers is the Stanley blower. Panasonic has one of the quietest lines of residential exhaust fans but I don't know if they're stiff enough to work with a scrubber. Centrifugal fans usually move the most air but can ruin stealth intentions. Squirrel cage/blower fans will move enough air and run quieter than a centri fan.

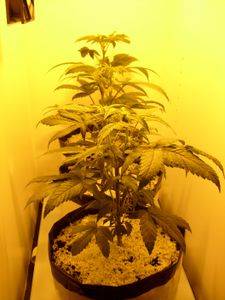

I'm not sure what your cab dimensions will be but 50 watts of HID light per square foot is average. If you plan to have a box with a larger than three square footprint, you might consider adding a cfl or two. 150s don't have a great deal of penetration but nobody ever told our resident OG, Pipedream. He's growin what look like four and five foot trees with a 150.

The only other item I recommend is a digi camera. Please post lots of pics, lol.

Passive intakes work best. Generally speaking, passive intakes should equal twice the exhaust size. If your exhaust fan has a 4" vent, you'll probably need about 8" of intake. I've read several 150 watt growers say their cab interior temperatures are only 6 degrees f. above ambient room temperature. Determine the average ambient temperature where the grow box will operate. Ideally the ambient temps will be six degrees f. lower than the ideal box temp, (several opinions on this ranging from high sixties to mid seventies f.) If your average ambient temps exceed growing conditions, you may have to consider more extensive ventilation for the ambient environment (basement), up to air conditioning. If temps are nice and cool in the basement then your heater may be enough to do the job. I'm not an expert on root temperatures but I'm certain a few peeps in this thread are. Anybody have a recommendation?

Assuming your ambient temps are acceptable, your exhaust fan size will relate to the overall interior cubic area of the grow box. Some folks prefer a fan about twice the otherwise rated capacity, due to scrubber air-flow reduction. If your computer fans are server caliber, they may work for exhausts, otherwise they'll be good for additional circulation. Computer fans are also good when used to blow on the hot grow bulb.

My cabinet is on the small side for a 150hps. My exhaust fan moves 95 cfm and is hooked to a speed controller. The speed controller is set to low, I don't know the adjusted cfm are but everything works. Some folks prefer a little more beef, the Dayton 265 cfm is popular. Another popular exhaust fan for indoor growers is the Stanley blower. Panasonic has one of the quietest lines of residential exhaust fans but I don't know if they're stiff enough to work with a scrubber. Centrifugal fans usually move the most air but can ruin stealth intentions. Squirrel cage/blower fans will move enough air and run quieter than a centri fan.

I'm not sure what your cab dimensions will be but 50 watts of HID light per square foot is average. If you plan to have a box with a larger than three square footprint, you might consider adding a cfl or two. 150s don't have a great deal of penetration but nobody ever told our resident OG, Pipedream. He's growin what look like four and five foot trees with a 150.

The only other item I recommend is a digi camera. Please post lots of pics, lol.

Latest posts

-

-

-

-

Giardinetto di Totò Indoor... Settimana VI Fio

- Latest: strain_hunter

Latest posts

-

-

-

-

Giardinetto di Totò Indoor... Settimana VI Fio

- Latest: strain_hunter