Drop That Sound

Well-known member

Ok guys, stay tuned, I just received a lightly used Samsung 6300 window unit. Was thinking about using as is (through wall or duct mod,etc)to switch from my current passive setup, but then I got to thinking..

I will only need to cool a smaller 7.5 x 6.5 x 6.25H sealed flower room with two 500-1100watt dimmable air cooled HPS lights, containing 2 separate 30 gallon 6 site RDWC systems, and also another small 20 gallon AERO/NFT/DWC hybrid system sitting in a passive veg cabinet with an 8 lamp t5 thats nearby.

I have a space in mind to place the unit, in a open faced cabinet thats right next to the flower room, perfect size and it already has a big vent leading outside at the back. Here is the awesome part, the vent (which is my old main outside air intake for flower room, w/ light proof box & filter) is lined up and exactly the size of the AC unit! If i remove my filter box contraption, that's not really needed anymore, I could slide the whole unit right in so the back would sit flush against the wall and damn near sealed into the inside lip of the vents frame, so that it exhaust straight out the wall. The intake would then be the cabinet itself sucking ambient lung room air in through the units factory vents instead of hanging outside. I would leave the housing on or make a custom one to direct the air out better and help trap any stray light that might escape through the back of the unit and outside the vent just in case. From outside if I put a better flowing mesh instead of the louvered grill I have it would look pretty cool I think seeing just the back of the unit.. through doubled up bug screen or something with a nice frame, not that that matters too much. Plus even better yet, inside just before the cab face frame I can drop the evaporator coil straight through a slotted cutout and down below the cabinets shelf and into a low profile foam board insulated RV water tank res I was going to make that would fit perfect. Its about thirty gallons short but long. I could possibly find something bigger or even add a reserve tank next to it later for more capacity.

Now.. If I go regular air cooled with the AC Id have to take up some space and box up a portion inside the already small flower room space, and flip the unit 90 degrees so it aims towards the same cabinet + vent.. or somewhere else and do extensive re-work to duct it through the wall and whatnot. I really don't have much room but could make it work. I know I don't want the unit to hang outside either. The worst part about this way to me is the fact that after all that work I would still have to build or buy a chiller & res.. which takes up more space, and is just 1 more unit that I almost don't even need except summer.

..So anyways I was thinking the conversion to a chiller (basically 6300 = 1/2HP) and centralizing all my cooling needs with one easily replaceable AC unit I have would be a nice way to go. I would build a multi panel with a bunch of cheap digital STC-1000 temp controllers for each pump in the the chiller res. 3 going to the 3 hydro systems with stainless coils, 1 going to a heater core hooked up to my 50 pint to blow thru, and 1(the main biggest line) going to a custom air handler and or ice boxes I will build.. from either triple stack heater cores, bigger alum radiator/tranny coolers, or just buy a nice sized exchanger.. whatever I find works best to cool the room itself and drain any condensation.

Also I would like to play around and possibly run another loop to another exchanger that would sit just outside the building, inline and up against my new intake vent that's for the lights closed loop ducting. I'm thinking in the dead of winter if running the fan at slow speed it would keep the freezing cold air (which sucks in and through the hoods and then blows right back to outside, through another exhaust vent that just above the new AC's cubby ) from causing condensation around the lights by actually pre-warming it some from the chiller res. Also, the chiller probably wouldn't be running at that time if at all but the air handler would be running in the room & warming up the chiller res, while the new exchanger would be sucking that heat away and chilling the res as well as the light. Not sure if that makes sense so I will make a diagram soon. Maybe even add a loop to help warm a pond or too another geothermal type coil outside!

) from causing condensation around the lights by actually pre-warming it some from the chiller res. Also, the chiller probably wouldn't be running at that time if at all but the air handler would be running in the room & warming up the chiller res, while the new exchanger would be sucking that heat away and chilling the res as well as the light. Not sure if that makes sense so I will make a diagram soon. Maybe even add a loop to help warm a pond or too another geothermal type coil outside!

I have more tools, materials laying around, patience, and time than money.. and a 1/2 ton of questions that I will add to the list.

1. Sound good? Crazy? Won't work? Not worth it?

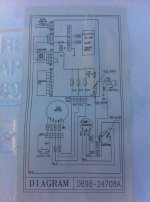

2. Can someone tell me the best way to control and re wire this particular AC into a chiller?(diagram included below).

3. Best liquid solution or mix to run in the system?

4. Should I remove all the fins on the evaporator, add an aquarium current pump aiming at it in the res, dip it in plastic? What else can I do to help extend the life or make it work more efficiently?

5. Will this type of setup get me by for at least 1 year until I could afford a better chiller to install? How long has or did yours last?

6. Off topic, but could one also dunk the hot condenser coil into its own cooler just like the evaporator coil into a cooler for a res? Then remotely mount a radiator and water or oil cool the hot side? I know its possible with a coaxial exchanger like in the factory WC'd models..And that some people hook up misters. But would it simply work like that without too much effort?

Thanks!

-Drop

I will only need to cool a smaller 7.5 x 6.5 x 6.25H sealed flower room with two 500-1100watt dimmable air cooled HPS lights, containing 2 separate 30 gallon 6 site RDWC systems, and also another small 20 gallon AERO/NFT/DWC hybrid system sitting in a passive veg cabinet with an 8 lamp t5 thats nearby.

I have a space in mind to place the unit, in a open faced cabinet thats right next to the flower room, perfect size and it already has a big vent leading outside at the back. Here is the awesome part, the vent (which is my old main outside air intake for flower room, w/ light proof box & filter) is lined up and exactly the size of the AC unit! If i remove my filter box contraption, that's not really needed anymore, I could slide the whole unit right in so the back would sit flush against the wall and damn near sealed into the inside lip of the vents frame, so that it exhaust straight out the wall. The intake would then be the cabinet itself sucking ambient lung room air in through the units factory vents instead of hanging outside. I would leave the housing on or make a custom one to direct the air out better and help trap any stray light that might escape through the back of the unit and outside the vent just in case. From outside if I put a better flowing mesh instead of the louvered grill I have it would look pretty cool I think seeing just the back of the unit.. through doubled up bug screen or something with a nice frame, not that that matters too much. Plus even better yet, inside just before the cab face frame I can drop the evaporator coil straight through a slotted cutout and down below the cabinets shelf and into a low profile foam board insulated RV water tank res I was going to make that would fit perfect. Its about thirty gallons short but long. I could possibly find something bigger or even add a reserve tank next to it later for more capacity.

Now.. If I go regular air cooled with the AC Id have to take up some space and box up a portion inside the already small flower room space, and flip the unit 90 degrees so it aims towards the same cabinet + vent.. or somewhere else and do extensive re-work to duct it through the wall and whatnot. I really don't have much room but could make it work. I know I don't want the unit to hang outside either. The worst part about this way to me is the fact that after all that work I would still have to build or buy a chiller & res.. which takes up more space, and is just 1 more unit that I almost don't even need except summer.

..So anyways I was thinking the conversion to a chiller (basically 6300 = 1/2HP) and centralizing all my cooling needs with one easily replaceable AC unit I have would be a nice way to go. I would build a multi panel with a bunch of cheap digital STC-1000 temp controllers for each pump in the the chiller res. 3 going to the 3 hydro systems with stainless coils, 1 going to a heater core hooked up to my 50 pint to blow thru, and 1(the main biggest line) going to a custom air handler and or ice boxes I will build.. from either triple stack heater cores, bigger alum radiator/tranny coolers, or just buy a nice sized exchanger.. whatever I find works best to cool the room itself and drain any condensation.

Also I would like to play around and possibly run another loop to another exchanger that would sit just outside the building, inline and up against my new intake vent that's for the lights closed loop ducting. I'm thinking in the dead of winter if running the fan at slow speed it would keep the freezing cold air (which sucks in and through the hoods and then blows right back to outside, through another exhaust vent that just above the new AC's cubby

I have more tools, materials laying around, patience, and time than money.. and a 1/2 ton of questions that I will add to the list.

1. Sound good? Crazy? Won't work? Not worth it?

2. Can someone tell me the best way to control and re wire this particular AC into a chiller?(diagram included below).

3. Best liquid solution or mix to run in the system?

4. Should I remove all the fins on the evaporator, add an aquarium current pump aiming at it in the res, dip it in plastic? What else can I do to help extend the life or make it work more efficiently?

5. Will this type of setup get me by for at least 1 year until I could afford a better chiller to install? How long has or did yours last?

6. Off topic, but could one also dunk the hot condenser coil into its own cooler just like the evaporator coil into a cooler for a res? Then remotely mount a radiator and water or oil cool the hot side? I know its possible with a coaxial exchanger like in the factory WC'd models..And that some people hook up misters. But would it simply work like that without too much effort?

Thanks!

-Drop

Attachments

Last edited: