MEMED,cheers guys. Hey gholla, are u and squattingbull partners? Just curious. Im surprised yall dont already have this on lock with your situation and all. Its maaaad important to know whats up when your at the level your playing on gholla. Get a clue, or get swallowed up! Word from the wise, no offence.

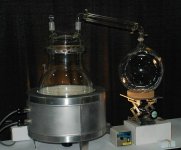

Yeah squattingbull is my roommate and our team biologist/chemistry guru. I do the mechanical stuff. We were both pretty sure about the answer, and had assumed the correct thing, but wanted to know for sure. And you're totally right, which is why we asked before we dropped any cash on a rotovap

We're learning all the time!

GH