G

guest 77721

Fan's and Scrubbers

Fan's and Scrubbers

One of the key features of a good growbox design is fitting a carbon scrubber to the ventilation system.

Let's take a look at CANFAN's stuff. They publish decent spec's with their equipment.

I'd like to fit a 6" CANFAN which is rated at 269 CFM with 1.5" WC pressure. This is a workhorse of a fan. http://www.canfilters.com/fan_metal_home.html

Now let's get a nice CANFAN 50 that's rated at 420CFM @ 0.75"WC.

http://www.canfilters.com/canfilters_50.html

Hey this sounds pretty good, I think I can get 270 CFM out of this combo, maybe? Well let's take a look.

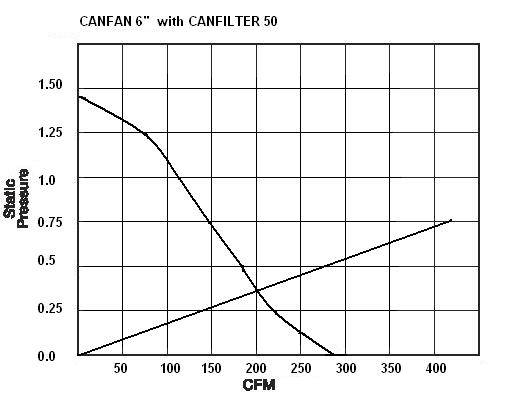

The operating point for the 6" CANFAN/50 combo is around 200CFM. Canfan says 210 CFM so that's close with about a 25% loss due to the scrubber. So what gives, the filter is supposed to give 420CFM @ 0.75" and we have a 1.5" Fan, how did we end up running at 50% of the scrubber and 75% of the fan? This is where the fan curve is needed to see how both these components make a system where the actual airflow is the operating point where the two curves cross.

Let's hook this puppy and see what happens. Holy cow this thing is loud. No wonder, look at the noise spec. 6 Sonnes, that's like 70 dB. Look up 70db, its a vaccuum cleaner loud or the same as radio or TV music. And that's the noise of the fan, the fan spec's don't include the air rushing though the ducts either.

Am I happy. Let's see I just spent at least $300 on this stuff, my cabinet is 90* and I can here this thing on the street.

So what are my options. Add a speed controller, box runs hotter. Get a quieter fan, if it's less that 1.5"WC, the box runs hotter. Downsize the lights? Leave the door open?

Every growbox you see fitted with a scrubber/fan combination is using this brute force approach to the ventilation. This is caveman engineering by Fred and Barney.

An alternative is to run unrestricted quiet fans to cool the lights. A high airflow, low noise computer fan will run with 15-25 db which is whisper quiet compared to this hoover. Add a second small fan pushing through a small scrubber and you're set. Cool, quiet and smell free.

Fan's and Scrubbers

One of the key features of a good growbox design is fitting a carbon scrubber to the ventilation system.

Let's take a look at CANFAN's stuff. They publish decent spec's with their equipment.

I'd like to fit a 6" CANFAN which is rated at 269 CFM with 1.5" WC pressure. This is a workhorse of a fan. http://www.canfilters.com/fan_metal_home.html

Now let's get a nice CANFAN 50 that's rated at 420CFM @ 0.75"WC.

http://www.canfilters.com/canfilters_50.html

Hey this sounds pretty good, I think I can get 270 CFM out of this combo, maybe? Well let's take a look.

The operating point for the 6" CANFAN/50 combo is around 200CFM. Canfan says 210 CFM so that's close with about a 25% loss due to the scrubber. So what gives, the filter is supposed to give 420CFM @ 0.75" and we have a 1.5" Fan, how did we end up running at 50% of the scrubber and 75% of the fan? This is where the fan curve is needed to see how both these components make a system where the actual airflow is the operating point where the two curves cross.

Let's hook this puppy and see what happens. Holy cow this thing is loud. No wonder, look at the noise spec. 6 Sonnes, that's like 70 dB. Look up 70db, its a vaccuum cleaner loud or the same as radio or TV music. And that's the noise of the fan, the fan spec's don't include the air rushing though the ducts either.

Am I happy. Let's see I just spent at least $300 on this stuff, my cabinet is 90* and I can here this thing on the street.

So what are my options. Add a speed controller, box runs hotter. Get a quieter fan, if it's less that 1.5"WC, the box runs hotter. Downsize the lights? Leave the door open?

Every growbox you see fitted with a scrubber/fan combination is using this brute force approach to the ventilation. This is caveman engineering by Fred and Barney.

An alternative is to run unrestricted quiet fans to cool the lights. A high airflow, low noise computer fan will run with 15-25 db which is whisper quiet compared to this hoover. Add a second small fan pushing through a small scrubber and you're set. Cool, quiet and smell free.