I don't know about ya'll, but I have been watching CO2 Super Critical Fluid (SFE) with interest and have wanted to sample some cannabis essential oils extracted by that method, but the cost of conventional SFE equipment, is outside the range of most of our finances.

For the rest of ya'll just learning of the process, let's quickly examine what SFE is, by looking at what Wikipedia has to say about it, followed by us'n kicking off a project to develop a small affordable DIY CO2 extractor, that more of us can afford and build:

Supercritical carbon dioxide

From Wikipedia, the free encyclopedia

Carbon dioxide pressure-temperature phase diagram

Supercritical carbon dioxideis a fluid state of carbon dioxide where it is held at or above its critical temperature and critical pressure.

Carbon dioxide usually behaves as a gas in air at standard temperature and pressure (STP), or as a solid called dry ice when frozen. If the temperature and pressure are both increased from STP to be at or above the critical point for carbon dioxide, it can adopt properties midway between a gas and a liquid. More specifically, it behaves as a supercritical fluid above its critical temperature (31.1 °C) and critical pressure (72.9 atm/7.39 MPa), expanding to fill its container like a gas but with a density like that of a liquid.

Supercritical CO2 is becoming an important commercial and industrial solvent due to its role in chemical extraction in addition to its low toxicity and environmental impact. The relatively low temperature of the process and the stability of CO2 also allows most compounds to be extracted with little damage or denaturing. In addition, the solubility of many extracted compounds in CO2 vary with pressure,[1]permitting selective extractions.

Soooo, in us'n layman's terms, we use plain old CO2, that we have gotten hotter than 31.1C/87.98F, while under at least 1086 pounds per square inch pressure.

In that state, the CO2 becomes a super solvent, which has higher penetration power, and can be fine tuned to focus in on specific constitutes, by varying the pressure, temperature, and by the use of co-solvents like ethanol or hexane.

Fair enough, and easy enough to accomplish several ways that immediately come to mind and ah'm hoping some of ya'll experienced SFE brothers and sisters will jump in as this project progresses, and add your two cents!

Traditionally a high pressure intensifier pump is used to achieve the required pressures. They use two different sized pistons on opposite ends of the same shaft. If they put hydraulic pressure on the larger piston, the force it generates is applied against a much smaller piston area on the other end. The difference in surface area's of the two pistons is how much more pressure the smaller piston will generate. It there is 60 times less area, it will produce 60 times more pressure.

Cryo-pumping also works. You start with liquid CO2 or dry ice and heat it in an enclosed space. Gas expansion takes care of all the rest!

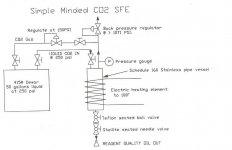

My first conceptual of a system that was semi affordable, was a simple minded system using liquid CO2 and heat to run it at about 1500 PSI. That eliminated the pumps normally used and by using a liquid Dewar with a dip tube, with both a gas head and a liquid tap, the need for any liquid pumps is eliminated as well.

It is designed to use readily available Schedule 160 austenitic stainless pipe and its largest component is small enough to fit in my 7" X 36" lathe. My original plan was to use an existing hydraulic cylinder for my vessel, but alas, carbon steel embrittles excessively at cryogenic temperatures.

My design calls for achieving pressure by simply heating the pipe with available pipe band heaters.

Pressure was controlled using a conventional, though expensive back pressure regulator. Please note the attached conceptual, which reflects my thinking four to five years ago:

I put the project on the back burner after reading the SFE CO2 patents for extracting cannabis, and noting that CO2 isn't a very aggressive solvent and the patented processes used significant fluid exchange rates, as well as relatively long spans of time.

To compound that, reports from those testing SFE CO2 extractions reported poor taste and effects, so I put CO2 extraction on the back burner to just watch for awhile.

Within the last couple of years several folks have done some interesting work starting with dry ice. The first that I noted was able to maintain high enough pressure in a test tube to keep dry ice from sublimating as it warmed, so as to extract some Limonene from an orange peel.

That led me to question whether super critical pressures were required to extract the essential oils from cannabis that we typically extract with other solvents, and further experiments by others on this forum and others, suggests that it is not. Some even report better results at subcritical pressures, especially with the use of co-solvents.

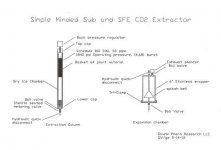

Sub critical extraction presents an interesting twist from a simplicity standpoint, so of course my simple mind immediately envisioned replacing the test tube with a pressure vessel containing dry ice in the bottom, and a basket of material suspended above it. Screw down lid and bring it up to temperature with a pipe clamp heater for pressure.

Flooding is achieved by simply turning it upside down to soak the material and right side up to drain. That step could be repeated back and forth, to soak the material and keep the boundary layers diminished. On setting it upright the final time, we could bleed off the liquid into an expansion chamber and then to atmosphere, leaving behind the oil.

I have decided to build a 2″ X 24″ prototype, and have acquired two resources on this project that emboldens me. One is the offer from a dear old friend, to allow me the use of his pressure and vacuum equipment manufacturing facilities for giggles and old times sake.

The other is an serendipitous agreement with another old friend, who owns a cryogenic equipment manufacturing plant back east and is familiar with SFE.

We have a mutual engineering support agreement in effect, in exchange for my support on one of their projects with a former aerospace customer of mine, who is now their customer as well.

For my support interfacing their equipment with my customer's equipment of my own design and manufacture before retirement, they will support me in developing a simple minded DIY SFE system, that hopefully more of us’ns can afford to build, or have built.

So here is my first simple minded conceptual using liquid and my latest starting with dry ice, but you will have to watch this space for the latest using dry ice.

After promising someone that I would publish yesterday, and after working all day on the drawing, my 2002 32 bit Auto Cad program in XP Pro virtual mode, is not able to access my printer on my 64 bit processor, and I’m not smart enough to figure it out.

I will add that drawing after I find a computer hero or heroine, but the way my conceptual works, is the bottom of the Schedule 160 316L pipe cylinder is filled with dry ice , on top of which sits a wire basket of plant material. Clamp on band heaters turn the dry ice to liquid, which is circulated and soaked through the material by simply turning the cylinder upside down.

After flipping it about a few times, over an extended soak, the vessel is set upright and attached to the lower expansion chamber via a hydraulic quick disconnect. The liquid is bled off, decompressed, and the oil collected from the decompression vessel via the bottom drain valve, as well as via the detachable bottom.

This was written especially for ICMag from data taken from:

http://skunkpharmresearch.com/affordable-diy-co2-extraction/

For the rest of ya'll just learning of the process, let's quickly examine what SFE is, by looking at what Wikipedia has to say about it, followed by us'n kicking off a project to develop a small affordable DIY CO2 extractor, that more of us can afford and build:

Supercritical carbon dioxide

From Wikipedia, the free encyclopedia

Carbon dioxide pressure-temperature phase diagram

Supercritical carbon dioxideis a fluid state of carbon dioxide where it is held at or above its critical temperature and critical pressure.

Carbon dioxide usually behaves as a gas in air at standard temperature and pressure (STP), or as a solid called dry ice when frozen. If the temperature and pressure are both increased from STP to be at or above the critical point for carbon dioxide, it can adopt properties midway between a gas and a liquid. More specifically, it behaves as a supercritical fluid above its critical temperature (31.1 °C) and critical pressure (72.9 atm/7.39 MPa), expanding to fill its container like a gas but with a density like that of a liquid.

Supercritical CO2 is becoming an important commercial and industrial solvent due to its role in chemical extraction in addition to its low toxicity and environmental impact. The relatively low temperature of the process and the stability of CO2 also allows most compounds to be extracted with little damage or denaturing. In addition, the solubility of many extracted compounds in CO2 vary with pressure,[1]permitting selective extractions.

Soooo, in us'n layman's terms, we use plain old CO2, that we have gotten hotter than 31.1C/87.98F, while under at least 1086 pounds per square inch pressure.

In that state, the CO2 becomes a super solvent, which has higher penetration power, and can be fine tuned to focus in on specific constitutes, by varying the pressure, temperature, and by the use of co-solvents like ethanol or hexane.

Fair enough, and easy enough to accomplish several ways that immediately come to mind and ah'm hoping some of ya'll experienced SFE brothers and sisters will jump in as this project progresses, and add your two cents!

Traditionally a high pressure intensifier pump is used to achieve the required pressures. They use two different sized pistons on opposite ends of the same shaft. If they put hydraulic pressure on the larger piston, the force it generates is applied against a much smaller piston area on the other end. The difference in surface area's of the two pistons is how much more pressure the smaller piston will generate. It there is 60 times less area, it will produce 60 times more pressure.

Cryo-pumping also works. You start with liquid CO2 or dry ice and heat it in an enclosed space. Gas expansion takes care of all the rest!

My first conceptual of a system that was semi affordable, was a simple minded system using liquid CO2 and heat to run it at about 1500 PSI. That eliminated the pumps normally used and by using a liquid Dewar with a dip tube, with both a gas head and a liquid tap, the need for any liquid pumps is eliminated as well.

It is designed to use readily available Schedule 160 austenitic stainless pipe and its largest component is small enough to fit in my 7" X 36" lathe. My original plan was to use an existing hydraulic cylinder for my vessel, but alas, carbon steel embrittles excessively at cryogenic temperatures.

My design calls for achieving pressure by simply heating the pipe with available pipe band heaters.

Pressure was controlled using a conventional, though expensive back pressure regulator. Please note the attached conceptual, which reflects my thinking four to five years ago:

I put the project on the back burner after reading the SFE CO2 patents for extracting cannabis, and noting that CO2 isn't a very aggressive solvent and the patented processes used significant fluid exchange rates, as well as relatively long spans of time.

To compound that, reports from those testing SFE CO2 extractions reported poor taste and effects, so I put CO2 extraction on the back burner to just watch for awhile.

Within the last couple of years several folks have done some interesting work starting with dry ice. The first that I noted was able to maintain high enough pressure in a test tube to keep dry ice from sublimating as it warmed, so as to extract some Limonene from an orange peel.

That led me to question whether super critical pressures were required to extract the essential oils from cannabis that we typically extract with other solvents, and further experiments by others on this forum and others, suggests that it is not. Some even report better results at subcritical pressures, especially with the use of co-solvents.

Sub critical extraction presents an interesting twist from a simplicity standpoint, so of course my simple mind immediately envisioned replacing the test tube with a pressure vessel containing dry ice in the bottom, and a basket of material suspended above it. Screw down lid and bring it up to temperature with a pipe clamp heater for pressure.

Flooding is achieved by simply turning it upside down to soak the material and right side up to drain. That step could be repeated back and forth, to soak the material and keep the boundary layers diminished. On setting it upright the final time, we could bleed off the liquid into an expansion chamber and then to atmosphere, leaving behind the oil.

I have decided to build a 2″ X 24″ prototype, and have acquired two resources on this project that emboldens me. One is the offer from a dear old friend, to allow me the use of his pressure and vacuum equipment manufacturing facilities for giggles and old times sake.

The other is an serendipitous agreement with another old friend, who owns a cryogenic equipment manufacturing plant back east and is familiar with SFE.

We have a mutual engineering support agreement in effect, in exchange for my support on one of their projects with a former aerospace customer of mine, who is now their customer as well.

For my support interfacing their equipment with my customer's equipment of my own design and manufacture before retirement, they will support me in developing a simple minded DIY SFE system, that hopefully more of us’ns can afford to build, or have built.

So here is my first simple minded conceptual using liquid and my latest starting with dry ice, but you will have to watch this space for the latest using dry ice.

After promising someone that I would publish yesterday, and after working all day on the drawing, my 2002 32 bit Auto Cad program in XP Pro virtual mode, is not able to access my printer on my 64 bit processor, and I’m not smart enough to figure it out.

I will add that drawing after I find a computer hero or heroine, but the way my conceptual works, is the bottom of the Schedule 160 316L pipe cylinder is filled with dry ice , on top of which sits a wire basket of plant material. Clamp on band heaters turn the dry ice to liquid, which is circulated and soaked through the material by simply turning the cylinder upside down.

After flipping it about a few times, over an extended soak, the vessel is set upright and attached to the lower expansion chamber via a hydraulic quick disconnect. The liquid is bled off, decompressed, and the oil collected from the decompression vessel via the bottom drain valve, as well as via the detachable bottom.

This was written especially for ICMag from data taken from:

http://skunkpharmresearch.com/affordable-diy-co2-extraction/