Rocket Soul

Well-known member

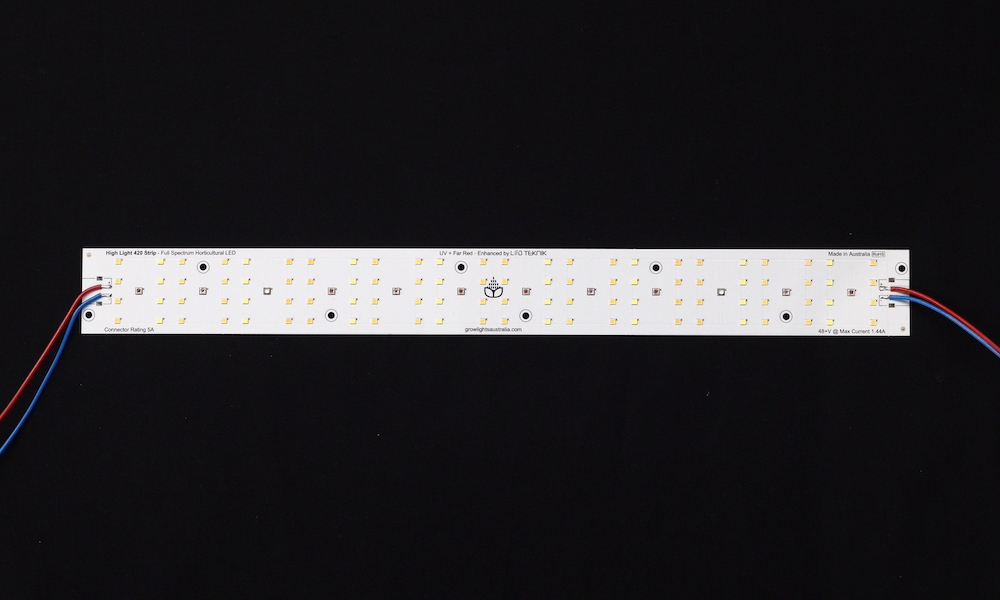

These seems to be a very good deal right now, they where 26 up until very recently.Have not looked into board/strips in a couple of years, but this is first thing I was looking at earlier today. I would need 4 of them for each cab. they rated for up 150w i think, I would have to run them at like half that.

Rspec FR Quantum Board

Ultra High Efficiency LED Boards for DIY. 256pcs Mid power Whites, 12pcs Deep Redhorticulturelightinggroup.com

Ca; what driver/s for 430w? Is that board or system? If MW, how do you dim your drivers? Those nrs (ppf/w and how you calculate ppfd for op) seem somewhat sloppy tbh.

Id tend to agree on a m2 but 3x3 aint a m2

Last edited: