As many of the DIY guys, I used GODs instructions (and I mean KNNAs for the LEDs and VerdantGreen for the MJ Gardening).

but as KNNA was busy and couldnt be reached this winter I had to source my LEDs from other sources. I mainly used DealExtreme for 5Watt Whites running at 700mA (no brand though, and right now you could find better deals elsewhere), and Cree for Red and Royal Blue (both running at 550mA sourced from cutter ).

for vegetative I used 3W, 3B, and 6R all running at 630mA mounted on 3 PC heatsinks, totaling 28W at the plug

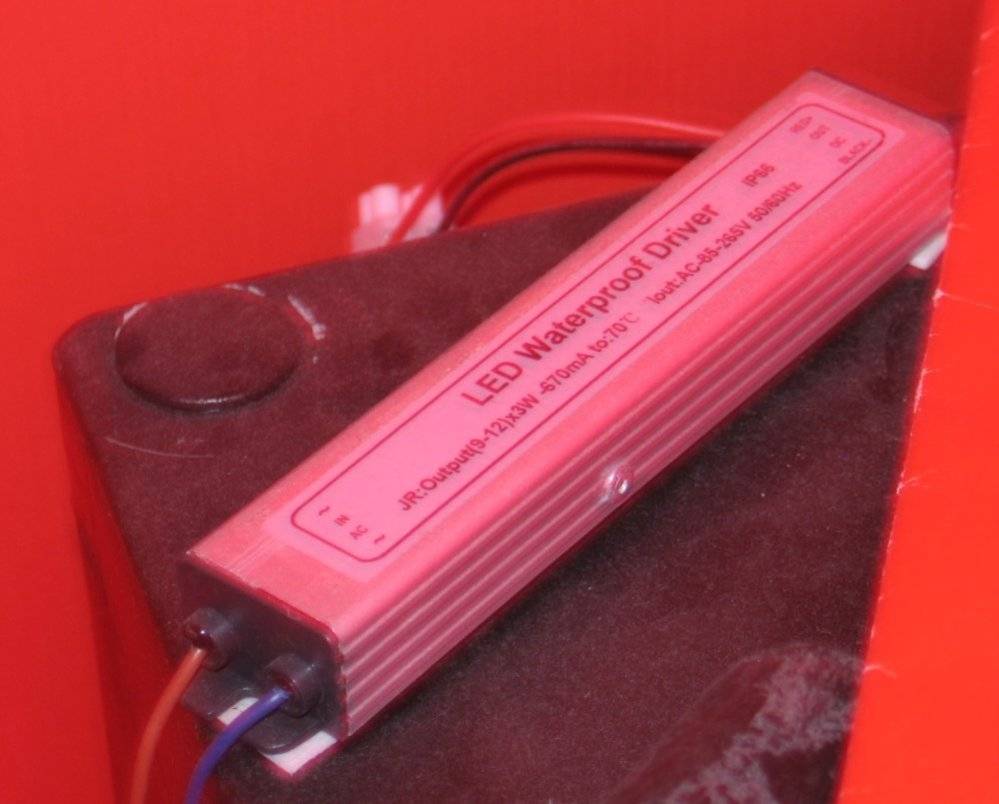

To be accurate it stabilises to 28 after 20minutes, as the noname dealextrem driver start from 31W -starting voltage at around 42V dropping to 38V after 20-30minutes, I dont know why, the meanwells dont have that kind of behaviour ).

Passive cooling, temperatures reaching 48C for REDs (they are a little bit overdriven at 630 as max is 700mA), 42C for the blues (as they have max 1000mA) and 58C for whites (they are infirior quality to CREE and have a nominal current at 700mA, so I thought running at 630mA is not overdriving, so the temperatures are ok. No fans apart from exhaust fan (12cm PC fan, regulated at 7V), just passive cooling for the heatsink (well maybe a small fan would be good in vegetative but I dont like the added noise)

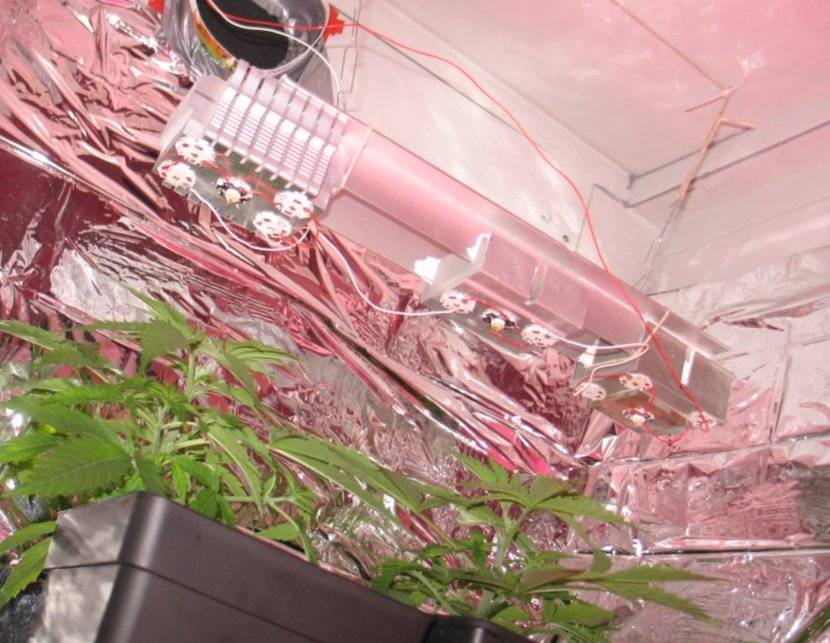

as for the construction, as you can see, I used 2 pieces of aluminum profile with thermal glue in order to connect the 3 Heatsinks together, but Im not very satisfied with the temperatures achieved. The 2 profiles connecting the 3 heatsinks also warm up, but that doesnt mean much. If I had to go over again, I would use aluminum profiles and spread the LEDs over a bigger area. That way I would certainly have lower temperatures, as PC heatsinks are not very good for passive cooling.

The 2 big ones were rated for around 65W but without a fan this capacity is greatly reduced.

in the flowering compartment. I used 28R 4B and 5W . The whites were running at 700mA, and the blue/red on two parallel strings under a meanwell at 1100mA (so 550mA each string).

How to calculate your Constant current supply

first you have to choose your LEDs. Example. I used 28R 4B 5W . 28R Cree XPE, 4B Cree XPE, and 5White chinese 5w each.

Reds are working at around 550-600mA (max700) and 2,1Volts.

Blue are working around 700mA (max1000mA) at 3,3V.

Whites are working at 700mA at 6,5V

so all in all I need 28*2,1V+4*3,3V+5*6,5V=104,5V to give some head room make it 107-108.

I also need 700mA for White/Blue and 550-600mA for Reds which makes life a little bit complicated.

Now we have to choose the drivers. I went for meanwells which are stable. We are trying to get as little as possible parallel strings and if we make 2 parallel strings we use exactly the same leds on each string in order not to have any unbalanced effects.

So I chose to use 1 700ma,20W driver for the White ones and then I chose an ELN60 (60w) running at 1,2A with 2 strings of 14Reds and 2Blues each. So each string would get 550mA which is underdriving the blues, but for 4 blues I didnt want to spare an extra driver. I put a correct fuse (630mA) before each string and everything was set.

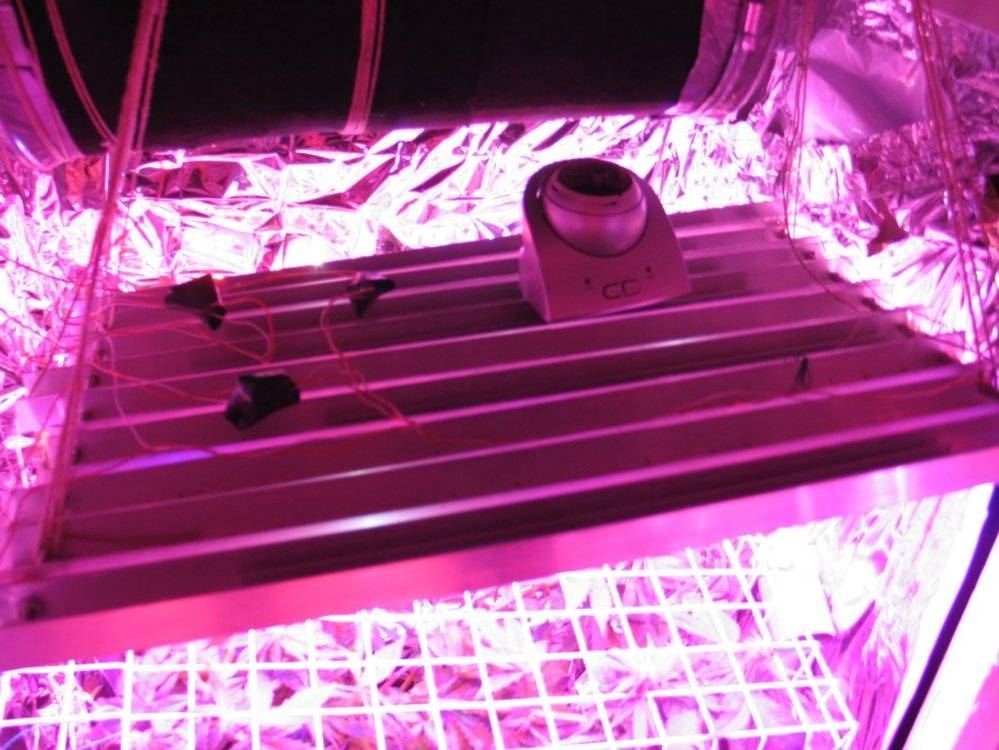

Heatsink Construction

I have some time so I'll give some more instructions on construction. I used aluminum profiles as heatsink. I used Π profiles measuring 2x3,5x2. That gives me (3,5x2+2x2+2x2)=15cm2 of surface area per cm of length used. I went for around 100cm2 per Watt as I wanted to mount a mostly passive system. I cut the profiles to 50cm each (my cabinet has 60cm of width), so 50*15=750cm2 of total area per cutted profile = around 7watt per profile.

Then I made 2 10mm holes on each side and put a 8mm threaded rod secured with nuts. On 4 profiles that I had to put more Watts, I glued with thermal glue in the center a smaller Π profile (1,5x1x1,5cm).

and led temperature never goes over 42C for Blue, 43C for Red and 46C for Whites which is fine. Just passive cooling and one 12cm PC exhaust fan on a DIY carbon scrubber (but it needs replacing)

Ιn this run I m driving the flowering compartment at 59W total at the plug and we will see the results (hopefully they will be the same).

the flowering took nearly 65days.

each string is protected with a fuse and a zener, but in my experience meanwell drivers are as stable as Pyramids. I wouldnt say the same for the deal extreme piece, but it was cheap and quite suitable to my needs (the meanwell running at 700mA would be too much for the Reds)

im not very proud of my construction skills but it works.

(this was the plant 10days before harvest)

For the future Im thinking of putting a low RPM fan circulating air in each cabinet. That is more in order to heat a little bit more the sativa dominant plants, than to cool the heatsinks. Temperatures in the cabinet are around 20-22 in flowering and 22-25 in vegetative, which I think are on the down side of the Cannabis spectrum

If you have any questions please fire away. and if anyone needs help building such a thing, dont hesitate to ask.

as for the sources

Cutter in Australia is very helpfull and the prices are right.Cutter.com.au

is very helpfull and the prices are right.Cutter.com.au

Led Teille in ebay has quite cheap chinese White and Blue LED. Less than 1eur per 3watt led which of course are not as good as the Cree and Osrams , but on the other hand they are dirty cheap.

and for the meanwells constant current regulators the cheapest source I found in Europe was Proconnect

but as KNNA was busy and couldnt be reached this winter I had to source my LEDs from other sources. I mainly used DealExtreme for 5Watt Whites running at 700mA (no brand though, and right now you could find better deals elsewhere), and Cree for Red and Royal Blue (both running at 550mA sourced from cutter ).

for vegetative I used 3W, 3B, and 6R all running at 630mA mounted on 3 PC heatsinks, totaling 28W at the plug

To be accurate it stabilises to 28 after 20minutes, as the noname dealextrem driver start from 31W -starting voltage at around 42V dropping to 38V after 20-30minutes, I dont know why, the meanwells dont have that kind of behaviour ).

Passive cooling, temperatures reaching 48C for REDs (they are a little bit overdriven at 630 as max is 700mA), 42C for the blues (as they have max 1000mA) and 58C for whites (they are infirior quality to CREE and have a nominal current at 700mA, so I thought running at 630mA is not overdriving, so the temperatures are ok. No fans apart from exhaust fan (12cm PC fan, regulated at 7V), just passive cooling for the heatsink (well maybe a small fan would be good in vegetative but I dont like the added noise)

as for the construction, as you can see, I used 2 pieces of aluminum profile with thermal glue in order to connect the 3 Heatsinks together, but Im not very satisfied with the temperatures achieved. The 2 profiles connecting the 3 heatsinks also warm up, but that doesnt mean much. If I had to go over again, I would use aluminum profiles and spread the LEDs over a bigger area. That way I would certainly have lower temperatures, as PC heatsinks are not very good for passive cooling.

The 2 big ones were rated for around 65W but without a fan this capacity is greatly reduced.

in the flowering compartment. I used 28R 4B and 5W . The whites were running at 700mA, and the blue/red on two parallel strings under a meanwell at 1100mA (so 550mA each string).

How to calculate your Constant current supply

first you have to choose your LEDs. Example. I used 28R 4B 5W . 28R Cree XPE, 4B Cree XPE, and 5White chinese 5w each.

Reds are working at around 550-600mA (max700) and 2,1Volts.

Blue are working around 700mA (max1000mA) at 3,3V.

Whites are working at 700mA at 6,5V

so all in all I need 28*2,1V+4*3,3V+5*6,5V=104,5V to give some head room make it 107-108.

I also need 700mA for White/Blue and 550-600mA for Reds which makes life a little bit complicated.

Now we have to choose the drivers. I went for meanwells which are stable. We are trying to get as little as possible parallel strings and if we make 2 parallel strings we use exactly the same leds on each string in order not to have any unbalanced effects.

So I chose to use 1 700ma,20W driver for the White ones and then I chose an ELN60 (60w) running at 1,2A with 2 strings of 14Reds and 2Blues each. So each string would get 550mA which is underdriving the blues, but for 4 blues I didnt want to spare an extra driver. I put a correct fuse (630mA) before each string and everything was set.

Heatsink Construction

I have some time so I'll give some more instructions on construction. I used aluminum profiles as heatsink. I used Π profiles measuring 2x3,5x2. That gives me (3,5x2+2x2+2x2)=15cm2 of surface area per cm of length used. I went for around 100cm2 per Watt as I wanted to mount a mostly passive system. I cut the profiles to 50cm each (my cabinet has 60cm of width), so 50*15=750cm2 of total area per cutted profile = around 7watt per profile.

Then I made 2 10mm holes on each side and put a 8mm threaded rod secured with nuts. On 4 profiles that I had to put more Watts, I glued with thermal glue in the center a smaller Π profile (1,5x1x1,5cm).

and led temperature never goes over 42C for Blue, 43C for Red and 46C for Whites which is fine. Just passive cooling and one 12cm PC exhaust fan on a DIY carbon scrubber (but it needs replacing)

Ιn this run I m driving the flowering compartment at 59W total at the plug and we will see the results (hopefully they will be the same).

the flowering took nearly 65days.

each string is protected with a fuse and a zener, but in my experience meanwell drivers are as stable as Pyramids. I wouldnt say the same for the deal extreme piece, but it was cheap and quite suitable to my needs (the meanwell running at 700mA would be too much for the Reds)

im not very proud of my construction skills but it works.

(this was the plant 10days before harvest)

For the future Im thinking of putting a low RPM fan circulating air in each cabinet. That is more in order to heat a little bit more the sativa dominant plants, than to cool the heatsinks. Temperatures in the cabinet are around 20-22 in flowering and 22-25 in vegetative, which I think are on the down side of the Cannabis spectrum

If you have any questions please fire away. and if anyone needs help building such a thing, dont hesitate to ask.

as for the sources

Cutter in Australia

is very helpfull and the prices are right.Cutter.com.au

is very helpfull and the prices are right.Cutter.com.auLed Teille in ebay has quite cheap chinese White and Blue LED. Less than 1eur per 3watt led which of course are not as good as the Cree and Osrams , but on the other hand they are dirty cheap.

and for the meanwells constant current regulators the cheapest source I found in Europe was Proconnect