-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some concerns ...

- Thread starter JColtrane

- Start date

Fazer1HashTrees

Member

Have you guys seen these pumps: https://us.vwr.com/store/catalog/product.jsp?product_id=4789493

Someone on Skunkpharmresearch is saying to use these heres the actual comment: "USE A WELCH CHEMICAL DUTY FAST DRY PUMP PEOPLE!!!!!!!! MADE IN THE USA. ALL WETTED PARTS ARE MADE TO HANDLE HARSH SOLVENTS. PUMPS ARE ACTUALLY MADE TO BE USED FOR SPECIFIC APPLICATIONS. HOW STUPID ARE YOU TO USE A HVAC PUMP FOR A CHEMICAL/FOOD GRADE APPLICATION? AND PEOPLE ARE ON HERE TALKING ABOUT SAFETY, LOL YOU CRACK ME UP. HOW DO THOSE CHINESE MADE SEALS AND PLASTIC PARTS TASTE IN YOUR CONTAMINATED BHO FROM YOUR GARBAGE PUMP? PROBABLY CAN’T TASTE IT BUT ARE PROBABLY GETTING CANCER AS I TYPE. PEOPLE IN GLASS HOUSES…..GEEZ. I WORK FOR AN INDUSTRIAL RUBBER DISTRIBUTOR AND DEAL WITH PUMPS AND DIFFERENT RUBBERS/POLYMERS ALL DAY EVERY DAY. FOOD GRADE APPLICATIONS AND FABRICATIONS AS WELL. I HAVE A CUSTOM EXTRACTOR I BUILT THAT IS ALL FOOD GRADE AND 100% EXCELLENT RATING FOR ALL SOLVENTS USED. WHY IN THE HELL WOULD I WANT TO RUIN ALL THAT WITH A HVAC PUMP?

I ALSO AM A DISTRIBUTOR FOR DIXON VALVE AND QUICK COUPLING. ONE OF OUR MANY VENDORS. AMERICAN MADE AGAIN. THE QUICK DISCONNECTS I USE ARE FROM THEM AND ARE 316 SS AND HANDLE 10,000 PSI. THEY ARE QUALITY. THEY DO NOT LEAK. YOU BUY SHEET YOU GET SHEET, TOTALLY AGREE WITH THAT. PARKER IS AS WELL BUT I WOULDN’T BUY THEIR IMPORT/CHINESE STUFF FOR THIS APPLICATION.

BALL VALVES IN ANY SYSTEM ARE GARBAGE. DUE TO THE DESIGN WHEN YOU CLOSE THEM YOU GET A SMALL AMOUNT OF RESIDUAL LEFT IN THE VALVE. USE PHARMACEUTICAL GRADE NEEDLE VALVES. HANDLE EITHER 10,000 OR 6,000 PSI. ARE 316 SS AS WELL. MUCH BETTER CONTROL OVER YOUR SYSTEM AS WELL WHEN BLASTING, SOAKING, POWER WASHING, IN LINE DEWAXING /WINTERIZING, AND/OR RECOVERING.

OH YEA MY SYSTEM DOES ALL THOSE FUNCTIONS AS WELL. WAY BETTER THAN ANYTHING I HAVE YET TO LAY EYES ON. ALSO DEIGNED TO EASILY DO ANYWHERE BETWEEN 1/2 OZ TO 50 LBS PER RUN. YES YOU HAVE TO CHANGE OUT A FEW PARTS OBVIOUSLY BUT ONLY THE COLLECTION AND BLAST CHAMBERS.

MY SIGHT GLASS HAS 1/4″ GLASS AND WAS HYDO TESTED FOR HALF AN HOUR AT 150 PSI. I USE NEEDLE VALVES ALL OVER MY SYSTEM. PRETTY MUCH AT EVERY MAIN POINT AND ON EVERY TANK. I COULD EASILY REMOVE IF I WANTED AND NOT LOOSE A THING AS FAR AS FUNCTIONALITY. ALWAYS BEEN LESS WORRIED ABOUT IT COLLAPSING IN INSTEAD OF BLOWING OUT ANYWAY.

ALL WELDS WERE DONE BY A CUSTOM SS FAB SHOP AND POLISHED BACK TO FOOD GRADE LEVELS.

MY COST AND I GET STUFF CHEAP AS A DISTRIBUTOR WITH PUMP………

JUST OVER $6K.

OK ONE LAST THING AND ILL CHILL. IF YOU USE PTFE OR ANY THREAD TAPE, PLEASE STOP. YES THE TAPE ITSELF IS PTFE AKA TEFLON AND HANDLES BUTANE FINE. BUT GUESS WHAT PTFE IS NOT STICKY. THE ADHESIVE USED ON THAT PTFE TAPE IS GUESS WHAT. WAIT FOR IT…………SILICONE. GARBAGE. YOU WILL PROBABLY GET LEAKS EVENTUALLY IF YOU ARE USING THIS. THE ONLY OTHER PTFE TAPE I AM AWARE OF THAT DOES NOT USE SILICONE AS AN ADHESIVE USES ACRYLIC. NOT THE SAME ACRYLIC YOU ARE PROBABLY THINKING OF EITHER. LIKE WHAT LIGHTERS ARE MADE OF. NOT THAT. ALSO I CALLED SEVERAL MANUFACTURES AND IT DOES NOT HAVE A RATING FOR BUTANE. THIS IS BECAUSE NO ON HAS EVER TESTED IT. SO IT MIGHT BE OK. I USE A NON-PTFE FOOD GRADE BUTANE AND SOLVENT SAFE PIPE PASTE. IT’S BLUE. CAN’T REMEMBER THE NAME OF THE COMPANY OFF THE TOP OF MY HEAD.

GOD BLESS

HAPPY BLASTING

THE HOLY GRAIL

BY

CATALYST"

Someone on Skunkpharmresearch is saying to use these heres the actual comment: "USE A WELCH CHEMICAL DUTY FAST DRY PUMP PEOPLE!!!!!!!! MADE IN THE USA. ALL WETTED PARTS ARE MADE TO HANDLE HARSH SOLVENTS. PUMPS ARE ACTUALLY MADE TO BE USED FOR SPECIFIC APPLICATIONS. HOW STUPID ARE YOU TO USE A HVAC PUMP FOR A CHEMICAL/FOOD GRADE APPLICATION? AND PEOPLE ARE ON HERE TALKING ABOUT SAFETY, LOL YOU CRACK ME UP. HOW DO THOSE CHINESE MADE SEALS AND PLASTIC PARTS TASTE IN YOUR CONTAMINATED BHO FROM YOUR GARBAGE PUMP? PROBABLY CAN’T TASTE IT BUT ARE PROBABLY GETTING CANCER AS I TYPE. PEOPLE IN GLASS HOUSES…..GEEZ. I WORK FOR AN INDUSTRIAL RUBBER DISTRIBUTOR AND DEAL WITH PUMPS AND DIFFERENT RUBBERS/POLYMERS ALL DAY EVERY DAY. FOOD GRADE APPLICATIONS AND FABRICATIONS AS WELL. I HAVE A CUSTOM EXTRACTOR I BUILT THAT IS ALL FOOD GRADE AND 100% EXCELLENT RATING FOR ALL SOLVENTS USED. WHY IN THE HELL WOULD I WANT TO RUIN ALL THAT WITH A HVAC PUMP?

I ALSO AM A DISTRIBUTOR FOR DIXON VALVE AND QUICK COUPLING. ONE OF OUR MANY VENDORS. AMERICAN MADE AGAIN. THE QUICK DISCONNECTS I USE ARE FROM THEM AND ARE 316 SS AND HANDLE 10,000 PSI. THEY ARE QUALITY. THEY DO NOT LEAK. YOU BUY SHEET YOU GET SHEET, TOTALLY AGREE WITH THAT. PARKER IS AS WELL BUT I WOULDN’T BUY THEIR IMPORT/CHINESE STUFF FOR THIS APPLICATION.

BALL VALVES IN ANY SYSTEM ARE GARBAGE. DUE TO THE DESIGN WHEN YOU CLOSE THEM YOU GET A SMALL AMOUNT OF RESIDUAL LEFT IN THE VALVE. USE PHARMACEUTICAL GRADE NEEDLE VALVES. HANDLE EITHER 10,000 OR 6,000 PSI. ARE 316 SS AS WELL. MUCH BETTER CONTROL OVER YOUR SYSTEM AS WELL WHEN BLASTING, SOAKING, POWER WASHING, IN LINE DEWAXING /WINTERIZING, AND/OR RECOVERING.

OH YEA MY SYSTEM DOES ALL THOSE FUNCTIONS AS WELL. WAY BETTER THAN ANYTHING I HAVE YET TO LAY EYES ON. ALSO DEIGNED TO EASILY DO ANYWHERE BETWEEN 1/2 OZ TO 50 LBS PER RUN. YES YOU HAVE TO CHANGE OUT A FEW PARTS OBVIOUSLY BUT ONLY THE COLLECTION AND BLAST CHAMBERS.

MY SIGHT GLASS HAS 1/4″ GLASS AND WAS HYDO TESTED FOR HALF AN HOUR AT 150 PSI. I USE NEEDLE VALVES ALL OVER MY SYSTEM. PRETTY MUCH AT EVERY MAIN POINT AND ON EVERY TANK. I COULD EASILY REMOVE IF I WANTED AND NOT LOOSE A THING AS FAR AS FUNCTIONALITY. ALWAYS BEEN LESS WORRIED ABOUT IT COLLAPSING IN INSTEAD OF BLOWING OUT ANYWAY.

ALL WELDS WERE DONE BY A CUSTOM SS FAB SHOP AND POLISHED BACK TO FOOD GRADE LEVELS.

MY COST AND I GET STUFF CHEAP AS A DISTRIBUTOR WITH PUMP………

JUST OVER $6K.

OK ONE LAST THING AND ILL CHILL. IF YOU USE PTFE OR ANY THREAD TAPE, PLEASE STOP. YES THE TAPE ITSELF IS PTFE AKA TEFLON AND HANDLES BUTANE FINE. BUT GUESS WHAT PTFE IS NOT STICKY. THE ADHESIVE USED ON THAT PTFE TAPE IS GUESS WHAT. WAIT FOR IT…………SILICONE. GARBAGE. YOU WILL PROBABLY GET LEAKS EVENTUALLY IF YOU ARE USING THIS. THE ONLY OTHER PTFE TAPE I AM AWARE OF THAT DOES NOT USE SILICONE AS AN ADHESIVE USES ACRYLIC. NOT THE SAME ACRYLIC YOU ARE PROBABLY THINKING OF EITHER. LIKE WHAT LIGHTERS ARE MADE OF. NOT THAT. ALSO I CALLED SEVERAL MANUFACTURES AND IT DOES NOT HAVE A RATING FOR BUTANE. THIS IS BECAUSE NO ON HAS EVER TESTED IT. SO IT MIGHT BE OK. I USE A NON-PTFE FOOD GRADE BUTANE AND SOLVENT SAFE PIPE PASTE. IT’S BLUE. CAN’T REMEMBER THE NAME OF THE COMPANY OFF THE TOP OF MY HEAD.

GOD BLESS

HAPPY BLASTING

THE HOLY GRAIL

BY

CATALYST"

Sounds like a very enraged individual but I will offer my comments.

1) The welch pump is a chemical rated vacuum pump. We used to use them in the lab all the time for vacuum, but it is not the equivalent of a recovery pump.

2) I am glad he uses quality quick-disconnects. I don't use quick disconnects anywhere, so this is of little concern to me.

3) He is arguing against ball valves because a small residual amount gets trapped inside the ball when you close it? Does he not clean his systems out when he is done with them? These ball valves valves are used in sanitary applications in the food industry every day all over the world.

Good for you dude.

Good for you dude.

I am not sure what PTFE tape he is using, but he is obviously using the stuff with the silicone backing adhesive, which is not the right stuff to be using. The MSDS sheet for the PTFE tape I use does not list any silicone, and certainly isnt "sticky" or adhesive backed.

1) The welch pump is a chemical rated vacuum pump. We used to use them in the lab all the time for vacuum, but it is not the equivalent of a recovery pump.

2) I am glad he uses quality quick-disconnects. I don't use quick disconnects anywhere, so this is of little concern to me.

3) He is arguing against ball valves because a small residual amount gets trapped inside the ball when you close it? Does he not clean his systems out when he is done with them? These ball valves valves are used in sanitary applications in the food industry every day all over the world.

OH YEA MY SYSTEM DOES ALL THOSE FUNCTIONS AS WELL. WAY BETTER THAN ANYTHING I HAVE YET TO LAY EYES ON. ALSO DEIGNED TO EASILY DO ANYWHERE BETWEEN 1/2 OZ TO 50 LBS PER RUN. YES YOU HAVE TO CHANGE OUT A FEW PARTS OBVIOUSLY BUT ONLY THE COLLECTION AND BLAST CHAMBERS.

Good for you dude.

MY SIGHT GLASS HAS 1/4″ GLASS AND WAS HYDO TESTED FOR HALF AN HOUR AT 150 PSI. I USE NEEDLE VALVES ALL OVER MY SYSTEM. PRETTY MUCH AT EVERY MAIN POINT AND ON EVERY TANK. I COULD EASILY REMOVE IF I WANTED AND NOT LOOSE A THING AS FAR AS FUNCTIONALITY. ALWAYS BEEN LESS WORRIED ABOUT IT COLLAPSING IN INSTEAD OF BLOWING OUT ANYWAY.

Good for you dude.

OK ONE LAST THING AND ILL CHILL. IF YOU USE PTFE OR ANY THREAD TAPE, PLEASE STOP. YES THE TAPE ITSELF IS PTFE AKA TEFLON AND HANDLES BUTANE FINE. BUT GUESS WHAT PTFE IS NOT STICKY. THE ADHESIVE USED ON THAT PTFE TAPE IS GUESS WHAT. WAIT FOR IT…………SILICONE. GARBAGE. YOU WILL PROBABLY GET LEAKS EVENTUALLY IF YOU ARE USING THIS. THE ONLY OTHER PTFE TAPE I AM AWARE OF THAT DOES NOT USE SILICONE AS AN ADHESIVE USES ACRYLIC. NOT THE SAME ACRYLIC YOU ARE PROBABLY THINKING OF EITHER. LIKE WHAT LIGHTERS ARE MADE OF. NOT THAT. ALSO I CALLED SEVERAL MANUFACTURES AND IT DOES NOT HAVE A RATING FOR BUTANE. THIS IS BECAUSE NO ON HAS EVER TESTED IT. SO IT MIGHT BE OK. I USE A NON-PTFE FOOD GRADE BUTANE AND SOLVENT SAFE PIPE PASTE. IT’S BLUE. CAN’T REMEMBER THE NAME OF THE COMPANY OFF THE TOP OF MY HEAD.

I am not sure what PTFE tape he is using, but he is obviously using the stuff with the silicone backing adhesive, which is not the right stuff to be using. The MSDS sheet for the PTFE tape I use does not list any silicone, and certainly isnt "sticky" or adhesive backed.

Have you guys seen these pumps: https://us.vwr.com/store/catalog/product.jsp?product_id=4789493

Someone on Skunkpharmresearch is saying to use these heres the actual comment: "USE A WELCH CHEMICAL DUTY FAST DRY PUMP PEOPLE!!!!!!!! MADE IN THE USA. ALL WETTED PARTS ARE MADE TO HANDLE HARSH SOLVENTS.

Skunk Pharm Research is currently using a Welch pump on our Cascade TEK R&D oven, not on our recycle units.

We are also looking at Welch pumps in other applications, but as of yet, they are not the great panacea, only a good brand and another valuable tool.

PUMPS ARE ACTUALLY MADE TO BE USED FOR SPECIFIC APPLICATIONS. HOW STUPID ARE YOU TO USE A HVAC PUMP FOR A CHEMICAL/FOOD GRADE APPLICATION?

Depends on the process and whether the product is ever exposed to any of the non food grade parts of the system.

AND PEOPLE ARE ON HERE TALKING ABOUT SAFETY, LOL YOU CRACK ME UP. HOW DO THOSE CHINESE MADE SEALS AND PLASTIC PARTS TASTE IN YOUR CONTAMINATED BHO FROM YOUR GARBAGE PUMP? PROBABLY CAN’T TASTE IT BUT ARE PROBABLY GETTING CANCER AS I TYPE.

You know this how? Have you analyzed any of the seals made out side the good ole US of A?

I can attest to their poor fit, which is why we switched to a US manufacturer, but haven't observed degradation?

PEOPLE IN GLASS HOUSES…..GEEZ. I WORK FOR AN INDUSTRIAL RUBBER DISTRIBUTOR AND DEAL WITH PUMPS AND DIFFERENT RUBBERS/POLYMERS ALL DAY EVERY DAY. FOOD GRADE APPLICATIONS AND FABRICATIONS AS WELL.

Ummmm, OK! Good to know.

I HAVE A CUSTOM EXTRACTOR I BUILT THAT IS ALL FOOD GRADE AND 100% EXCELLENT RATING FOR ALL SOLVENTS USED. WHY IN THE HELL WOULD I WANT TO RUIN ALL THAT WITH A HVAC PUMP?

I ALSO AM A DISTRIBUTOR FOR DIXON VALVE AND QUICK COUPLING. ONE OF OUR MANY VENDORS. AMERICAN MADE AGAIN. THE QUICK DISCONNECTS I USE ARE FROM THEM AND ARE 316 SS AND HANDLE 10,000 PSI. THEY ARE QUALITY. THEY DO NOT LEAK.

Dixon valves are made in China, from Chinese seals. We've used them, but switched to AT, which are made here in the good ole US of A.

Both work well so far, so I would be happy with either.

I've yet to ever see a quick disconnect that never leaked. If you look at the design, you will see that it is easy for something to lodge in the seats and eventually the seats lose resilience.

A listening walk through a factory after hours, will attune you to the propensity of quick disconnects to eventually leak.

YOU BUY SHEET YOU GET SHEET, TOTALLY AGREE WITH THAT. PARKER IS AS WELL BUT I WOULDN’T BUY THEIR IMPORT/CHINESE STUFF FOR THIS APPLICATION.

BALL VALVES IN ANY SYSTEM ARE GARBAGE. DUE TO THE DESIGN WHEN YOU CLOSE THEM YOU GET A SMALL AMOUNT OF RESIDUAL LEFT IN THE VALVE. USE PHARMACEUTICAL GRADE NEEDLE VALVES. HANDLE EITHER 10,000 OR 6,000 PSI. ARE 316 SS AS WELL. MUCH BETTER CONTROL OVER YOUR SYSTEM AS WELL WHEN BLASTING, SOAKING, POWER WASHING, IN LINE DEWAXING /WINTERIZING, AND/OR RECOVERING.

An interesting position! Having worked for a valve manufacturer, I chose 1000# full port ball valves not only for their bubble tight reliability, but for their CV.

Have you looked at the CV of needle valves, which are not full port and considered their opening speed as well.

For the application, a plug valve would be a better application than a needle valve, typically chosen for its superior metering capabilities. Plug valves are also typically a rising stem valve, and slow from crack to full open, plus typically have a lower CV than a full port ball valve.

OH YEA MY SYSTEM DOES ALL THOSE FUNCTIONS AS WELL. WAY BETTER THAN ANYTHING I HAVE YET TO LAY EYES ON. ALSO DEIGNED TO EASILY DO ANYWHERE BETWEEN 1/2 OZ TO 50 LBS PER RUN. YES YOU HAVE TO CHANGE OUT A FEW PARTS OBVIOUSLY BUT ONLY THE COLLECTION AND BLAST CHAMBERS.

Pictures?

MY SIGHT GLASS HAS 1/4″ GLASS AND WAS HYDO TESTED FOR HALF AN HOUR AT 150 PSI.

Hydro tested by whom and at what temperature? I was told the same thing, but have seen on confirming paperwork or ASTME certification, despite pressing.

Two issues to consider, the first is the properties of Borosilicate or glass.

You say glass, which I hope is your typo or understanding error, rather than your physical error, because glass has very poor mechanical properties for this application and most serious folks use Borosilicate (Pyrex).

One issue is the temperature swing, which puts undue stress on both glass and borosilicate, because of uneven expansion.

If you look at the strength curve, it drops off steadily as the temperature drops.

You will also note that the design of the tubular sight glasses, puts the glass in tension when pressure is applied, which is glasses worst possible application.

We've gone to a system that puts a wafer of Borosilicate under column load, which is its best possible application. They are rated at 720 psi at 100F, and are available to 3000 psi.

Where you stick the sight glass also makes a difference, because if it is locked between to valves and full of liquid, you are applying hydraulic expansion loads.

I USE NEEDLE VALVES ALL OVER MY SYSTEM. PRETTY MUCH AT EVERY MAIN POINT AND ON EVERY TANK. I COULD EASILY REMOVE IF I WANTED AND NOT LOOSE A THING AS FAR AS FUNCTIONALITY. ALWAYS BEEN LESS WORRIED ABOUT IT COLLAPSING IN INSTEAD OF BLOWING OUT ANYWAY.

ALL WELDS WERE DONE BY A CUSTOM SS FAB SHOP AND POLISHED BACK TO FOOD GRADE LEVELS.

MY COST AND I GET STUFF CHEAP AS A DISTRIBUTOR WITH PUMP………

JUST OVER $6K.

OK ONE LAST THING AND ILL CHILL. IF YOU USE PTFE OR ANY THREAD TAPE, PLEASE STOP. YES THE TAPE ITSELF IS PTFE AKA TEFLON AND HANDLES BUTANE FINE. BUT GUESS WHAT PTFE IS NOT STICKY. THE ADHESIVE USED ON THAT PTFE TAPE IS GUESS WHAT. WAIT FOR IT…………SILICONE. GARBAGE. YOU WILL PROBABLY GET LEAKS EVENTUALLY IF YOU ARE USING THIS. THE ONLY OTHER PTFE TAPE I AM AWARE OF THAT DOES NOT USE SILICONE AS AN ADHESIVE USES ACRYLIC. NOT THE SAME ACRYLIC YOU ARE PROBABLY THINKING OF EITHER. LIKE WHAT LIGHTERS ARE MADE OF. NOT THAT. ALSO I CALLED SEVERAL MANUFACTURES AND IT DOES NOT HAVE A RATING FOR BUTANE. THIS IS BECAUSE NO ON HAS EVER TESTED IT. SO IT MIGHT BE OK. I USE A NON-PTFE FOOD GRADE BUTANE AND SOLVENT SAFE PIPE PASTE. IT’S BLUE. CAN’T REMEMBER THE NAME OF THE COMPANY OFF THE TOP OF MY HEAD.

Rector Seal maybe?

GOD BLESS

Thanks, already a done deal!

HAPPY BLASTING

THE HOLY GRAIL

BY

CATALYST"

You may not be aware that all caps means that you are shouting down at us, and I doubt that is your intention.

I sense your heart is in the right place, but you appear to have "missunderestimated" some details. I predict if you dig deeper, you will change your mind on some of the above issues.

Fazer1HashTrees

Member

Sorry that was a message from skunkpharmresearch. I should have just posted the part about the pump.

Do you guys know if I can run the CPS TR21 without the heat exchanger with a bhogart extractor? Or should I just go with rg6000? BHOGART said they are making a stainless steel version of the MT69. So I wouldn't be running it without one for long just until they get those in stock.

Do you guys know if I can run the CPS TR21 without the heat exchanger with a bhogart extractor? Or should I just go with rg6000? BHOGART said they are making a stainless steel version of the MT69. So I wouldn't be running it without one for long just until they get those in stock.

I think this question has been answered several times. SURE you COULD do it, but NO its NOT recommended. I don't think the reasons need to be stated again.

I would highly recommend not paying for bhogarts high priced BS, and don't bank on their ETA's. If your that concerned why not just pick up a MT69?

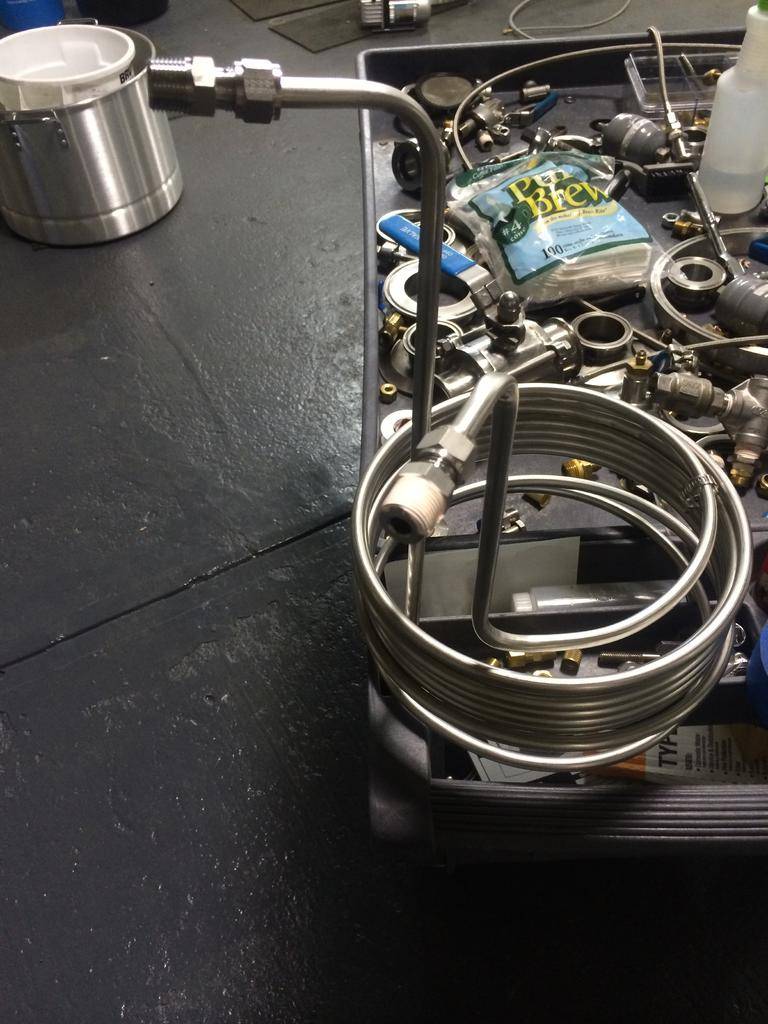

Or as I and others have mentioned save a few bucks by getting a wrench, two compression fittings and a 25' long 3/8" OD stainless immersion chiller from any online brewery supply...

I would highly recommend not paying for bhogarts high priced BS, and don't bank on their ETA's. If your that concerned why not just pick up a MT69?

Or as I and others have mentioned save a few bucks by getting a wrench, two compression fittings and a 25' long 3/8" OD stainless immersion chiller from any online brewery supply...

Sorry that was a message from skunkpharmresearch. I should have just posted the part about the pump.

Do you guys know if I can run the CPS TR21 without the heat exchanger with a bhogart extractor? Or should I just go with rg6000? BHOGART said they are making a stainless steel version of the MT69. So I wouldn't be running it without one for long just until they get those in stock.

Yeah, I looked for it to put things in context, but didn't find it, so just answered the question.

Feel free to post enough of the Skunk Pharm Research stuff for me understand what context the message was offered in.

You can run a CPS TR21 without a heat exchanger, but unlike the Appion and Pro Max, they don't have an internal one, so the gas discharge from them is significantly above the boiling point of butane, and will drive up your tank pressure, as well as slow down your process.

A stainless steel MT-69 would still be undersized, and even less effective, because of the lower heat transfer (K) of stainless steel, vis a vis copper.

The 3/8" stainless coil and fittings pictured by PC are rated above 2000 psi, has far greater heat transfer area, don't plug at low temperatures, and are a far better choice from a performance standpoint.

Best yet, the price isn't artificially inflated because they are readily available from multiple sources serving the brewery market.

analogcricket

Member

anyone try using a haskel?

http://www.haskel.com/StaticFiles/MRContent/StaticFiles/Haskel/en/PDF;s/Refrigerant_Pumps.pdf

or

yellow jacket lte?

http://www.haskel.com/StaticFiles/MRContent/StaticFiles/Haskel/en/PDF;s/Refrigerant_Pumps.pdf

or

yellow jacket lte?

Picking up the compressor for the haskel next week  Very excited!!!

Very excited!!!

Chonkski

Member

I have been losing so much tane at the end of work days from my heat exchanger coil! I have tried everything, from chilling the tank and putting the coil in hot water, to simply holding it upside down for a minute. I'm losing near a quarter pound everytime i disassemble at the end of the day.

Chonski, if you isolate one end of your heat exchanger (the valve on the pump outlet and put it in hot water for a while it should vaporize all the butane in it and push it to the holding tank.

Make sure the water is hot enough to actually vaporize the butane under whatever pressure its at. Check a vapor pressure chart first.

You shouldn't be losing anything from the heat exchanger.

RB

Make sure the water is hot enough to actually vaporize the butane under whatever pressure its at. Check a vapor pressure chart first.

You shouldn't be losing anything from the heat exchanger.

RB

anyone try using a haskel?

http://www.haskel.com/StaticFiles/MRContent/StaticFiles/Haskel/en/PDF;s/Refrigerant_Pumps.pdf

or

yellow jacket lte?

We use the 59025.

GW, we are getting ready to rig up a Haskel 59025 to a 7.5HP 200psi compressor. Do you think we will get decent speeds using this setup. We have a larger compressor we can use but would need to hook up 3 phase at the shop. My partner is an engineer and has come up with a way to expand the current compressors capacity with another tank to keep up with the amount of air the Haskell will eat. Are we wasting our time? Bringing the larger 3phase compressor to our location is an undertaking and hooking it up to three phase is another pain in the ass. Thanks for all your contributions, i'd be back in the extraction stone age if it wasn't for you and all the other contributors on here.

I think your wasting your time. These haskels need a screw compressor, 10hp for each pump. There are major differences between your standard compressor and a screw compressor. I don't think a bigger tank would do anything for output.

How'd you get a haskel that quick? Thought they had 45-60 day lead time?

Your on the right track though, I'd call an electrician and your provider and get a quote on dropping another line, it won't be cheap, but nothing is if done properly.

How'd you get a haskel that quick? Thought they had 45-60 day lead time?

Your on the right track though, I'd call an electrician and your provider and get a quote on dropping another line, it won't be cheap, but nothing is if done properly.

GW, we are getting ready to rig up a Haskel 59025 to a 7.5HP 200psi compressor. Do you think we will get decent speeds using this setup. We have a larger compressor we can use but would need to hook up 3 phase at the shop. My partner is an engineer and has come up with a way to expand the current compressors capacity with another tank to keep up with the amount of air the Haskell will eat. Are we wasting our time? Bringing the larger 3phase compressor to our location is an undertaking and hooking it up to three phase is another pain in the ass. Thanks for all your contributions, i'd be back in the extraction stone age if it wasn't for you and all the other contributors on here.

[url='https://www.icmag.com/ic/attachment.php?attachmentid=285753']

Attachments

GW, we are getting ready to rig up a Haskel 59025 to a 7.5HP 200psi compressor. Do you think we will get decent speeds using this setup. We have a larger compressor we can use but would need to hook up 3 phase at the shop. My partner is an engineer and has come up with a way to expand the current compressors capacity with another tank to keep up with the amount of air the Haskell will eat. Are we wasting our time? Bringing the larger 3phase compressor to our location is an undertaking and hooking it up to three phase is another pain in the ass. Thanks for all your contributions, i'd be back in the extraction stone age if it wasn't for you and all the other contributors on here.

The Haskel is a fixed displacement pump. To run at full speed, the Haskell needs 40 scfm of clean 100 psi air. 20 scfm will run it at exactly half speed.

As long as it is clean and 40 scfm, the Haskel doesn't care where it comes from. You could put ten small compressors with refrigerative driers on a common receiving tank and run the Haskel that way.

I say screw compressor, because that is usually the cheapest way to make that much air continuously, if you install the low unloaded horsepower feature, where the compressor inlet is closed when it reaches pressure, instead of shutting down the motor. That pulls a vacuum inside the compressor, causing it to draw only idling horsepower until the inlet opens again. It also saves the huge locked rotor spikes starting up the large motors each time.

The Haskel is a fixed displacement pump. To run at full speed, the Haskell needs 40 scfm of clean 100 psi air. 20 scfm will run it at exactly half speed.

As long as it is clean and 40 scfm, the Haskel doesn't care where it comes from. You could put ten small compressors with refrigerative driers on a common receiving tank and run the Haskel that way.

I say screw compressor, because that is usually the cheapest way to make that much air continuously, if you install the low unloaded horsepower feature, where the compressor inlet is closed when it reaches pressure, instead of shutting down the motor. That pulls a vacuum inside the compressor, causing it to draw only idling horsepower until the inlet opens again. It also saves the huge locked rotor spikes starting up the large motors each time.

Now I feel much better that you think its possible, my partner seems certain he can rig up the current compressor to run the Haskel at full speed. We agreed that we would use the current setup for the first Haskel and that if things went well, we'd bring the bad boy 15HP Screw compressor from the other warehouse to run the next two Haskels. Very excited to say the least.....

Now I feel much better that you think its possible, my partner seems certain he can rig up the current compressor to run the Haskel at full speed. We agreed that we would use the current setup for the first Haskel and that if things went well, we'd bring the bad boy 15HP Screw compressor from the other warehouse to run the next two Haskels. Very excited to say the least.....

The Haskel doesn't use an inline oiler, so clean dry air is critical. Refrigerative driers are relatively cheap, and a good investment.

The Haskel doesn't use an inline oiler, so clean dry air is critical. Refrigerative driers are relatively cheap, and a good investment.

We've got a refrigerative dryer on order. Is the Haskell running at full speed the fastest way to recover or is it just the safest? How long do you think the recovery time on an MkIV will be on the full speed Haskel with a 1lb or 2.5lb column? Thanks for all the knowledge!