After 2.5 years of use it looks like my vacuum pump oil is quite dirty, or the inside is starting to corrode. Never once changed the oil. I didn't realize the oil got contaminated and needed to be changed before it ran low. Don't be like me, change your pump oil. Because let's be serious, http://www.instructables.com/id/RepairingCleaningUnsiezing-Edwards-RV8-vacuum-pu/?ALLSTEPS doing this doesn't look all that fun.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Extraction Newbie

- Thread starter testymctester

- Start date

After 2.5 years of use it looks like my vacuum pump oil is quite dirty, or the inside is starting to corrode. Never once changed the oil. I didn't realize the oil got contaminated and needed to be changed before it ran low. Don't be like me, change your pump oil. Because let's be serious, http://www.instructables.com/id/RepairingCleaningUnsiezing-Edwards-RV8-vacuum-pu/?ALLSTEPS doing this doesn't look all that fun.

That is a beautiful piece of work! Everyone that has a vacuum pump should at least take a look.

Ok, so everything is finally here! A couple pics below to show the whole setup. The Robinair Cooltech 4 CFM pump (15 micron), Waring single ceramic burner with adjustable thermostat, and vacuum chamber assembly (pot, lid, seal, fittings, gauge, hose, etc.).

Filled up the vacuum pump with oil, plugged it in, and it fired right up. Connected it to the vacuum chamber and it went past 30" on the gauge (who knows how accurate) in about 10 seconds. I played with the valves to adjust the vacuum pressure and get a feel for how it all worked. Closed off the valves at full vacuum and turned the pump off. It's been sitting like that for a few hours now and the gauge hasn't budged. I think I'm in good shape.

The burner is a perfect fit for the chamber, but I haven't tested temps yet with my infrared thermometer to see how stable and even they are. Thanks again for the water and sand bath suggestions. I'll be sure to hook that up if I have problems.

I'm picking up a case of butane using SkyHighLers residue guide tonight and going to do my first blast and purge tomorrow. I'll make sure to get a couple pics along the way and update this thread.

Filled up the vacuum pump with oil, plugged it in, and it fired right up. Connected it to the vacuum chamber and it went past 30" on the gauge (who knows how accurate) in about 10 seconds. I played with the valves to adjust the vacuum pressure and get a feel for how it all worked. Closed off the valves at full vacuum and turned the pump off. It's been sitting like that for a few hours now and the gauge hasn't budged. I think I'm in good shape.

The burner is a perfect fit for the chamber, but I haven't tested temps yet with my infrared thermometer to see how stable and even they are. Thanks again for the water and sand bath suggestions. I'll be sure to hook that up if I have problems.

I'm picking up a case of butane using SkyHighLers residue guide tonight and going to do my first blast and purge tomorrow. I'll make sure to get a couple pics along the way and update this thread.

Attachments

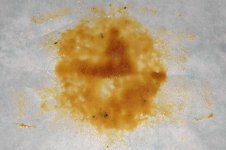

I scraped the pyrex and placed the oil on parchment paper that I placed into the vacuum chamber. Purged a couple times in a hot water bath of approximately 125-130F and the oil measured 118-120F. I don't have much confidence in my thermometer, but that's what was on the display.

Attachments

I thought I had a very stable and thin transparent film after purging 3 times for 10-15 minutes at 118-120F, but it seems to be waxing up a bit now. I did the extraction and purge on Saturday. Today is Wednesday and it is being stored at room temperature.

Not sure if the product is not completely purged or if it needs to be winterized to clean up further. This stuff is insanely potent, but hits my lungs REALLY HARD with a little bit of a smoky taste at the end of a dab. I have to take smaller dabs than normal or I will cough for a while.

I definitely had some contaminants (weed particles) get in the product. As seen in the previous pics. Need to tighten up the technique a bit.

I've been really pressed for time, so I didn't get to document this run as well as I would have like. Thankfully, I just finished another harvest and have plenty of material to run again. More extractions to follow...

Not sure if the product is not completely purged or if it needs to be winterized to clean up further. This stuff is insanely potent, but hits my lungs REALLY HARD with a little bit of a smoky taste at the end of a dab. I have to take smaller dabs than normal or I will cough for a while.

I definitely had some contaminants (weed particles) get in the product. As seen in the previous pics. Need to tighten up the technique a bit.

I've been really pressed for time, so I didn't get to document this run as well as I would have like. Thankfully, I just finished another harvest and have plenty of material to run again. More extractions to follow...

Round 2

Round 2

I made another batch this weekend and got different results. I'm trying to understand what difference in technique contributed to the change in product. The end product this time is nothing but pure flavor and potency with no harshness on the lungs. This product is a light yellow dry crumble while my first run was an amber transparent shatter that waxed up over the course of a week at room temp.

A couple factors I can think of...

- used frozen material the first batch, but did not freeze the material this time

- was a little unsure of temps in the vacuum chamber on the first run, so I ended up breaking the vacuum and taking the lid off multiple times to check things out. I just did one single purge at 120F for 10 minutes and then turned the heat off and left the vacuum on for another 20 minutes this time

I'll post up a picture of the product later this week or weekend when I can, but wanted to ask if anybody could shed some light on what might have caused the different results in the meantime.

Round 2

I made another batch this weekend and got different results. I'm trying to understand what difference in technique contributed to the change in product. The end product this time is nothing but pure flavor and potency with no harshness on the lungs. This product is a light yellow dry crumble while my first run was an amber transparent shatter that waxed up over the course of a week at room temp.

A couple factors I can think of...

- used frozen material the first batch, but did not freeze the material this time

- was a little unsure of temps in the vacuum chamber on the first run, so I ended up breaking the vacuum and taking the lid off multiple times to check things out. I just did one single purge at 120F for 10 minutes and then turned the heat off and left the vacuum on for another 20 minutes this time

I'll post up a picture of the product later this week or weekend when I can, but wanted to ask if anybody could shed some light on what might have caused the different results in the meantime.

IMO the most stable shatter with the best flavor is purged around 90-100f untill no reaction. But that takes days and is not practical for small runs.

I agree with nakadash, you are probably not purging long enough. If I were you I would set my griddle to hold the oil at a steady temperature around 115f and just purge overnight or until no reaction occurs.

I agree with nakadash, you are probably not purging long enough. If I were you I would set my griddle to hold the oil at a steady temperature around 115f and just purge overnight or until no reaction occurs.

Awesome. Thank you! I will try an overnight purge next time to compare the results. It seems this latest round is "cleaner" with a 30 minute purge around 120F. I cannot detect any signs of solvent in the end product.

Do you think it is very likely that this concentrate is completely purged? Or better yet, what is the average time I should expect to purge at 120F to have a product free of residual solvent?

Thanks again for all the help. This forum is great.

Do you think it is very likely that this concentrate is completely purged? Or better yet, what is the average time I should expect to purge at 120F to have a product free of residual solvent?

Thanks again for all the help. This forum is great.

710Chef

Member

I've always read NOT to use frozen plant matter that extractions are better done with room temp nugs since your not trying to break off the heads like when doing a CWE. I've also heard it can cause the tube to become clogged and could seriously injured you!! Be careful and good luck. Also you should by a temperature laser gun there a lifesaver didn't see that in to ur list of tools

I've always read NOT to use frozen plant matter that extractions are better done with room temp nugs since your not trying to break off the heads like when doing a CWE. I've also heard it can cause the tube to become clogged and could seriously injured you!! Be careful and good luck. Also you should by a temperature laser gun there a lifesaver didn't see that in to ur list of tools

Theories and opinions abound! Not sure there are hard and fast rules, but I've personally found that if you freeze fresh buds and pack them in a thermos so they aren't exposed to the moisture in the air, and then freeze them to -18C/0F, ice won't form on the trichomes and they extract very well.

Learned that from Jump 117 here at IC Mag at https://www.icmag.com/ic/showthread.php?t=168388

Because they are at the original monoterpene levels, you extract more, which is also concentrated along with the diterpene cannabinoids, leaving you with an explosively aromatic extract.

If you jar it up afterwards, and take a sniff every time you open the jar, you will see the difference between it and oil extracted drier, after many of the monoterpenes had already evaporated away with the water.

Know what a drying room smells like? The reason why is that the air is full of monoterpene molecules.

That said, you do have to freeze it to make it work and because there is so much bulk with the water still present, yield is low as a percent of weight, meaning you have to process more material to get the same weight of oil.

It is less work and requires less experience to get a gorgeous museum quality extract using material below 10% moisture content, but the aromatics are highly depleted at that level of dessication, because the monoterpenes are high vapor pressure molecules like alcohols, ethers, keytones, aldehydes, etc, which fill rooms with their odors, far below their boiling points, and are the first things to leave.