Hee, hee, hee, I previously built a press for squeezing glycerin, pressing cannabuttons, and making hash pucks, but I've been sitting back letting ya'll Rosin pioneers do the initial heavy lifting while I focused elsewhere.

The Rosin process has come far enough along to reach our R&D to do list and yesterday I picked up a 12 ton H press from Harbor Freight to provide the base unit.

I would use my existing press, but the fit would be close and heat transfer to the ram would be an issue. I like the HF design, because the jack is separated from the ram by the slide. I'll also adapt it to pressing glycerin and pressing cannabuttons and hash pucks.

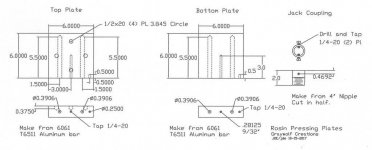

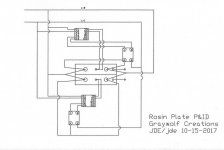

Here are my designs for a set of 6"X6" heated plattens, along with the PID for operating it.

This project is featured in our new The Alchemist Resource blog site launching 11-1-2017.

The Rosin process has come far enough along to reach our R&D to do list and yesterday I picked up a 12 ton H press from Harbor Freight to provide the base unit.

I would use my existing press, but the fit would be close and heat transfer to the ram would be an issue. I like the HF design, because the jack is separated from the ram by the slide. I'll also adapt it to pressing glycerin and pressing cannabuttons and hash pucks.

Here are my designs for a set of 6"X6" heated plattens, along with the PID for operating it.

This project is featured in our new The Alchemist Resource blog site launching 11-1-2017.

Attachments

Last edited: