JG's Ghost

Active member

Hey guys:

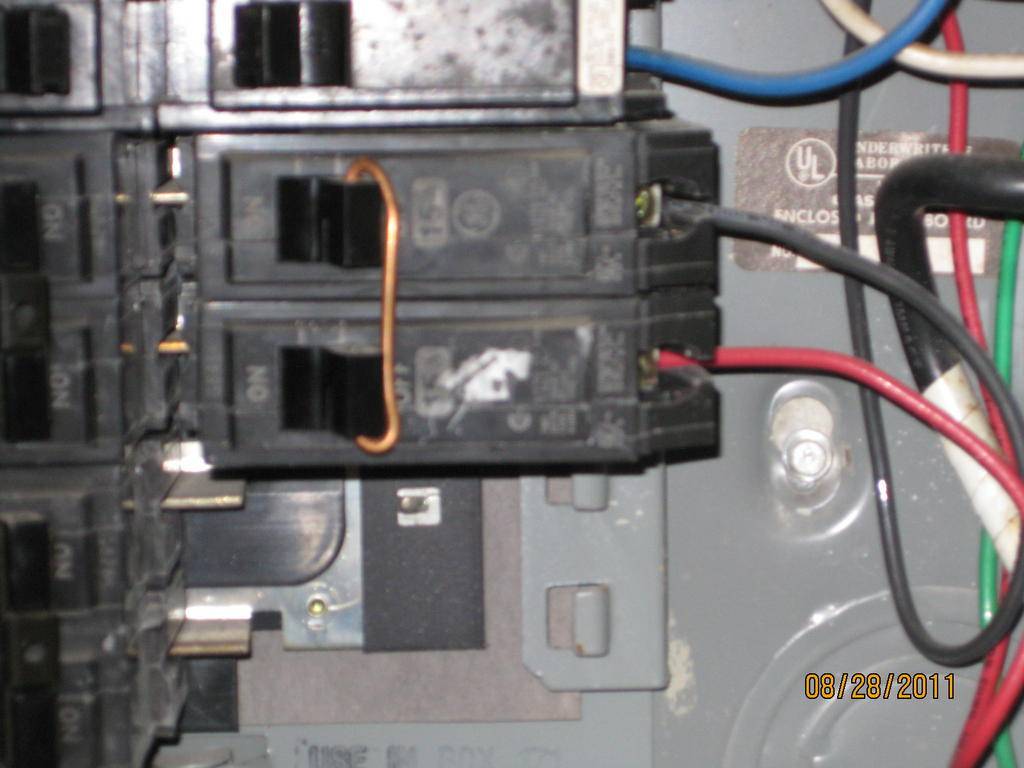

Remember this mess?...

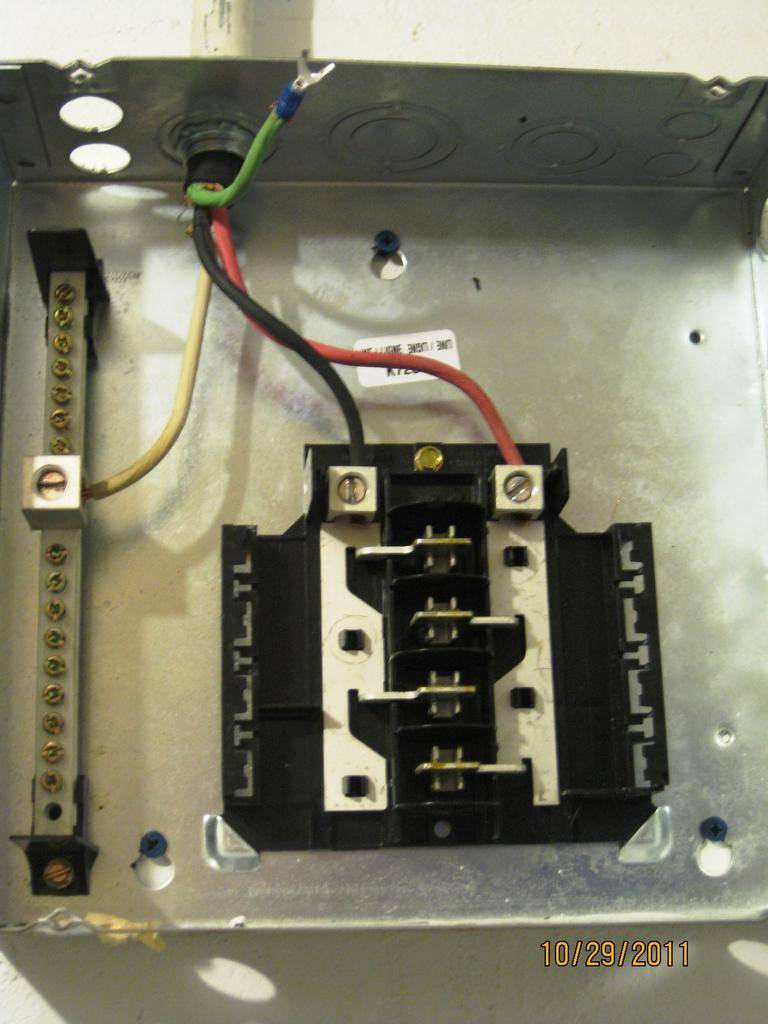

Well now it looks like this.......

A little better. Don't you think?

As you can see in the sub panel the green ground is not attached because there is nowhere to attach it. I'm just gonna drill a small hole, and use a self tapping screw.

I was finally able to get to the cool tubes, and they have no power wire at all. So I will need to run my own, but the ballasts have these weird assed plugs.

Anyone know where I can get the matching male side of this thing?

Thanks

JG

Remember this mess?...

Well now it looks like this.......

A little better. Don't you think?

As you can see in the sub panel the green ground is not attached because there is nowhere to attach it. I'm just gonna drill a small hole, and use a self tapping screw.

I was finally able to get to the cool tubes, and they have no power wire at all. So I will need to run my own, but the ballasts have these weird assed plugs.

Anyone know where I can get the matching male side of this thing?

Thanks

JG