-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

build / first run of the MKIIIa closed loop butane

- Thread starter Vegan

- Start date

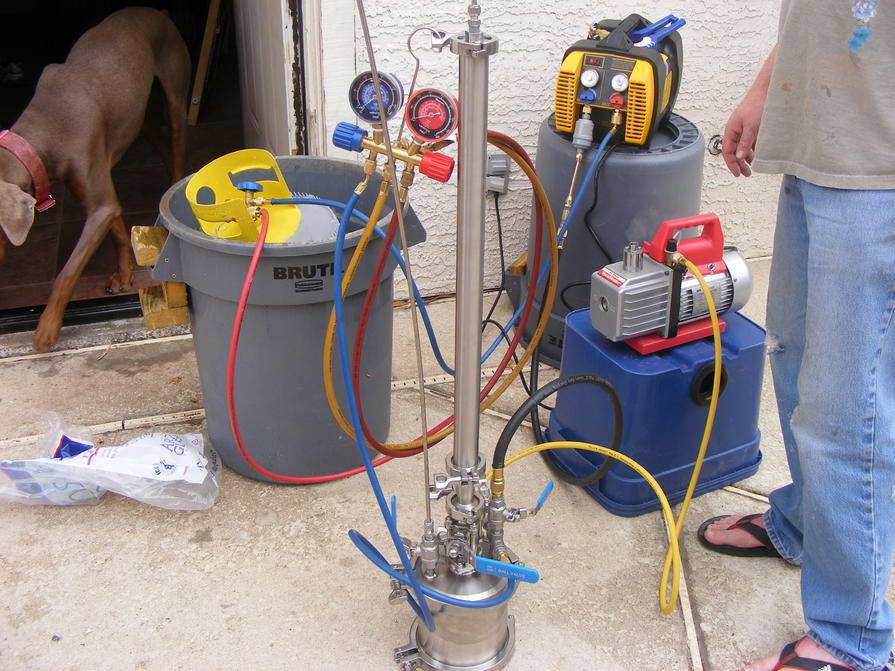

So basically let's get an idea of crap needed for assembly. Some good spanner aka wrenches for all the different fittings. Some Teflon tape for all the screw in fittings. Gotta be carefully when wrapping this stuff it very easily gets folded over the edges which could translate into contaminants in your system.. More on that later. As far as necessity items , I wouldn't even consider running this system without a apion recovery pump so that's definitely a done deal

well ok then,,

here is example of all these little fittings that I was referring to .. sorry for the bad pic

all these blue valves are high quality locking gates

nothing can be accidentally bumped and blow a run

the Appion is a brand new unit hopefully with the filter on there we will get a decent time out of her before she needs a rebuild. anyhoo by then I would think a newer better quieter unit will be better

here is example of all these little fittings that I was referring to .. sorry for the bad pic

all these blue valves are high quality locking gates

nothing can be accidentally bumped and blow a run

the Appion is a brand new unit hopefully with the filter on there we will get a decent time out of her before she needs a rebuild. anyhoo by then I would think a newer better quieter unit will be better

Last edited:

Careful with that copper connection to the filter drier. I had one and because the appion shakes so much it cracked that fitting.

you make an excellent point , that copper line set up is quite flimsy the copper tube bends easily , that shaking can also cause the fitting to loosen up, putting that on a check list

What is the copper thang hanging from the filter drier for?

I know its henky but that's all the minds could come up with to adapt the filter drier line to the collection pot,, it was either this or wait 2-3 weeks for the correct adapter( from what I was told) definitely not permanent

the stainless steel tube was a bitch to work with and these compression fittings are no joke ,, but by the end it was all assembled and ready for a nice vacuum and pressure test.

Vegan,

SS line from top of terp should go to valve on dip tub not the tee, looks like its going to recovery port of tee in last pic.

you make a good point lets take a look at each of those

dip tube vavle on the left and recovery port on the right

all right so lets get down to it ,,first lets check for a vacuum and no leaks

so we turn on the vacuum pump close the recovery valve and open the rest

crap all kinds of leaks ..go back and tighten all fitting down some more

a bit more aggressive on the torque on em ..

ok tighter now ,,, well see if that's enough..

vep holding a vacuum now,,

so we turn on the vacuum pump close the recovery valve and open the rest

crap all kinds of leaks ..go back and tighten all fitting down some more

a bit more aggressive on the torque on em ..

ok tighter now ,,, well see if that's enough..

vep holding a vacuum now,,

ok pressure tested the system this time and again we found some leaks.. got the guage up to and over 100psi and got just a bit of a leak at the top compression fitting ,, again tightened the top union some more ,, really got it on there tight now

all is well and its time to take out our NAPA can tapper .

. more on that later,,tap the cans into the liquid port on the TEE off the pot,,

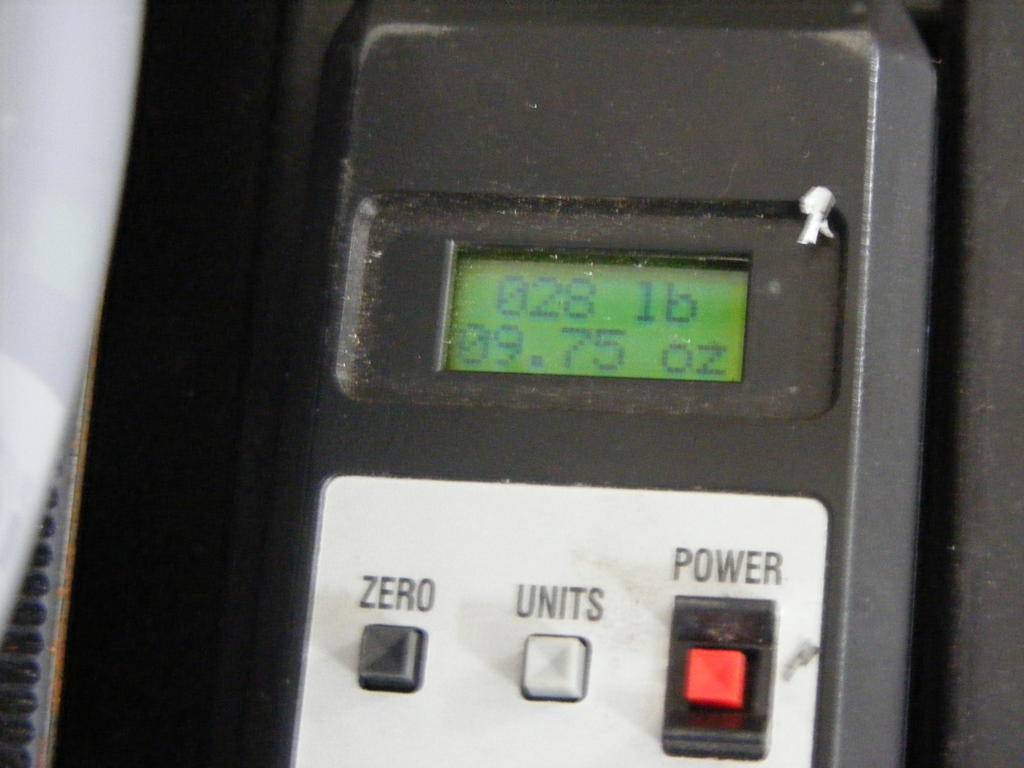

we weighed the empty tank on a digital flat scale

we dumped a couple of cans without turning on the Appion..from there on we started running the recover pump and open the vavle to allow the tane to go to the recovery tank. as the tane empties into the system the cans will acutally start to indent if you leave them on too long, change them out as soon as they are empty and empty and empty and empty ect ect ect

we guesstimated about thirty cans to start with and kept at it ,, pretty time consuming to say the least

ok so all the butane is been recovered through the system and into the tank,,

here is the weight post butane injection we lost a bit of tane during the puncture process,,

ok after a bit of a explosion at the test area we are moving the unit to a different local

all is well and its time to take out our NAPA can tapper .

. more on that later,,tap the cans into the liquid port on the TEE off the pot,,

we weighed the empty tank on a digital flat scale

we dumped a couple of cans without turning on the Appion..from there on we started running the recover pump and open the vavle to allow the tane to go to the recovery tank. as the tane empties into the system the cans will acutally start to indent if you leave them on too long, change them out as soon as they are empty and empty and empty and empty ect ect ect

we guesstimated about thirty cans to start with and kept at it ,, pretty time consuming to say the least

ok so all the butane is been recovered through the system and into the tank,,

here is the weight post butane injection we lost a bit of tane during the puncture process,,

ok after a bit of a explosion at the test area we are moving the unit to a different local

Last edited:

HashoftheTitans

Member

A bit off topic, but if you are going to be blasting around a chlorinated pool you should be sure that you have a proper fire extinguisher present. If you were to have a fire (heaven forbid), your average ABC fire extinguisher would be on hand for put out fires from the initial blast. However, if this type of extinguisher is used around a pool, ammonium compounds (ammonium salts) discharged from the extinguisher can reach the chlorine (oxidizers) and nitrogen trichloride is formed. Nitrogen trichloride, NCI3 is explosive. Just a heads up you should only have a water type extinguisher on hand in a pool area. Besides that, good luck with your first run!

Article Source: http://EzineArticles.com/6107561

Article Source: http://EzineArticles.com/6107561

U

User Name:

what a monster

HashoftheTitans

Member

I was simply pointing out that if flammable solvents are being used, even in a closed loop system, the proper fire extinguisher should be on hand. I noticed a pool in the background (green and probably not chlorinated). A typical ABC extinguisher is not rated and is actually dangerous to discharge in the presence of chlorine. As a former technician in the fire protection industry, I felt that I should inform the OP of the danger as he/she may not be aware. We are working with highly explosive solvents so the last thing we want in the case of an accident is our emergency equipment adding to the problem.

HighStateToke

Member

Can tapping scares the shit out of me. Especially with the recovery pump running, it's almost more nerve racking than open blasting. Very good info HotT

HashoftheTitans

Member

Glad I could actually share some knowledge rather than just leeching off all you pros.

Lono

Member

Glad I could actually share some knowledge rather than just leeching off all you pros.

Awesome suggestion, thank you for that!

I too am curious about the explosion op. What caused it? Everybody okay? your pup alright?

Latest posts

-

-

-

Giardinetto di Totò Indoor... Settimana VIII Fio

- Latest: strain_hunter

-

Latest posts

-

-

-

Giardinetto di Totò Indoor... Settimana VIII Fio

- Latest: strain_hunter

-