What are you guys using for cheap frames and heat sinks for led strip style lights like the bridgelux EB series? I’ve got some EB at a inch width and some kingbrite style that are 2inch in width two strips in one. The last time I built my EB light I used aluminum flat bar that I ordered from the internet and chopped down to size for each strip. The two inch wide flatbar is expensive. I looked at heatsinks from heatsinkusa.com and dam $$. I was wanting to build a decent frame and have each strip on a heatsink to help make them last longer.

-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

cheap heat sinks for led strips?

- Thread starter easytoker

- Start date

Its hard to know for sure I'm not an electrician. Can you give some more details or post a photo? Someone will come around and help you.

vladimir882

Member

get a cpu heatsink and DIY with that. cheap and efficient

You could use aluminum U channel - available at Home Despot etc in 8' lengths. Buy 1/2" and cut and bolt/glue pieces together to get your 2" and to increase surface area for heat sinking.

acespicoli

Well-known member

All Heatsinks

Affordable LED Lighting for Growers and Makers. Build your own high quality LED lights using name brand parts at an affordable price. Minimal knowledge required.

They are very responsive to emailed questions

Not my photos these are from the tank light builder forum some tech nerds there for sure

Be sure to click the see more link in the post!!!

Bluefish controller always wanted one of those to mimic the strain im growing native climate perfectly

What driver and how many EB do you wish to run ?

I did a cob build and the hardest part is a quality frame and heat sink bars try the 4x4 canopy with the flat bars

Think you will be happy with the modular build and quality you can stack that fame light or heavy with multiple bars id think but id email the guys over at rapid led and see what they recommend for the tank light builder guys, prob what were looking at above?

Last edited:

acespicoli

Well-known member

Solar radiation in Kingston (Jamaica)

Forecast of solar radiation for 15 days in Kingston. Information on the energy that sunlight will generate, useful for systems that take advantage of this energy, such as the solar panels in your home.

BLUEFISH Aquarium LED Controller

Control your aquarium lighting from your phone or tablet! Simulate weather, sunrise/sunset, moon phases and more!

Solar irradiance - Wikipedia

Solar irradiance is often integrated over a given time period in order to report the radiant energy emitted into the surrounding environment (joule per square metre, J/m2) during that time period. This integrated solar irradiance is called solar irradiation, solar exposure, solar insolation, or insolation.

Irradiance may be measured in space or at the Earth's surface after atmospheric absorption and scattering. Irradiance in space is a function of distance from the Sun, the solar cycle, and cross-cycle changes.[2] Irradiance on the Earth's surface additionally depends on the tilt of the measuring surface, the height of the Sun above the horizon, and atmospheric conditions.[3] Solar irradiance affects plant metabolism and animal behavior.[4]

The study and measurement of solar irradiance have several important applications, including the prediction of energy generation from solar power plants, the heating and cooling loads of buildings, climate modeling and weather forecasting, passive daytime radiative cooling applications, and space travel.

Common questions I ask myself is, how much light do I need to make the plant perform to the best of its ability? My garden outside looks like it struggles at full sun, but thrives on cloudy days.

Does my dimmable LED need to run full power all day ?

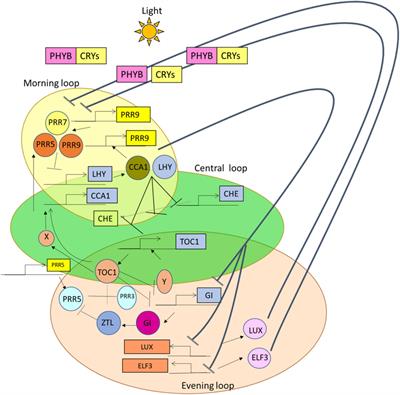

Frontiers | Role of Circadian Rhythms in Major Plant Metabolic and Signaling Pathways

Plants require an endogenous regulatory network and mechanism to cope with diurnal environmental changes and compensate for their sessile nature. Plants use ...

Figure 1. A simplified representation of the suppression of genes having the proteins and photoreceptors present during the functioning of 24 h circadian rhythm. In the presence of light, these photoreceptors Cryptochromes (CRYs) and Phytochrome B (PHY B), which are represented in yellow and pink squares, help in the functioning of genes and proteins; along with the formation of two different negative loops. That is, these morning loop genes [CIRCADIAN CLOCK ASSOCIATED 1 (CCA1) or LATE ELONGATED HYPOCOTYL (LHY)] combine with Pseudo-Response Regulators (PRR7 or PRR9) and suppress the action of CCA1 or LHY (represented with black lines with arrows). On the other hand, TIMING OF CAB EXPRESSION (TOC1) combines with GI, which then leads to the activation of the TOC1 gene. ZEITLUPE (ZTL) is activated with the help of GI, and then GI itself combines with ZTL and suppresses the function of TOC1 (indicated with the black lines along with arrows).

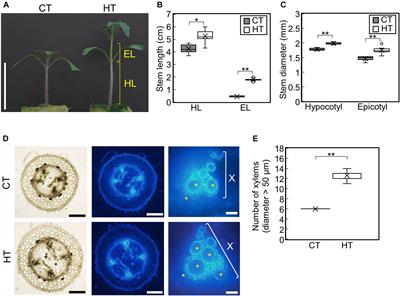

Frontiers | Difference Between Day and Night Temperatures Affects Stem Elongation in Tomato (Solanum lycopersicum) Seedlings via Regulation of Gibberellin and Auxin Synthesis

Temperature is a critical environmental factor governing plant growth and development. The difference between day temperature (DT) and night temperature (NT)...

Our Napa Cabernet Vintage Chart Ratings

Overall vintage ratings for California Cabernet Sauvignon and blends, including the best years for Napa Cabs, and the ideal time to drink the wines.

Top-scoring wines (click for full tasting note):

- Schrader Cellars Cabernet Sauvignon Napa Valley CCS Beckstoffer To Kalon Vineyard

- Colgin Cariad Napa Valley

- Colgin IX Estate Napa Valley

Is cannabis a fruit or a flower ?

Last edited:

Corpselover Fat

Active member

You could use aluminum U channel - available at Home Despot etc in 8' lengths. Buy 1/2" and cut and bolt/glue pieces together to get your 2" and to increase surface area for heat sinking.

Yeah. Or buy aluminium sheet and use that.

Ca++

Well-known member

My cheap option is also U channel. Though China pricing for something better isn't high.

Don't be tempted to polish them, as they won't work as well. Likewise, black is a much better radiator, but paint is adding insulation. Just as it comes is technically acceptable.

If you want to bond two thinner ones, some heatsink plaster is useful. It's somewhere between paste and epoxy. I have little cobs stuck in place with it, so between some U channel it's alright. Not staying wet like paste, or expensive like epoxy.

Obviously coppers thermal conductivity is great for pulling the heat from the individual LEDs hot spot quickly. There is an option to use a thin copper sheet to get that pull and spread going, in a composite design with an alloy backing. Some CPU blocks can be seen using this idea. Where the CPU contact area is copper, which is implanted into a larger alloy block. I have my cobs plastered to round copper disks, that are plastered to alloy heatsinks. As the contact area increases, the thermal conductivity of the material matters less. In your case, a thin copper sheet could be used to get the heat from the package, and transfer it to the alloy channel, which is the designs physical strength.

It could look quite good. Kinda steam punk.

Don't be tempted to polish them, as they won't work as well. Likewise, black is a much better radiator, but paint is adding insulation. Just as it comes is technically acceptable.

If you want to bond two thinner ones, some heatsink plaster is useful. It's somewhere between paste and epoxy. I have little cobs stuck in place with it, so between some U channel it's alright. Not staying wet like paste, or expensive like epoxy.

Obviously coppers thermal conductivity is great for pulling the heat from the individual LEDs hot spot quickly. There is an option to use a thin copper sheet to get that pull and spread going, in a composite design with an alloy backing. Some CPU blocks can be seen using this idea. Where the CPU contact area is copper, which is implanted into a larger alloy block. I have my cobs plastered to round copper disks, that are plastered to alloy heatsinks. As the contact area increases, the thermal conductivity of the material matters less. In your case, a thin copper sheet could be used to get the heat from the package, and transfer it to the alloy channel, which is the designs physical strength.

It could look quite good. Kinda steam punk.

Here's my old light..I used aluminum flat bar that I ordered from the internet and it was cheap..now it's expensive I guess from covid or whatever. It's the same flat bar for the frame and sinks. I think it cost me $30 dollars to built it. looks like now with what I need I'm looking at $100 minimum.

Attachments

Most of the stuff I buy for things like this is from Mcmaster Carr. The more specific you are in what your looking for helps with pricing. Always look at multiple sources before you buy.

smirnoff420

Active member

U-profiles are the best option when it shouldn't be too pricey.

I think at some point it doesn't make sense buying expensive heatsinks, you can rather get more stripes for the money.

I think at some point it doesn't make sense buying expensive heatsinks, you can rather get more stripes for the money.

Dont underestimate the need for proper heatsinks and thermal interface materials. More strips do not make sense if you cannot cool the ones you have. Always use proper materials for the job...you wont regret it. Skimping out now means replacing stuff at the worst time...like 4 weeks into a grow. I have NEVER regretted building something right the first time. I have however regretted going cheap.

peace, negative.

peace, negative.