Well thanks for stopping in, Also check back im going to update this tutorial this weekend to come! Going to add the ebb n flow screens to it as well as clamps on the returns!

-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blazeoneup's Recirculating Dwc Construction Tutorial!

- Thread starter blazeoneup

- Start date

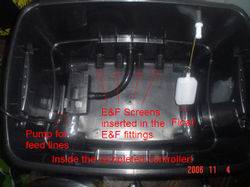

Ok guys i made a few needed changes in the new rebuild, I thought i would share them with you all. I tried to edit it into the tutorial the best i could but i am posting them here as well at the end of the thread

1. I installed ebb n flow screens to help prevent the roots from growing down into the return lines.

2. I used thread tape to insure a good seal on the threads of the ebb n flow fittings.

3. I used hose clamps to clamp the tubing to the fittings to insure 100% leak tight seal.

Now for pictures of the upgrades!

1. I installed ebb n flow screens to help prevent the roots from growing down into the return lines.

2. I used thread tape to insure a good seal on the threads of the ebb n flow fittings.

3. I used hose clamps to clamp the tubing to the fittings to insure 100% leak tight seal.

Now for pictures of the upgrades!

Hey Blaze, have you considered scrapping 90% of the plumbing altogether by placing each row in a plywood tank? You might want to add up the plumbing costs and consider it.

I'm just at the point of kicking the idea around so bear with me. The upside of this is you eliminate all potential plumbing leaks, all potential root blockage, and you can freely adjust bucket spacing when needed. The downside is it requires a lot more water (and nutes) - I'm trying to figure out the best way to lower the water volume in the tanks. I might just end up using rocks or bricks if I do this.

Another possible downside is how to make the tank water tight. If you go with epoxy, you have to use stuff certified for potable water systems, and that stuff is even more expensive than regular epoxy, which is insanely expensive to begin with. I'm thinking I'll just use poly tarps since they're waterproof. I'm sketchy about that since I don't know if they're really waterproof, or just "waterproof." No doubt I'll have to find out before I start.

Just an idea.

I'm just at the point of kicking the idea around so bear with me. The upside of this is you eliminate all potential plumbing leaks, all potential root blockage, and you can freely adjust bucket spacing when needed. The downside is it requires a lot more water (and nutes) - I'm trying to figure out the best way to lower the water volume in the tanks. I might just end up using rocks or bricks if I do this.

Another possible downside is how to make the tank water tight. If you go with epoxy, you have to use stuff certified for potable water systems, and that stuff is even more expensive than regular epoxy, which is insanely expensive to begin with. I'm thinking I'll just use poly tarps since they're waterproof. I'm sketchy about that since I don't know if they're really waterproof, or just "waterproof." No doubt I'll have to find out before I start.

Just an idea.

If i done all that it would take up way to much floor space. I assure you i have 2 systems, a 20 bucket system, and a 16 bucket system running right now, Both systems are leak tight and sealed very well.

So no i have not thought of putting them into a tank of any kind, Besides that this system i have is built with no epoxy lol, Or any glues ect for that matter and it is leak tight.

So no i have not thought of putting them into a tank of any kind, Besides that this system i have is built with no epoxy lol, Or any glues ect for that matter and it is leak tight.

G

Guest

Kick-ass Blaze, love watching you do your thing. You always give us a killer show and all the kickass DIY stuff. Thanks for sharing all your info and grow with us.

Thanks alot,

BG

Thanks alot,

BG

blazeoneup said:If i done all that it would take up way to much floor space. I assure you i have 2 systems, a 20 bucket system, and a 16 bucket system running right now, Both systems are leak tight and sealed very well.

So no i have not thought of putting them into a tank of any kind, Besides that this system i have is built with no epoxy lol, Or any glues ect for that matter and it is leak tight.

The floor space wouldn't be much different. The biggest difference is the amount of extra water and nutes needed and the decrease in needed plumbing. If I do build it it won't have any glues or epoxy either, just a plywood tank held together with screws, and some kind of liner for waterproofing (tarp or pond liner).

Last edited:

Dude if you built a system like the one built in the updated tutorial, Using the ebb n flow screens, and 3/4" tubing and wrapped thread tape around the threads of the bulkheads, Plus used hose clamps to clamp the hoses the the fittings you would find you have a leak tight system that can be moved around a little its fully flexible  And it is light proofed with no worries on light leaks, Or ways to deal with them plus its just so pretty and clean

And it is light proofed with no worries on light leaks, Or ways to deal with them plus its just so pretty and clean

Aeric thanks and yeah simple but helps improve the seal even though without it they dont leak

Aeric thanks and yeah simple but helps improve the seal even though without it they dont leak

Hmm, I forgot about lightproofing the water. Oops, algae galore. That might be the deal breaker.blazeoneup said:Dude if you built a system like the one built in the updated tutorial, Using the ebb n flow screens, and 3/4" tubing and wrapped thread tape around the threads of the bulkheads, Plus used hose clamps to clamp the hoses the the fittings you would find you have a leak tight system that can be moved around a little its fully flexibleAnd it is light proofed with no worries on light leaks, Or ways to deal with them plus its just so pretty and clean

Aeric thanks and yeah simple but helps improve the seal even though without it they dont leak

G

Guest

Great tutorial...Too bad I dont have an extra room to setup this size of a system

buddymag00

Member

nice work beautifuly illustrated . people like you make the learning curve really easy to handle .thanks blaze genius design.

dj digigrow

Active member

Do you have both systems running in 1 location?

If so, how many watts total are you running?

and whats your total dried weight average with both sysytems(16&20)?...

Thanks for the great info!!

If so, how many watts total are you running?

and whats your total dried weight average with both sysytems(16&20)?...

Thanks for the great info!!

dj digigrow

Active member

???

HydroCulture

Member

Hey blazeonup, great thread! Are these Ball-Valves in your system 100% leak tight? I have encountered quite a few ball valved that would slightly leak especially when twisted to on/off..

Come on guys, Do you really think i would be running multiple dwc systems if they leaked all over?

Once again and for the last time, This system doesnt leak not 1 bit from anywhere no valves no nothing. That is precisely why i used hose clamps to clamp off the tubing to all fittings!

Once again and for the last time, This system doesnt leak not 1 bit from anywhere no valves no nothing. That is precisely why i used hose clamps to clamp off the tubing to all fittings!

Trichome Toker

Member

A hose clamp just clamps your flex tube onto your barbs nice and tight right?

I might invest in some of those for piece of mind.

I don't use any now & I have no leaks, the tube fits nice and snug on the barb, but they seem like a smart idea.

I might invest in some of those for piece of mind.

I don't use any now & I have no leaks, the tube fits nice and snug on the barb, but they seem like a smart idea.

They are extra precaution! Yeah they just clamp the tubing to the barb!

Trichome Toker

Member

Probably especially useful if you like to trip over your tubing like me.

Yeah if you have ever tripped over the tubing jerking it off or shifting enough to cause a leak the clamps will prevent it