I've been reading studies, whitepapers and talking to lighting engineers for years, both in the US and China. The LED industry is trying to hide from you that their lights are disposable after 10K hours of use, as output falls to 90% or lower.

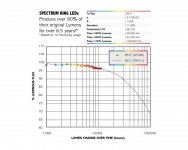

A couple reputable companies have addressed this (see chart from Spectrum King) but most are happy to sell you a panel with a promise that it will turn on for 10 years. They just dont tell you it will be at half it's original brightness. The only fix is to replace the panel.

The lighting engineers all know this, but marketing largely doesn't want it published because it means their expensive panels with a 5 year ROI are disposable, and that ROI won't be met.

A couple reputable companies have addressed this (see chart from Spectrum King) but most are happy to sell you a panel with a promise that it will turn on for 10 years. They just dont tell you it will be at half it's original brightness. The only fix is to replace the panel.

The lighting engineers all know this, but marketing largely doesn't want it published because it means their expensive panels with a 5 year ROI are disposable, and that ROI won't be met.