Hello all. Been doing a lot of testing with making extracts with ethanol extraction. I pre-process prime cured flower by making dry ice hash using 190 screen bubble bag. I use 2x 5 gallon buckets and shake for 3-4 minutes in first bucket, and then another 3-4 minutes in the 2nd. I then immediately dump the bubble bag material in a tray and remove all dry ice chunks which draw in moisture.

I now have 3 grades of material and place each in a labeled ziplock. The logic of doing this first step is to dry the material further without adding heat, and second to use less ethanol. I often do several pounds in 6-8 ounce runs, and it is basically a closed system that has no reduction in yield. Bubble bag is caked with kief at the very end, but I just place this bag in a traditional ice water bubble bags and get some nice bubble hash for me.

I then use a modified medical transport cooler as a sink with a 10x10x2 slab of dry ice to cool all material to around -40 F. The 10x10 holds 5x 500ml beakers, which is usually is 2x 1st pass kief, 1x 2nd pass kief & 2x bag leftover - all from the same strain. I have a second dry ice storage chest that I use to pre-cool the ethanol to -40 F/-50 F.

I follow many things from Skunk Pharm Research, but my filtering process is a little different since I now have fine kief and pulverized flower material, which takes much longer to filter. After testing 190, I only use 200 proof Extractohol to avoid contaminant pickup, as ethanol is exposed to material for 30-45 minutes total. I pour the -50F ethanol completely over the pre-cooled (20-30 minutes) material in all beakers and let sit for 10-15 minutes stirring a few times.

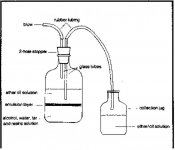

I use a 1000ml buchner funnel with 110mm Whatman #1 filters connected to BVV 1.5 Gallon Cold Trap and 3cfm vacuum pump. I installed a series of ball valves that let me isolate and throttle vaccum. I made what could be called a removable thermal diaper using radiant barrier material and foil tape that completely covers the sides and bottom of buchner funnel with about 3/4" gap around all sides. I then place about 1/2 pound of dry ice pellets around the outside of the funnel and cover it with another thermal lid made from radiant barrier. After cooling for 10-15 minutes, the glass frit and most of funnel is -30F - -40F, and it is ready to go.

I then place a fresh #1 filter and pour a small amount of chilled ethanol over filter and turn on vacuum to prime. I throttle vacuum (between pump and cold trap) so that no liquid is sucked into vacuum line from funnel and then completely pour the contents from 1st pass kief beakers into the filter. The fine kief quickly clogs the filter and requires an increase in vacuum (to about 75%) to maintain a nice steady filter pour. Depending on material - 6 ounces for this example, it takes about 5-7 minutes to filter 500ml from initial beaker soaking. After the material on filter dries out slightly, I will pour another 200-300ml chilled ethanol to maximize extraction.

Now, I pour the ~700ml of filtered ethanol into a clean beaker and set aside. After reattaching funnel to flask, I bring back to near full vacuum and pour the 2nd pass kief solution on top of the 1st pass still in the filter. This takes ~10 minutes to fully filter, after which I add the final 2 beakers of bag material solution. Bag material takes about 10-15 minutes to filter. 2nd pass and bag material stay in same flask. After fully filtering, I add another 200-300ml chilled ethanol to maximize extraction. At this point, the kief/bag material in the funnel is still at -20 - -30F, and depending on amount of starting material, it is a solid 1 1/2"-2" thick above filter pad.

I now have 2 grades of extract laden ethanol, which I can process separately or just add together for full body. The 1st grade is always deep amber, but the 2nd grade does pick up a very small shade of pale green, but after 30-60 minutes at room temperature, or immediately upon heating, all green goes away and a deeper amber than 1st remains. Both are crystal clear with no clouds. I then use a heating and stirring mantle and distillation apparatus to separate ethanol. Once ~85% of ethanol is evaporated, I collect material in small beaker and use 0.22um syringe filters. Solution goes from syringe directly into 120mm glass petri dishes, which have been marked and pre-weighed, and into AI 5-wall vacuum oven. I try to estimate 5-6 grams of shatter per petri dish.

Now, this brings me to the heart of my post. My first few tests using the system above produced the most rock hard shatter that I found nearly impossible to fully purge (at temps below 130). The 200 proof ethanol creates a thick film that bubbles have a very difficult time popping. I did some small tests that took temps of 160 under full vacuum (29.5) to purge. This is obviously not acceptable for creating vapable extracts.

I did the exact same steps above using 190 proof Everclear, and it does pick up a bit more green on 2nd/bag run, but it also picks up a cloudy element and other contaminants - clearly not acceptable either. However, I found that 190 processed material was easy to purge using a temp ramp from 110 to 125 over a few hours. It produced a much runnier extract far from shatter.

So... For my last test, I did my 200 proof process through distillation, but right before the 0.22um step, I poured a small amount of 190 Everclear in the solution. I used 40ml of Everclear for what I estimated would be 40 grams of shatter. 190 is 5% water, so 40 x .05 = 2ml of water added into solution. It turned out that this worked fantastic. It purged easily and created a nice hard taffy shatter.

However, my last batches of fully purged shatter have had little taste when I dab. Great and powerful high, but not much taste. I make both oral meds and vape products, and I have averaged about 25-27% shatter using some high quality flowers from Bodhi strains with this process.

I felt in necessary to better explain my process first, but my questions are the following:

1.) Am I even extracting all the terps, given the temps and fact that 200 proof ethanol has no water for water soluble terps?

2.) Is there another step, perhaps adding some 190 at the end of filtering when temps are slightly warmer but still below 0F to get more terps? Or can I process the left over material in a different manner solely for terp extract to add back?

3.) How careful about temps should I be during distillation/evaporation process to preserve terps? I have an analog heat/stir mantle, but it is connected to digital temperature controller and probe that can cycle it on and off. Should I keep my mantle temps below 110 on full vac?

4.) How long are people vacuum purging? 1 hours? 2 hours? 6 hours? I have been doing 30-45 at 110, mild stir to break film, 30 minutes at 115, mild stir, 30 minutes at 120, mild stir and then however long it takes at 125 to completely thin film.

I am really interested in any feedback that you might have about this process and terp preservation!!! Thanks all!!!

WFF

I now have 3 grades of material and place each in a labeled ziplock. The logic of doing this first step is to dry the material further without adding heat, and second to use less ethanol. I often do several pounds in 6-8 ounce runs, and it is basically a closed system that has no reduction in yield. Bubble bag is caked with kief at the very end, but I just place this bag in a traditional ice water bubble bags and get some nice bubble hash for me.

I then use a modified medical transport cooler as a sink with a 10x10x2 slab of dry ice to cool all material to around -40 F. The 10x10 holds 5x 500ml beakers, which is usually is 2x 1st pass kief, 1x 2nd pass kief & 2x bag leftover - all from the same strain. I have a second dry ice storage chest that I use to pre-cool the ethanol to -40 F/-50 F.

I follow many things from Skunk Pharm Research, but my filtering process is a little different since I now have fine kief and pulverized flower material, which takes much longer to filter. After testing 190, I only use 200 proof Extractohol to avoid contaminant pickup, as ethanol is exposed to material for 30-45 minutes total. I pour the -50F ethanol completely over the pre-cooled (20-30 minutes) material in all beakers and let sit for 10-15 minutes stirring a few times.

I use a 1000ml buchner funnel with 110mm Whatman #1 filters connected to BVV 1.5 Gallon Cold Trap and 3cfm vacuum pump. I installed a series of ball valves that let me isolate and throttle vaccum. I made what could be called a removable thermal diaper using radiant barrier material and foil tape that completely covers the sides and bottom of buchner funnel with about 3/4" gap around all sides. I then place about 1/2 pound of dry ice pellets around the outside of the funnel and cover it with another thermal lid made from radiant barrier. After cooling for 10-15 minutes, the glass frit and most of funnel is -30F - -40F, and it is ready to go.

I then place a fresh #1 filter and pour a small amount of chilled ethanol over filter and turn on vacuum to prime. I throttle vacuum (between pump and cold trap) so that no liquid is sucked into vacuum line from funnel and then completely pour the contents from 1st pass kief beakers into the filter. The fine kief quickly clogs the filter and requires an increase in vacuum (to about 75%) to maintain a nice steady filter pour. Depending on material - 6 ounces for this example, it takes about 5-7 minutes to filter 500ml from initial beaker soaking. After the material on filter dries out slightly, I will pour another 200-300ml chilled ethanol to maximize extraction.

Now, I pour the ~700ml of filtered ethanol into a clean beaker and set aside. After reattaching funnel to flask, I bring back to near full vacuum and pour the 2nd pass kief solution on top of the 1st pass still in the filter. This takes ~10 minutes to fully filter, after which I add the final 2 beakers of bag material solution. Bag material takes about 10-15 minutes to filter. 2nd pass and bag material stay in same flask. After fully filtering, I add another 200-300ml chilled ethanol to maximize extraction. At this point, the kief/bag material in the funnel is still at -20 - -30F, and depending on amount of starting material, it is a solid 1 1/2"-2" thick above filter pad.

I now have 2 grades of extract laden ethanol, which I can process separately or just add together for full body. The 1st grade is always deep amber, but the 2nd grade does pick up a very small shade of pale green, but after 30-60 minutes at room temperature, or immediately upon heating, all green goes away and a deeper amber than 1st remains. Both are crystal clear with no clouds. I then use a heating and stirring mantle and distillation apparatus to separate ethanol. Once ~85% of ethanol is evaporated, I collect material in small beaker and use 0.22um syringe filters. Solution goes from syringe directly into 120mm glass petri dishes, which have been marked and pre-weighed, and into AI 5-wall vacuum oven. I try to estimate 5-6 grams of shatter per petri dish.

Now, this brings me to the heart of my post. My first few tests using the system above produced the most rock hard shatter that I found nearly impossible to fully purge (at temps below 130). The 200 proof ethanol creates a thick film that bubbles have a very difficult time popping. I did some small tests that took temps of 160 under full vacuum (29.5) to purge. This is obviously not acceptable for creating vapable extracts.

I did the exact same steps above using 190 proof Everclear, and it does pick up a bit more green on 2nd/bag run, but it also picks up a cloudy element and other contaminants - clearly not acceptable either. However, I found that 190 processed material was easy to purge using a temp ramp from 110 to 125 over a few hours. It produced a much runnier extract far from shatter.

So... For my last test, I did my 200 proof process through distillation, but right before the 0.22um step, I poured a small amount of 190 Everclear in the solution. I used 40ml of Everclear for what I estimated would be 40 grams of shatter. 190 is 5% water, so 40 x .05 = 2ml of water added into solution. It turned out that this worked fantastic. It purged easily and created a nice hard taffy shatter.

However, my last batches of fully purged shatter have had little taste when I dab. Great and powerful high, but not much taste. I make both oral meds and vape products, and I have averaged about 25-27% shatter using some high quality flowers from Bodhi strains with this process.

I felt in necessary to better explain my process first, but my questions are the following:

1.) Am I even extracting all the terps, given the temps and fact that 200 proof ethanol has no water for water soluble terps?

2.) Is there another step, perhaps adding some 190 at the end of filtering when temps are slightly warmer but still below 0F to get more terps? Or can I process the left over material in a different manner solely for terp extract to add back?

3.) How careful about temps should I be during distillation/evaporation process to preserve terps? I have an analog heat/stir mantle, but it is connected to digital temperature controller and probe that can cycle it on and off. Should I keep my mantle temps below 110 on full vac?

4.) How long are people vacuum purging? 1 hours? 2 hours? 6 hours? I have been doing 30-45 at 110, mild stir to break film, 30 minutes at 115, mild stir, 30 minutes at 120, mild stir and then however long it takes at 125 to completely thin film.

I am really interested in any feedback that you might have about this process and terp preservation!!! Thanks all!!!

WFF