AvidLerner

Member

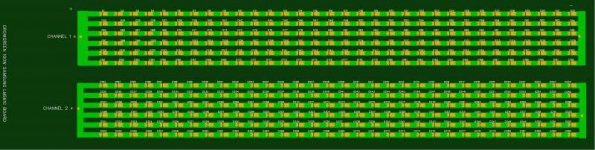

Recently I decided to design my own PCB for Samsung diodes. I really like the the Samsung LM561C diode as it can hit a maximum luminosity of 201umoles/w which is very impressive. In order to achieve this result the diodes have to be driven between 150mA - 165mA less than the maximum 200mA current of the diode.

There are a number of methods to achieve this result, one is thru current restriction, which I chose. To accomplish you must use parallel circuits with series circuits to achieve the result. Samsung LM561C diodes have a Forward Voltage of 2.9v each

My option is to string 32 diodes in series for a Forward Voltage of 92.8v. I placed six rows of these series circuits connected in parallel to create a circuit demand of 1200mA, which can not be achieved by circuit design; 1050/1200mA = 0.875 ratio allowing a maximum current flow of 175mA to each diode using a meanwell HLG-185H-C1050B driver constant current. Using a lesser driver will maintain he same ration, but lower the total current flow allowing softer use of the diodes with the same micro moles/watt capability.

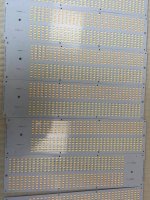

I attached a picture of the finished board that is currently under fabrication at Shenzhen Hansion Technology Company on Alibaba. I have the dxf files for the pcb as well as svg files.

namaste

There are a number of methods to achieve this result, one is thru current restriction, which I chose. To accomplish you must use parallel circuits with series circuits to achieve the result. Samsung LM561C diodes have a Forward Voltage of 2.9v each

My option is to string 32 diodes in series for a Forward Voltage of 92.8v. I placed six rows of these series circuits connected in parallel to create a circuit demand of 1200mA, which can not be achieved by circuit design; 1050/1200mA = 0.875 ratio allowing a maximum current flow of 175mA to each diode using a meanwell HLG-185H-C1050B driver constant current. Using a lesser driver will maintain he same ration, but lower the total current flow allowing softer use of the diodes with the same micro moles/watt capability.

I attached a picture of the finished board that is currently under fabrication at Shenzhen Hansion Technology Company on Alibaba. I have the dxf files for the pcb as well as svg files.

namaste