i vaped a bunch of co2 last night, in my Solo vape, and it was nice!

the taste is awesome , and the effects noticeable.

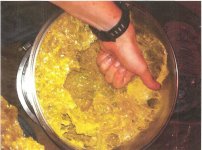

Its from BPG and ive had it for about a year in my drawer and it was just as nice as the day i bought it. The company is Canna Medicinals, the oil comes in a syringe and has a dark amber color.

the taste is awesome , and the effects noticeable.

Its from BPG and ive had it for about a year in my drawer and it was just as nice as the day i bought it. The company is Canna Medicinals, the oil comes in a syringe and has a dark amber color.