T

TribalSeeds

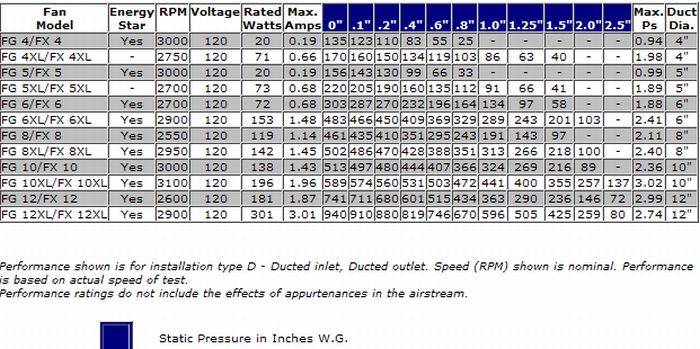

I was talking about the the temp diff between a 6 inch vortex and a 6 inch S&P. Not a 6 vs 8 inline fan.

Yea, I get it... What Im saying is there is no difference if the 6" fan adequately cools a space, more CFM's arent gonna make it any cooler. Doesnt matter if its 6" or 12"