Just watched this instructional video series on YouTube by BHOgart on using their system.

We don't have a BHOgart system per se, though we do have some BHOgart parts and the system does utilize a manifold, TR21, MT-69SS.

I don't believe that the configuration shown in the video is the best way, and want to know if my understanding is correct.

In their configuration, with a single line connected to the tank (even if it is split to both valves) the user must either be recovering, filling, or neither, but never both.

A better way would be to connect the liquid siphon valve to the input of the extractor and the line leaving the MT-69 to the vapor valve, routed through the manifold (blue side so you can see vacuum too).

This way the system can actually circulate solvent and is throttled via the manifold.

The voice over in the video says that the vacuum created by closing the input and running the pump expands the gas in the material column freezing it along with the material and the column.

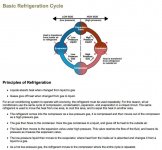

I thought that it was the other way around. That compressing solvent made it colder. I also think that until it rises above 31°, the solvent in the column is a liquid. I think that the process will make the column cold. Mine always does. But I thought it was due to pressure, not vacuum.

So am I right? Is my connection method sound in theory and practice?

Is there a Bat signal for Gray Wolf?

Somebody tag him or something.

We don't have a BHOgart system per se, though we do have some BHOgart parts and the system does utilize a manifold, TR21, MT-69SS.

I don't believe that the configuration shown in the video is the best way, and want to know if my understanding is correct.

In their configuration, with a single line connected to the tank (even if it is split to both valves) the user must either be recovering, filling, or neither, but never both.

A better way would be to connect the liquid siphon valve to the input of the extractor and the line leaving the MT-69 to the vapor valve, routed through the manifold (blue side so you can see vacuum too).

This way the system can actually circulate solvent and is throttled via the manifold.

The voice over in the video says that the vacuum created by closing the input and running the pump expands the gas in the material column freezing it along with the material and the column.

I thought that it was the other way around. That compressing solvent made it colder. I also think that until it rises above 31°, the solvent in the column is a liquid. I think that the process will make the column cold. Mine always does. But I thought it was due to pressure, not vacuum.

So am I right? Is my connection method sound in theory and practice?

Is there a Bat signal for Gray Wolf?

Somebody tag him or something.