StrangeVisitor

Member

So here is a well working tested technology effective and 100% DIY. I’m happy to share it, as most of ideas I’ve picked up on the forums and icmag particularly. I wish this humble contribution will help those who desire to grow on their own and get off the nasty dependance. Peace.

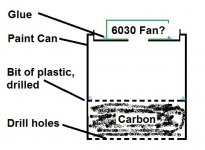

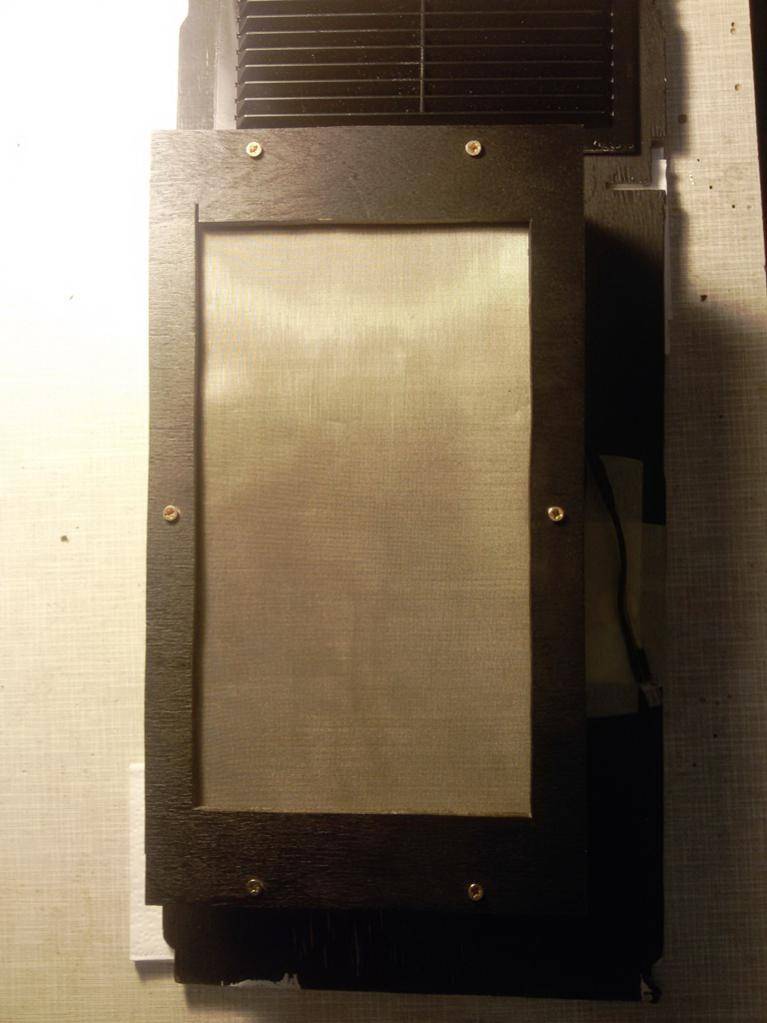

In the photos below you can see the filter inside a growbox (on the right side) and after assembly ready to be put into operation.

The key element of the scrubber is a radial fan (blower, turbine). These types of fans are capable of moving air well enough through a filter (air resistance). The pressure that a radial fan develops is approx. 10 times greater than a comparable axial fan (regular pc fan) does.

The filter contains about 1l (1/4 gal) of charcoal, 34mm (1.3”) thick. That's enough for several cycles with smelly strains.

In the photos below you can see the filter inside a growbox (on the right side) and after assembly ready to be put into operation.

The key element of the scrubber is a radial fan (blower, turbine). These types of fans are capable of moving air well enough through a filter (air resistance). The pressure that a radial fan develops is approx. 10 times greater than a comparable axial fan (regular pc fan) does.

The filter contains about 1l (1/4 gal) of charcoal, 34mm (1.3”) thick. That's enough for several cycles with smelly strains.