-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Off the shelf retail store screw-in LED and CFL bulb comparisons

- Thread starter blynx

- Start date

AgentPothead

Just this guy, ya know?

I think they are just using "water" as a catchall for "fluid". There are tons of things you can use to cool which have much lower boiling points than water, are basically chemically inert, and are non conductive. Heck Reiko-x's post reminded me of the computers they cool by literally dunking the whole thing into mineral oil.I don't know what this guy has in mind.

Probably something more like what Hooka and Reiko mentioned.

View Image

But if he were to install sealed strips inside of clear polycarbonate tubes, he could pump water through the tubes, connect flexible tubing to both ends then pump the hot water to a radiator installed outside the greenhouse.

Metal is expensive and corrodes and would probably be more expensive and complicated to install.

Perhaps even heavier too.

If you were to use food-grade stainless steel tubing inside the external heat exchanger as well as an inline reverse osmosis system you could keep the water crystal clear.

We're trying to beam photons through it.

If you were to keep the LED voltage below about 40 volts and mount the drivers above the water lines, it would be safer.

You could install a whole bunch if one-way valves to limit spillage when someone drives a forklift into the water system.

But it is just water, not ethylene glycol like in my car.

You could attach wires to the strips then dip them in clear polyurethane as a last step of manufacturing.

I don't think it would block too much light and it is really durable stuff.

I don't know how good it is at transferring heat but if would be a really thin coating.

AgentPothead

Just this guy, ya know?

The best way to waterproof a strip like that is with silicone, look up MG Chemicals 422B-340G it comes as a spray you can cover the lights and board once everything is wired.I forgot to mention that if there is no exposed metal then there will be no electricity in contact with the water.

That way there's no electrolysis and no corrosion.

My strips do have metal connection points but I could attach my wires then seal them up with silicone or something.

https://postimg.cc/8JszKWZ7View Image

I don't know about the surface of the LED though.

I know there's phosphorus in it but I'm assuming it has a layer of plastic on top ?

AgentPothead

Just this guy, ya know?

That's what a radiator is for to increase the surface area of the fluid to increase heat exchange.But then the water has to cool. In air. So probably not quite a big number as that. Unless you run a cold hose through it constantly. I don't know.

PCBuds

Well-known member

But then the water has to cool. In air. So probably not quite a big number as that. Unless you run a cold hose through it constantly. I don't know.

Yes, that's true but you move that hot water outside the grow area and use something like an air conditioning unit to remove the heat with forced air.

For a small home grow you would probably use a computer fan or blower but you would probably want to use a stainless steel heat exchanger to keep the water clean instead of copper.

I don't know if such a beast exists.

PCBuds

Well-known member

I think they are just using "water" as a catchall for "fluid". There are tons of things you can use to cool...

Yes but when the system fails like they always do, especially in my case, (Lol) then I'm just dumping water on my plant not oil or whatever.

I'm aiming for sustainable and no-till.

Mostly just cuz I'm lazy. Lol

PCBuds

Well-known member

... There are tons of things you can use to cool which have much lower boiling points than water, ...

I don't think you want a lower boiling point.

When something starts to boil it builds up vapor pressure and all your lines blow off spraying "coolant" everywhere.

PCBuds

Well-known member

PCBuds

Well-known member

Dont forget to take I to account the loss of photons due to the water and polycarbonate. Not to mention what it may do to the spectrum.

That's true but it may be negligible compared to how much brighter the LEDs could probably be.

Hey Ya’ll, I just posted some updates and 10 new pictures of my current 6 plants flowering under 612w of 5000k SIL’s. If you wanna look click the link in my Signature.

PCBuds

Well-known member

FRANKENBUDS

Member

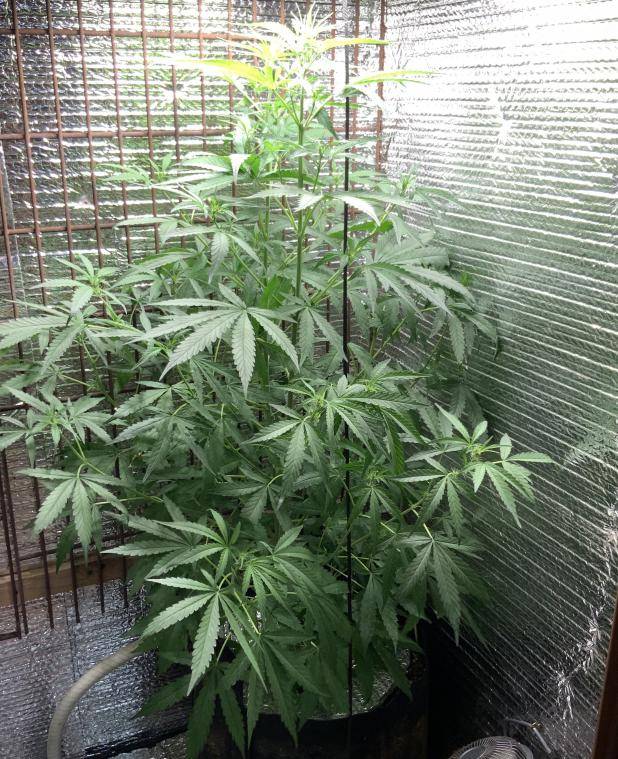

I rotated your picture for you.

[URL=https://i.postimg.cc/3RyWRSfp/20191216-183923.jpg]View Image[/url]

Seriously? 30 day veg soil? 60 watt? Nice

Boocoodinkydow

Active member

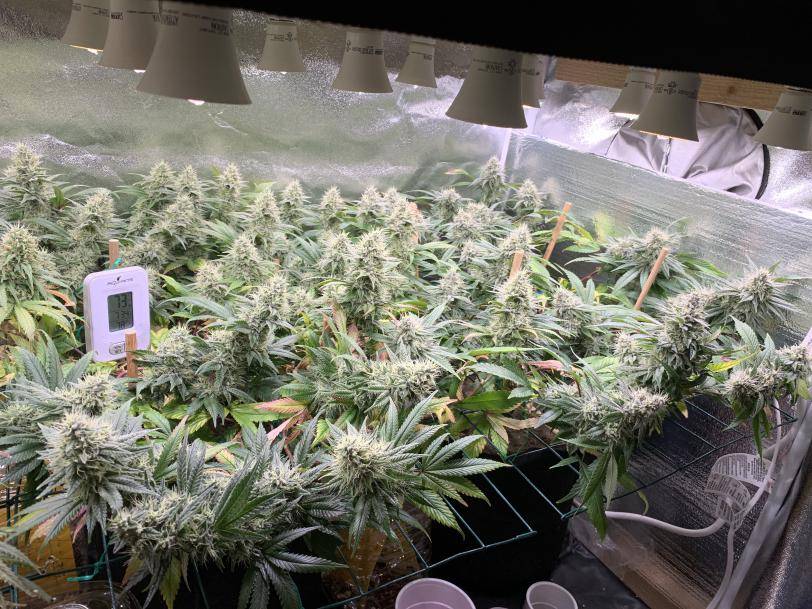

Can’t play with you boys any longer since I went vertical with 4’ led tubes but this is my present grow at 42 days under 73.5w of SIL using 12/12 from seed. Got me off to a good start. It was 39” here.

After about 3 more weeks with the vertices led tubes, this happened. 56” of lush growth.

After about 3 more weeks with the vertices led tubes, this happened. 56” of lush growth.

PCBuds

Well-known member

Can’t play with you boys any longer since I went vertical with 4’ led tubes...

I think it just makes sense.

Everyone has got a closet they can convert and then you don't have to force your plant to grow sideways.

Your plant looks awesome!!

Day 1 of week 6 flower all - 5000k 17w 1600lm

2 x GG

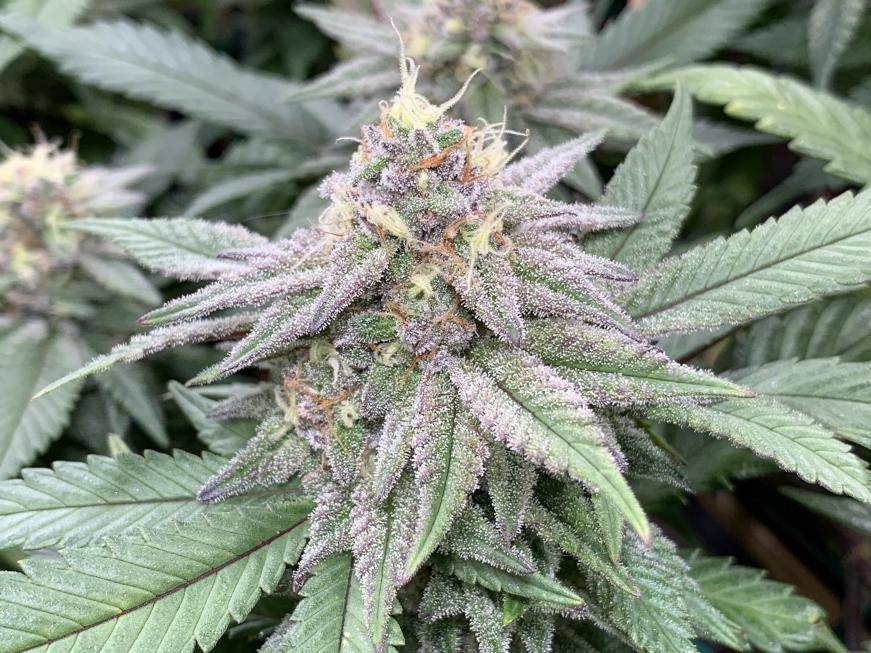

GG nug

Tangelo

Tangelo nug

Bottom row group shot. BG BG Tangelo.

2 x GG

GG nug

Tangelo

Tangelo nug

Bottom row group shot. BG BG Tangelo.

E

ESTERCHASER

frugal minds UNITE! ID love to rub a joint on those flowers omfg!