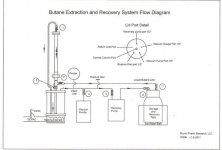

I am impressed with the results QTS demonstrated with his Tamisium extraction and recovery unit, but the sticker shock cuts to the very soul of a cheap bastard like Moi, so I began to think about how one might put together a more affordable system, operating on the same principles of hot and cold.

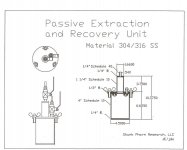

A storage tank can be simply made from a propane torch tank, by changing out the valve assembly. Since I've seen several pictures of that solution on line, I focused instead on the extraction unit itself. I've played with a couple different sizes and designs, but here is a conceptual design for simple one, that holds around an ounce and can be built for under a couple of hundred dollars.

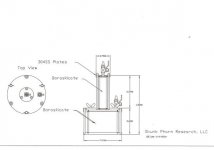

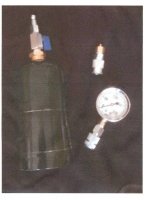

Here is also another larger one, that uses borosilicate column and collection tank, so that you can watch it operate:

I will build the first to prove out the concept, and the glass and stainless unit, if the all stainless one pans out.

A storage tank can be simply made from a propane torch tank, by changing out the valve assembly. Since I've seen several pictures of that solution on line, I focused instead on the extraction unit itself. I've played with a couple different sizes and designs, but here is a conceptual design for simple one, that holds around an ounce and can be built for under a couple of hundred dollars.

Here is also another larger one, that uses borosilicate column and collection tank, so that you can watch it operate:

I will build the first to prove out the concept, and the glass and stainless unit, if the all stainless one pans out.