Hephaestus

Member

G'day all,

Well, title seems appropriate Time to build a new cabinet; one for me, one for a friend in need (he's mechanically useless - last time he picked up a drill, he was in a cast for 3 months; and the scar is impressive!).

Time to build a new cabinet; one for me, one for a friend in need (he's mechanically useless - last time he picked up a drill, he was in a cast for 3 months; and the scar is impressive!).

Material, recycled... Jobsite rejects

Scored about 200' of this great 20ga prefinished steel - broken into a ] shape - 24" with 2" returns each piece 10' long. Rejected - because it's powdercoat is just a weeeeee bit off... So off to the dumpster it went... Makes for a nice box if you ask me

Makes for a nice box if you ask me  Geeze architects and their shades of grey...

Geeze architects and their shades of grey...

Then there I am "managing by walking around" today Ok, so I was making puppies... Screwing the pooch... Y'know Dogfucking!

Ok, so I was making puppies... Screwing the pooch... Y'know Dogfucking!  (it's nice to be the boss)

(it's nice to be the boss)  And there's all these nice 5x10 sheets of 1/4" clear plexi going into the dumpster. Had to ask... Someone will have to fill me in some day - I can't tell the difference between plexiglass and acrylic - I thought they were just different trade names... Zoink... Into the truck those go... Love those architectural rejects

And there's all these nice 5x10 sheets of 1/4" clear plexi going into the dumpster. Had to ask... Someone will have to fill me in some day - I can't tell the difference between plexiglass and acrylic - I thought they were just different trade names... Zoink... Into the truck those go... Love those architectural rejects

So I'm kinda stuck with the 24x24" base - Thinking 36" tall, Give up the top 6" as room to hide the mechanicals; Use PL-L's for light (have to see if I can get those 80w ones) - Only need a couple inches vertical for those; vented separately.

Note quite sure how I'm going to manage the front door(s) - it'd help if I owned a shear/brake... Then it would be simple...

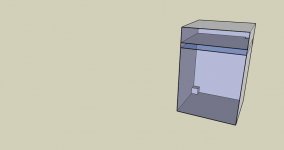

Here's my initial badly drawn sketchup drawing of what I'm thinking... Welcome any advise / suggestions

Well, title seems appropriate

Material, recycled... Jobsite rejects

Scored about 200' of this great 20ga prefinished steel - broken into a ] shape - 24" with 2" returns each piece 10' long. Rejected - because it's powdercoat is just a weeeeee bit off... So off to the dumpster it went...

Makes for a nice box if you ask me

Makes for a nice box if you ask me  Geeze architects and their shades of grey...

Geeze architects and their shades of grey...Then there I am "managing by walking around" today

Ok, so I was making puppies... Screwing the pooch... Y'know Dogfucking!

Ok, so I was making puppies... Screwing the pooch... Y'know Dogfucking!  (it's nice to be the boss)

(it's nice to be the boss)  And there's all these nice 5x10 sheets of 1/4" clear plexi going into the dumpster. Had to ask... Someone will have to fill me in some day - I can't tell the difference between plexiglass and acrylic - I thought they were just different trade names... Zoink... Into the truck those go... Love those architectural rejects

And there's all these nice 5x10 sheets of 1/4" clear plexi going into the dumpster. Had to ask... Someone will have to fill me in some day - I can't tell the difference between plexiglass and acrylic - I thought they were just different trade names... Zoink... Into the truck those go... Love those architectural rejects

So I'm kinda stuck with the 24x24" base - Thinking 36" tall, Give up the top 6" as room to hide the mechanicals; Use PL-L's for light (have to see if I can get those 80w ones) - Only need a couple inches vertical for those; vented separately.

Note quite sure how I'm going to manage the front door(s) - it'd help if I owned a shear/brake... Then it would be simple...

Here's my initial badly drawn sketchup drawing of what I'm thinking... Welcome any advise / suggestions

And now we blaze...

And now we blaze... Reworked the cabinet... Completely

Reworked the cabinet... Completely