-

As of today ICMag has his own Discord server. In this Discord server you can chat, talk with eachother, listen to music, share stories and pictures...and much more. Join now and let's grow together! Join ICMag Discord here! More details in this thread here: here.

-

ICMag and The Vault are running a NEW contest in October! You can check it here. Prizes are seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

passive plant killer

- Thread starter delta9nxs

- Start date

T

the_baked_chef

delta9nxs said:my philosophy on container media is that it is the mechanical properties that are most important. after that chemical reactions. use the materials around you. there are probably things available locally to you that would function well.

I think you're right. I will make my first try with coco (or peat moss) and perlite. We'll see how that turns out and later i will have time to try pumice instead of the perlite.

Thanks again...

I think you're right. I will make my first try with coco (or peat moss) and perlite. We'll see how that turns out and later i will have time to try pumice instead of the perlite.

Thanks again...

of the two, coco or peat moss, i think you are better off with coco because of the tendency for peat to drive ph down.

i have been asked a question via pm that i think should be answered for everyone.

i'm going to drag out that old flow diagram i made.

i have been running a separate pump bucket since i started the auto/pulsed watering.

at the time i made it i knew it was better to run like this but i had not really thought much about why. it was almost intuitive.

we have had quite a few folks build variations without using a separate pump chamber. and they work. but they will allow ec to climb as they let too much new solution into the control bucket each time the pump fires. this, in turn, also moves ph around.

in this scenario when the pump is in the control bucket and it fires it immediately causes a full draw down of the control bucket. this causes an immediate, strong intake to occur through the float valve from the volume tank. all fresh solution. at some point the excess from the plant reservoirs back flows into the control bucket and the system comes to equilibrium. the problem is that it causes an overfilling to occur that is above the float valve level setting.

when a separate pump bucket is used and the pump fires it causes an immediate draw down of the pump bucket only and a slow draw down of the control bucket. this allows the liquid returning from the individual plant reservoirs time to return to the control bucket before a strong draw occurs from the volume tank.

the pump bucket slowly fills from the control bucket during the time between pulses.

what all this does is limit the amount of fresh solution that is inputted with each pulse cycle.

this diagram should be looked at and understood because of it's effect on long term solution stability. i just whacked a plant that had been in flower in the same container with no change outs or add backs other than that occurring from blending and re-blending solution automatically. it was 857 ppm at the .5 conversion and the ph was 5.9.

this is after nine weeks of continuous growing at an input of 750 ppm @ about 5.6 ph.

i understand that, in some situations, space is the limiting factor and running another container for the pump may be impossible to achieve.

but if you have the room you are better off using a separate pump chamber. especially those growing in bigger rooms with multiple plants and maybe a perpetual harvest scheme.

editing to add that the connection between the plant reservoirs and the control bucket flows both ways. you can pulse so much that it will flow one way between pulses but i don't think that is a good idea. i think that the reverse flow, which in my case right now occurs for about ten minutes each hour, is beneficial for controlling salt build up in the medium. it is another form of movement.

i was thinking about the different forms of movement that occur in a ppk. pulse from the top, sub-irrigation from the bottom, evaporation via convection, and constant molecular motion. although not readily apparent to the eye there is motion all the time.

so, i have thought of perhaps yet another small improvement that i will work on and report later.

i am currently pulsing a quart once per hour. 6 gals per day per plant. this is obviously far more than the plant can consume but we are watering the medium, not the plant. the solution is extremely stable.

i'm going to drag out that old flow diagram i made.

i have been running a separate pump bucket since i started the auto/pulsed watering.

at the time i made it i knew it was better to run like this but i had not really thought much about why. it was almost intuitive.

we have had quite a few folks build variations without using a separate pump chamber. and they work. but they will allow ec to climb as they let too much new solution into the control bucket each time the pump fires. this, in turn, also moves ph around.

in this scenario when the pump is in the control bucket and it fires it immediately causes a full draw down of the control bucket. this causes an immediate, strong intake to occur through the float valve from the volume tank. all fresh solution. at some point the excess from the plant reservoirs back flows into the control bucket and the system comes to equilibrium. the problem is that it causes an overfilling to occur that is above the float valve level setting.

when a separate pump bucket is used and the pump fires it causes an immediate draw down of the pump bucket only and a slow draw down of the control bucket. this allows the liquid returning from the individual plant reservoirs time to return to the control bucket before a strong draw occurs from the volume tank.

the pump bucket slowly fills from the control bucket during the time between pulses.

what all this does is limit the amount of fresh solution that is inputted with each pulse cycle.

this diagram should be looked at and understood because of it's effect on long term solution stability. i just whacked a plant that had been in flower in the same container with no change outs or add backs other than that occurring from blending and re-blending solution automatically. it was 857 ppm at the .5 conversion and the ph was 5.9.

this is after nine weeks of continuous growing at an input of 750 ppm @ about 5.6 ph.

i understand that, in some situations, space is the limiting factor and running another container for the pump may be impossible to achieve.

but if you have the room you are better off using a separate pump chamber. especially those growing in bigger rooms with multiple plants and maybe a perpetual harvest scheme.

editing to add that the connection between the plant reservoirs and the control bucket flows both ways. you can pulse so much that it will flow one way between pulses but i don't think that is a good idea. i think that the reverse flow, which in my case right now occurs for about ten minutes each hour, is beneficial for controlling salt build up in the medium. it is another form of movement.

i was thinking about the different forms of movement that occur in a ppk. pulse from the top, sub-irrigation from the bottom, evaporation via convection, and constant molecular motion. although not readily apparent to the eye there is motion all the time.

so, i have thought of perhaps yet another small improvement that i will work on and report later.

i am currently pulsing a quart once per hour. 6 gals per day per plant. this is obviously far more than the plant can consume but we are watering the medium, not the plant. the solution is extremely stable.

Last edited:

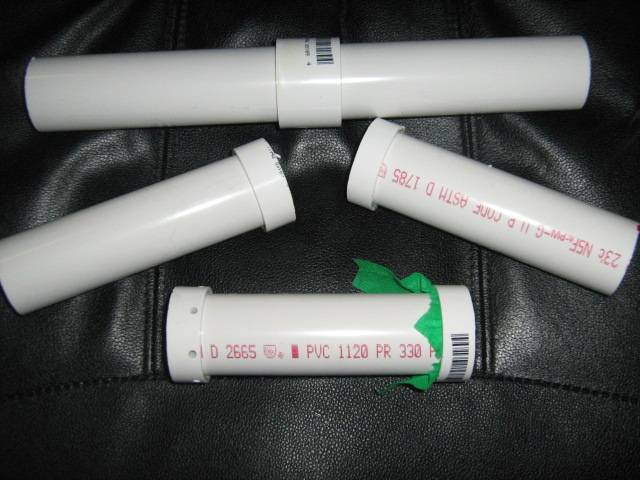

just a few shots to show how i'm building the pulse terminal. it's all self explanatory but i started with 2 13.5" lengths of 1/2" pvc pipe. you then find center at 6.75". move 2.5" out from center along a straight line to drill the pipe 5" apart. i like these holes to be 7/16".

then drill the holes for the john guest fitting 1.5" out from center. these should be a precision 3/8" at right angles to the 7/16" holes. remember that you are drilling lefts and rights, mirror image.

for the fitting i use the same tubing i use for everything else which is 3/8" od. it is a very tight press fit into the pvc tubing. the short pieces protrude from the fitting 1/2".

this delivers a quart very evenly in 15 seconds with my 950 gph magdrive on 4 sites.

i apologize for the very bad photos. i'll be getting a nice camera soon.

the john guest fittings are at lowes in the same aisle with the faucet repair parts. this is a 3/8" T.

then drill the holes for the john guest fitting 1.5" out from center. these should be a precision 3/8" at right angles to the 7/16" holes. remember that you are drilling lefts and rights, mirror image.

for the fitting i use the same tubing i use for everything else which is 3/8" od. it is a very tight press fit into the pvc tubing. the short pieces protrude from the fitting 1/2".

this delivers a quart very evenly in 15 seconds with my 950 gph magdrive on 4 sites.

i apologize for the very bad photos. i'll be getting a nice camera soon.

the john guest fittings are at lowes in the same aisle with the faucet repair parts. this is a 3/8" T.

Last edited:

gregor_mendel

Active member

That's fast and friendly service D9, thanks!

On the 3/8" outside diameter tubing, is that RO tubing (polyethylene) or vinyl tubing, such as for irrigation?

I have some blue 3/8" OD RO tubing in my hand, and it seems pretty stiff. It is 1/4" ID, and of course, 1/16" wall.

On the 3/8" outside diameter tubing, is that RO tubing (polyethylene) or vinyl tubing, such as for irrigation?

I have some blue 3/8" OD RO tubing in my hand, and it seems pretty stiff. It is 1/4" ID, and of course, 1/16" wall.

DIY Media Wick

DIY Media Wick

Using plumbing parts was gonna cost too much so I DIY'ed the Media Wick from some 1.5 inch PVC tubing, and a coupler. I cut 6.5inch tubes and inserted them into the coupler for stability. Then sawed them in half with the Miter saw. They fit very snugly, and wont slip off when loaded. I drilled holes in the top peice to avoid a half inch res. Then used the other half to hold the thin piece of fabric, to hold the Media. I cut the hole in the bottom of the bucket just a little small to hold the tube snuggly in place. I am very pleased with the outcome.

Free Bucket

leftover fabrick (free)

$0.30 tubing

$0.49 coupling

$0.79 per plant site!....

Peace!

Peace!

DIY Media Wick

Using plumbing parts was gonna cost too much so I DIY'ed the Media Wick from some 1.5 inch PVC tubing, and a coupler. I cut 6.5inch tubes and inserted them into the coupler for stability. Then sawed them in half with the Miter saw. They fit very snugly, and wont slip off when loaded. I drilled holes in the top peice to avoid a half inch res. Then used the other half to hold the thin piece of fabric, to hold the Media. I cut the hole in the bottom of the bucket just a little small to hold the tube snuggly in place. I am very pleased with the outcome.

Free Bucket

leftover fabrick (free)

$0.30 tubing

$0.49 coupling

$0.79 per plant site!....

Peace!

Peace!zeke99

Active member

I've been using what is known as 'aluminum lint traps' for a screen at the end of the tailpipe.

It's basically a piece of aluminum that is easy to cut from the original shape.

This is a good example of what it looks like:

http://www.google.com/products/cata...a=X&ei=IqR-TrDZBITx0gGcqO3bDw&ved=0CFUQ8gIwBA

Out of the package, they are flat. Inexpensive. Easy to work with. I've been using tape to get them on the tailpipes and than plumbers goop to keep them on.

It's basically a piece of aluminum that is easy to cut from the original shape.

This is a good example of what it looks like:

http://www.google.com/products/cata...a=X&ei=IqR-TrDZBITx0gGcqO3bDw&ved=0CFUQ8gIwBA

Out of the package, they are flat. Inexpensive. Easy to work with. I've been using tape to get them on the tailpipes and than plumbers goop to keep them on.

That's fast and friendly service D9, thanks!

On the 3/8" outside diameter tubing, is that RO tubing (polyethylene) or vinyl tubing, such as for irrigation?

I have some blue 3/8" OD RO tubing in my hand, and it seems pretty stiff. It is 1/4" ID, and of course, 1/16" wall.

hey, gregor mendel! i used this tubing for both the sub-irrigation/drain line and the pulse feeder. it is pretty stiff but you can't crush it shut with a heavy object like you can with vinyl.

usplastics sells the 500' roll only but you can buy shorter lengths from other sources.

i also use it from the volume tanks to the control buckets so you need float valves sized to receive this diameter tubing. i used item # 23135

editing to correct float valve part #. 23135 is the correct one. thanks, bloyd!

http://www.usplastic.com/catalog/item.aspx?itemid=24997&catid=707

item # 58145

Last edited:

hey, medscientist, i've got a miter saw that has never cut a piece of wood. but it has been used a lot. i could start a landfill with the pvc i've butchered up. the holes in the top of the tube you put in to drain excess need to be at least 3/16" in diameter to avoid forming a capillary block. 1/4" is better. maybe 5/16" because they will be filled with medium.

zeke, i've never seen those before. check for corrosion after the first plant. unless it's anodized aluminum it will corrode.

zeke, i've never seen those before. check for corrosion after the first plant. unless it's anodized aluminum it will corrode.

Stranger

Member

For a debris filter at the end of the media wick, I just got a few pairs or my wife's old nylons and cut the toes out and tie wrapped them covering the opening at the bottom of my down pipes. I am glad I did because with the turface/perlite some particles could have fallen through the tie wrap screen and clogged my feeder tubes. I will be increasing diameter of all tubes after this run.

Like the new pulse top d9x, I had something similar in mind, of course mine had more pieces and was complicated

Like the new pulse top d9x, I had something similar in mind, of course mine had more pieces and was complicated

Thanks Delta. I'll check for that every week.... Maybe pantyhose are a good option.

since i already had the ties installed on the tailpieces i have been putting a small piece of fiberglass window screen in the tailpiece from the inside.

gregor_mendel

Active member

Thanks again D9!

Since we are already using the LLDPE line, I was pondering using John Guest fittings at the lower bucket. It would be a bulkhead using a 1/4" MNPT to John Guest 3/8" with an npt nut on the inside, with fabricated gasket. (like an ebb and flow fitting/bulkhead)

I suppose you may have already thought of or done that.

Do you see any disadvantage to this?

It does seem like your latex over LLDPE design can probably take a ridiculous amount of abuse without accidental disconnecion.

I have also never had such a through hole without minor leaks, and the tire valve does seem like an excellent solution.

I have already purchased buckets and tire valves - just typing out loud here.

I appreciate your dedication to this thread and your system.

gregor_mendel

Since we are already using the LLDPE line, I was pondering using John Guest fittings at the lower bucket. It would be a bulkhead using a 1/4" MNPT to John Guest 3/8" with an npt nut on the inside, with fabricated gasket. (like an ebb and flow fitting/bulkhead)

I suppose you may have already thought of or done that.

Do you see any disadvantage to this?

It does seem like your latex over LLDPE design can probably take a ridiculous amount of abuse without accidental disconnecion.

I have also never had such a through hole without minor leaks, and the tire valve does seem like an excellent solution.

I have already purchased buckets and tire valves - just typing out loud here.

I appreciate your dedication to this thread and your system.

gregor_mendel

Thanks again D9!

Since we are already using the LLDPE line, I was pondering using John Guest fittings at the lower bucket. It would be a bulkhead using a 1/4" MNPT to John Guest 3/8" with an npt nut on the inside, with fabricated gasket. (like an ebb and flow fitting/bulkhead)

I suppose you may have already thought of or done that.

Do you see any disadvantage to this?

It does seem like your latex over LLDPE design can probably take a ridiculous amount of abuse without accidental disconnecion.

I have also never had such a through hole without minor leaks, and the tire valve does seem like an excellent solution.

I have already purchased buckets and tire valves - just typing out loud here.

I appreciate your dedication to this thread and your system.

gregor_mendel

hi, gregor, i've thought about using those fittings and i see nothing negative in using them but i've never had a tire valve connection leak. the tire valves are so incredibly cheap.

i used tire valves 30 years ago in salt water specimen holding tanks as air line fittings.

i bought a new 3/16"cobalt tipped bit i only use for drilling out the tire valve seats. it drills a lot smoother if you use a drop of vegetable oil on the bit each time.

I don't think I understand how you installed those ties onto the end of the tailpiece.

drill 8 1/8" holes near the lower end

stick four ties through the 8 holes, through one side and out the corresponding opposite hole

take four more ties and slide the lock/ratchet thingy on the first set to hold them in place.

cut the ties off, both the excess of the ties through the holes and the entire tie part off the lock/ratchet.

Last edited:

After I drilled the sidewall holes, I had to change the fabric to vynil screen in the wick, to increase the speed of drain. I also used the screen in the bottom of the buckets to cover the holes. I will raise the sideholes on the next bucket to allow for a little more liquid in the bucket without coming out the sides. She reaches equilibrium very quickly.

@catman...

maybe...topic (pumice,alternative mediums) previously posted about in this thread... maybe

member ~SYK~ posted about mediums:

the `ch0wmix` was coc0/hydrot0n. or, when some kbs`ers went to media instead of full kbs... /or to show/pr0ve trees could be done w/ handwater soiless, w/out bell+whistle of an active system...

many in these far-away-galaxy days use c0co/perlyte, now... not many use 100persent perlyte or 100persent pumice....

maybe found or able to find perlyte/pumice mix to be good mix... lots of air space, never too much water, drainage, 100persent reusable, maybe....

other options include

1/4in gravel (@ any scapeland place), aquarium gravel, washed stone, perlyte (works very well)... if no coco, peat moss, if no peat moss, bark mulch... mixed w/ perlyte... or, by itself...

...pumice, like perlyte, is liteweight volcanic rox. pumice has harder composition, does not compact in lower part of container as much as perlyte, heavier than perlyte (less floating)... can be either handwater daily, or automated feed continuous, pulse, etc... @ end of season, 100persent of pumice held in container 100persent reusable... water+nutrients held in crax of rox... full drainage w/ enough water retained for day/more of moisture... 1/16in, or smallest can find, best... regular gravel 1/4in- work, too, just heavier... @ every scapeland-type place...

hope this helps

...pumice... maybe works very well... smallest size 1/4-1/16in. (the common type @ any scapeland place)... mixed 50/50 w/ perlyte, no need to ever use any other media. re-use, etc... 100persent perlyte works well, too...catman said:*mistress* - I was wondering if you knew where one should look for agricultural grade pumice?

maybe...topic (pumice,alternative mediums) previously posted about in this thread... maybe

member ~SYK~ posted about mediums:

when posting about tree gardening in KBS (a tek of lore,formerly @ og, maybe in some older ic threads, maybe)...~SYK~ said:I think your question is about media - so that is what I will discuss :

Lava : Original Medium, Wicks and Drains well, ph unstable, hard to wash, hard to disinfect, heavy to move/clean/dispose

Hydroton: I have never seen a successful Killer Bucket Grow ran wtih Hydroton. I personally ran it once, and ended up transplanting my plants into Lava (of all things) half way thru to save the crop!

Coir: Used on its own, it holds too much moisture in large pots Killer Bucket Size.

Coir/Hydroton 40/60 mix : VERY Successful. Many growers used this medium and were very happy with the results. The advantages of large plants without the disadvantages of a constant watering system and built in buffers to error.

Coir/Perlite : Never saw this used. IMO would still be too compact to use in KBS.

Perlite: THE MEDIUM OF CHOICE! Completely Inert, Lightweight, easy to clean, easy to use, wicks water well, holds water well, holds LOTS of air, hard to overwater, doesnt affect system PH or TDS like coir or lava ....I could keep going on.

Conclusion : Perlite or Coir40%/Hydroton60% mix

Was that what you were looking for?

Hope it Helps

SYK

the `ch0wmix` was coc0/hydrot0n. or, when some kbs`ers went to media instead of full kbs... /or to show/pr0ve trees could be done w/ handwater soiless, w/out bell+whistle of an active system...

many in these far-away-galaxy days use c0co/perlyte, now... not many use 100persent perlyte or 100persent pumice....

maybe found or able to find perlyte/pumice mix to be good mix... lots of air space, never too much water, drainage, 100persent reusable, maybe....

other options include

1/4in gravel (@ any scapeland place), aquarium gravel, washed stone, perlyte (works very well)... if no coco, peat moss, if no peat moss, bark mulch... mixed w/ perlyte... or, by itself...

...pumice, like perlyte, is liteweight volcanic rox. pumice has harder composition, does not compact in lower part of container as much as perlyte, heavier than perlyte (less floating)... can be either handwater daily, or automated feed continuous, pulse, etc... @ end of season, 100persent of pumice held in container 100persent reusable... water+nutrients held in crax of rox... full drainage w/ enough water retained for day/more of moisture... 1/16in, or smallest can find, best... regular gravel 1/4in- work, too, just heavier... @ every scapeland-type place...

hope this helps

Last edited: