Red-

I haven't grown indoors for a few years and my previous grow was of "brute force" design, as you like to say. I had the luxury of doing that in the other garden because it was in a basement with no security/stealth concerns.

Well, I'm building a new closet and a new mother/veg cab and this thread has been a godsend man. Thank you so much.

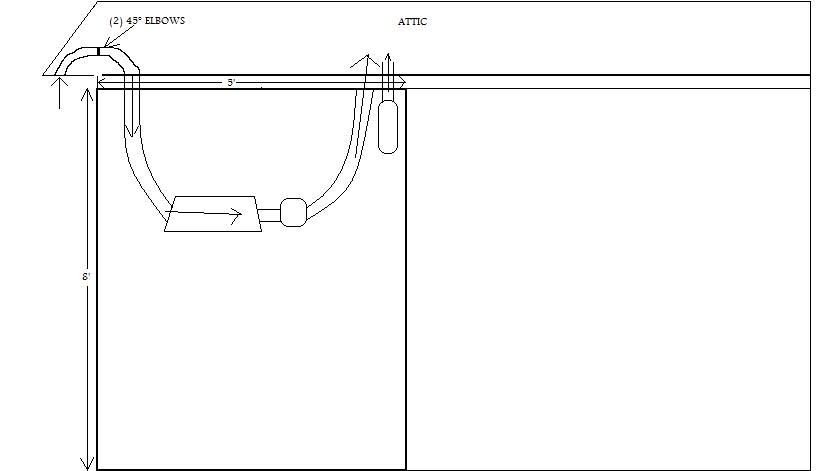

I *think* everything is making sense and have come up with this rudimentary drawing of my plans. Would you mind glancing it over and just let me know if there are any glaring errors or miscalculations?

The flowering closet will be 6' tall, 4' wide, 20" deep. The upper shelf is how the closet comes from the factory; removing/moving it would require modifications. Not counting this upper shelf, the actual grow area is about 55 CF.

I have a nice piece of lantern glass that I plan to make into a cooltube, but I would be willing to consider partitioning off the 400W HPS with glass the way you do in your cabinet, but I just can't think of a good work-around for the fact that my scrubber (which is 2' long... big DIY one...) will be in the upper chamber and I'd have to somehow run ducting THRU the section housing the HID.

Thanks and

I haven't grown indoors for a few years and my previous grow was of "brute force" design, as you like to say. I had the luxury of doing that in the other garden because it was in a basement with no security/stealth concerns.

Well, I'm building a new closet and a new mother/veg cab and this thread has been a godsend man. Thank you so much.

I *think* everything is making sense and have come up with this rudimentary drawing of my plans. Would you mind glancing it over and just let me know if there are any glaring errors or miscalculations?

The flowering closet will be 6' tall, 4' wide, 20" deep. The upper shelf is how the closet comes from the factory; removing/moving it would require modifications. Not counting this upper shelf, the actual grow area is about 55 CF.

I have a nice piece of lantern glass that I plan to make into a cooltube, but I would be willing to consider partitioning off the 400W HPS with glass the way you do in your cabinet, but I just can't think of a good work-around for the fact that my scrubber (which is 2' long... big DIY one...) will be in the upper chamber and I'd have to somehow run ducting THRU the section housing the HID.

Thanks and