Hello Hash and Resin Fanatics.

I've wanted to try my hand at dry sieving for quite some time now, but just recently became disabled, so money is tight as I recover from my Bi-lateral hip replacement. Then I can fire up the garden again

Before spending a bunch of money,I wanted to explore some DYI projects(again bored) & came up with the following:

A simple cookie tin (you know the crappy Christmas cookie tin)

I used a can opener to remove the bottom.

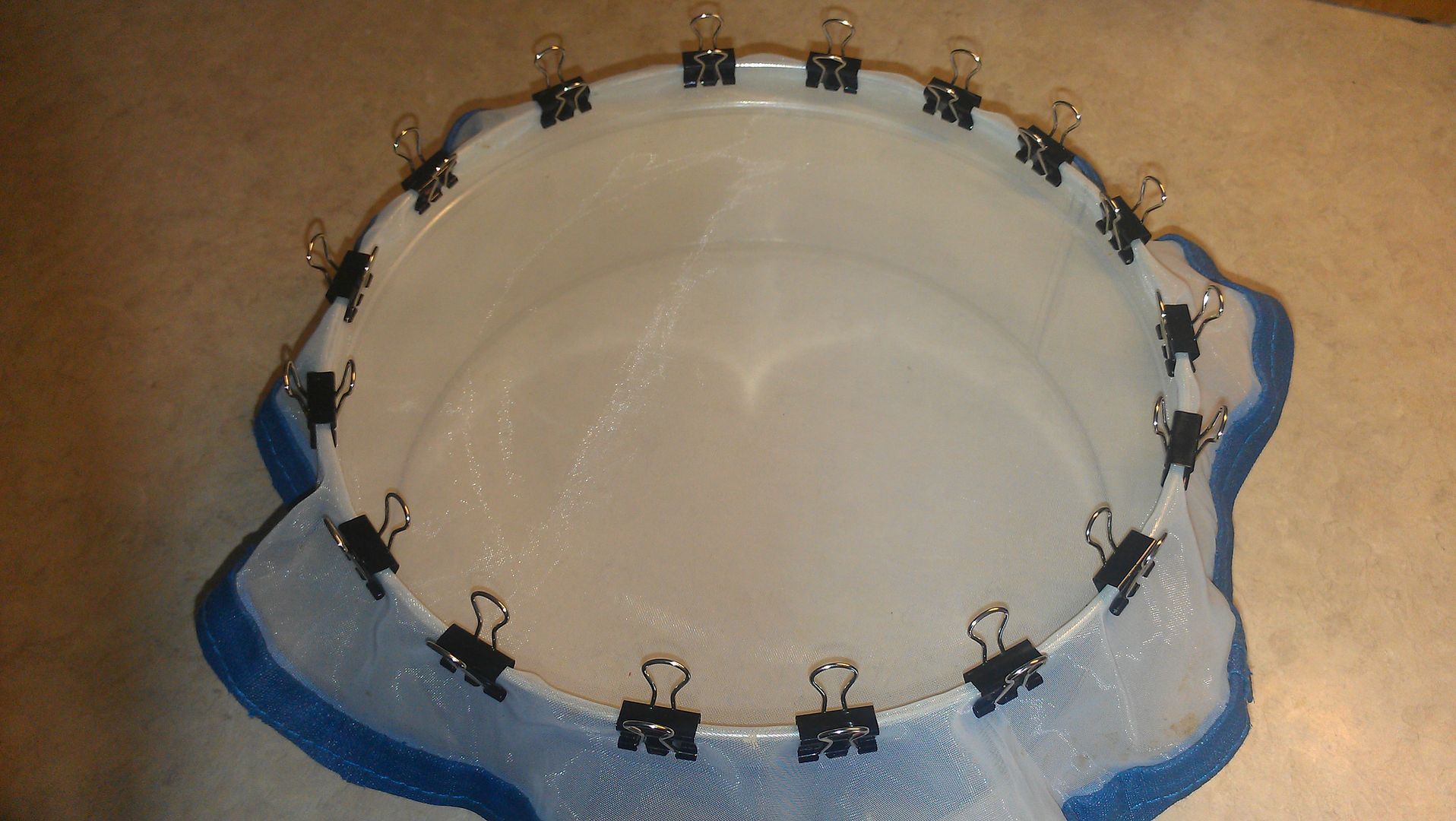

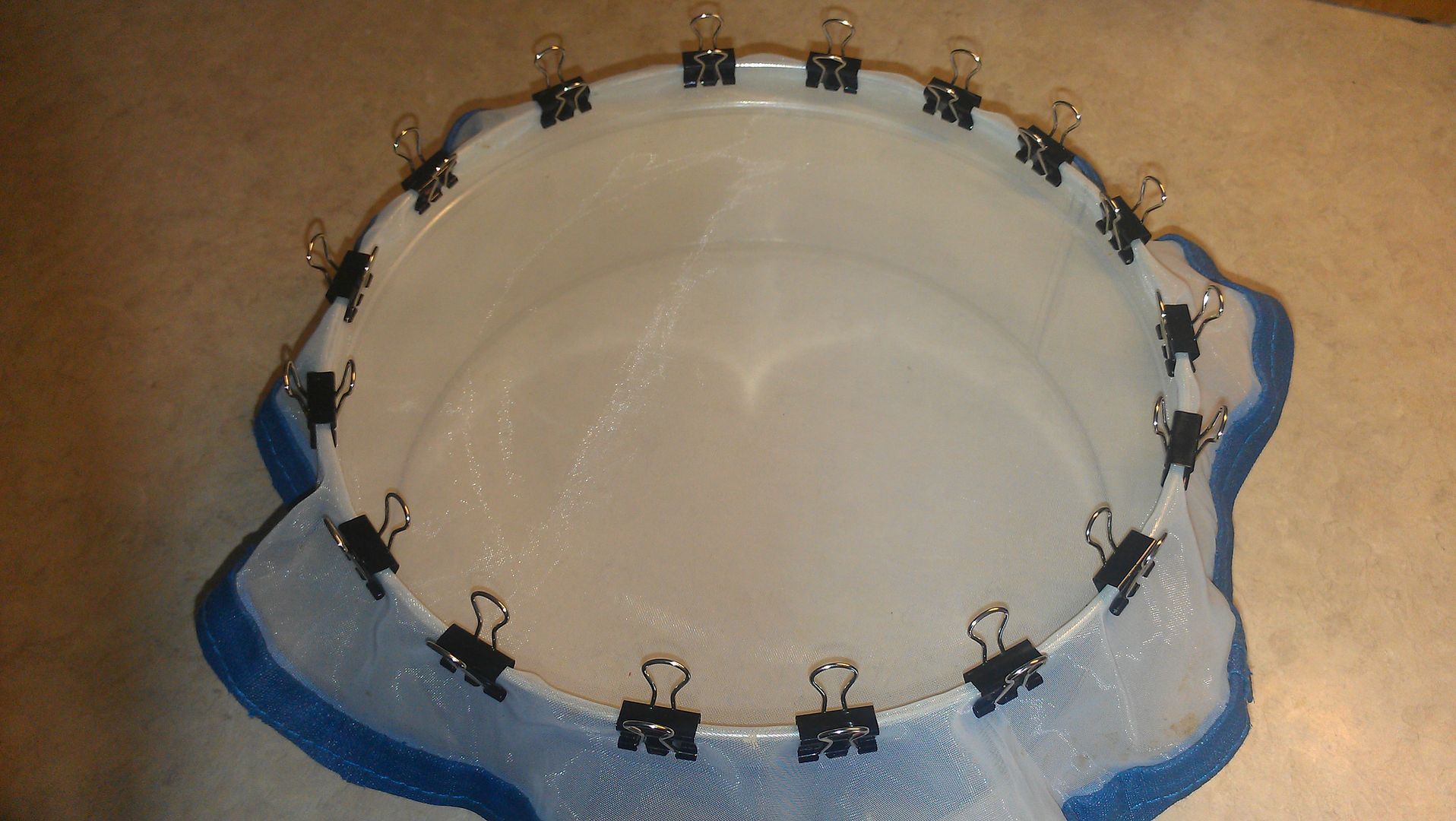

Cheap set of bubble bags- you only need the mesh.

Binder clips...

Clip one side, pull the mesh taught, and secure clip directly across the other side, repeat at a perpendicular angle, pulling the mesh as taught as possible.

I've used it only briefly and it worked fairly well..

Going to secure a 220micron on one side(top screen) & secure a 160 micron on the other side( bottom screen)

Will update once I've run some material through, only drawback so far is the small surface area.

I think this would work well with acoustical system.... Hope it works.

I've wanted to try my hand at dry sieving for quite some time now, but just recently became disabled, so money is tight as I recover from my Bi-lateral hip replacement. Then I can fire up the garden again

Before spending a bunch of money,I wanted to explore some DYI projects(again bored) & came up with the following:

A simple cookie tin (you know the crappy Christmas cookie tin)

I used a can opener to remove the bottom.

Cheap set of bubble bags- you only need the mesh.

Binder clips...

Clip one side, pull the mesh taught, and secure clip directly across the other side, repeat at a perpendicular angle, pulling the mesh as taught as possible.

I've used it only briefly and it worked fairly well..

Going to secure a 220micron on one side(top screen) & secure a 160 micron on the other side( bottom screen)

Will update once I've run some material through, only drawback so far is the small surface area.

I think this would work well with acoustical system.... Hope it works.

@ Tropic & Ester!

@ Tropic & Ester!