-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Off the shelf retail store screw-in LED and CFL bulb comparisons

- Thread starter blynx

- Start date

grouchy

Active member

Getting then warm helps and a sharp little screwdriver or something you can pry with. Doesn't matter much if they look pretty. A dremel tool with a cut off wheel would work too. The glue I saw was more like a silicon sealant and once it gave they popped off easily.Whats the best way to remove the glass globes off these led bulbs. The first one i tried to remove using an xacto knife but it broke on me.

They seemed to be sealed on with glue, was wondering if letting them run a bit would loosen them up.

thanks

I saw a 150w equivalent led at the store tonight. It had three way dimming where it could be run at 2600 lumens or two lower settings. That could really come in handy, how would it need to be wired up?

The way most of these bulbs are made with a bunch of individual LEDs. I would guess that the three way bulb just turns on more of those individual LEDs to increase the brightness. That would be cheaper than trying to build a more complicated controller.

I was thinking it would be a way to get the advantage of the diy dimmable leds with the convenience of conversion bulbs

These LEDs are dimmable.

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

[/FONT][FONT=Arial, Helvetica, sans-serif]

Getting then warm helps and a sharp little screwdriver or something you can pry with. Doesn't matter much if they look pretty. A dremel tool with a cut off wheel would work too. The glue I saw was more like a silicon sealant and once it gave they popped off easily.

What he said. I used an air powered cut off wheel, but I would imagine a dremel and a steady hand, a hacksaw or a pipe / hose cutter would probably work if you cant pop em off with a flat blade screw driver.

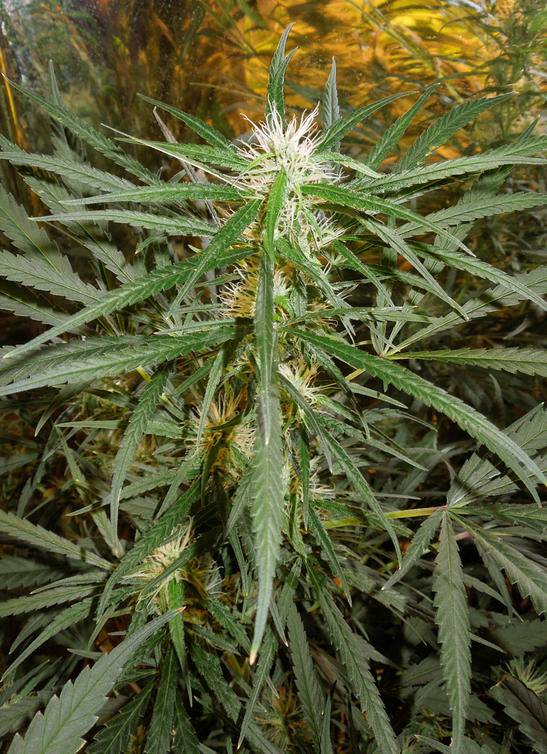

Purple Haze Malawi x Napalm at 4 weeks under the screw in LEDs is about 50% thicker than my last run under the 240w Blackstar:

Here's the previous plant under the blackstar at 5 weeks for comparison:

Now to be fair, both plants are from seed. The new one is a bit more malawi-napalm leaning where the last one was a bit more purple hazey...but I don't care. I am totally sold on the 16w bulbs!

Here's the previous plant under the blackstar at 5 weeks for comparison:

Now to be fair, both plants are from seed. The new one is a bit more malawi-napalm leaning where the last one was a bit more purple hazey...but I don't care. I am totally sold on the 16w bulbs!

Last edited:

Chloemobile

Active member

plants looking good terp!

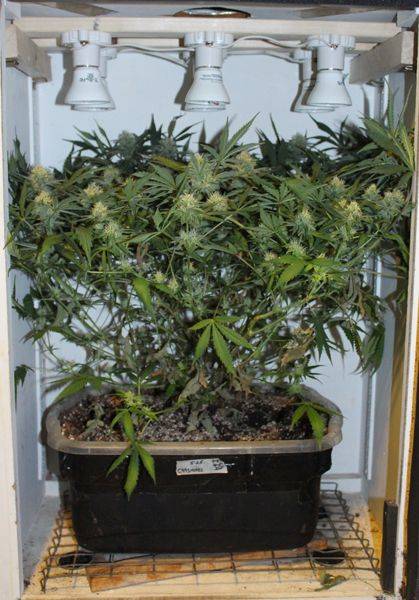

Here's the scrog cab after five weeks of flowering.

C99 x Shire (SSSDH)

Day 35 Flower

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

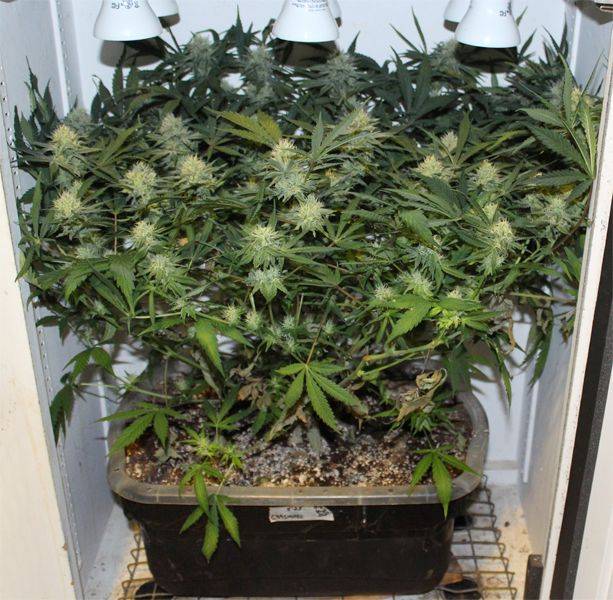

C99 x Shire (SSSDH)

Day 35 Flower

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

The last of my CFLs were replaced today.

My seedling veg area (2x2x2) was four 23w CFLs but I was tired of the heat the CFLs were making. So I replaced them with four 8w LED bulbs that I saw at Home Depot for $4 bucks each. According to my light meter, brightness is actually a little bit up overall at 1/4 the wattage.

Total wattage consumption for veg is 170w over 12sqft. Flowering is 385w over 16sqft (Blackstar 240w and nine 16w LEDs). Toss a couple fans on there and everything rounds out to 575w. I've built desktop computers that suck down more juice.

My seedling veg area (2x2x2) was four 23w CFLs but I was tired of the heat the CFLs were making. So I replaced them with four 8w LED bulbs that I saw at Home Depot for $4 bucks each. According to my light meter, brightness is actually a little bit up overall at 1/4 the wattage.

Total wattage consumption for veg is 170w over 12sqft. Flowering is 385w over 16sqft (Blackstar 240w and nine 16w LEDs). Toss a couple fans on there and everything rounds out to 575w. I've built desktop computers that suck down more juice.

Last edited:

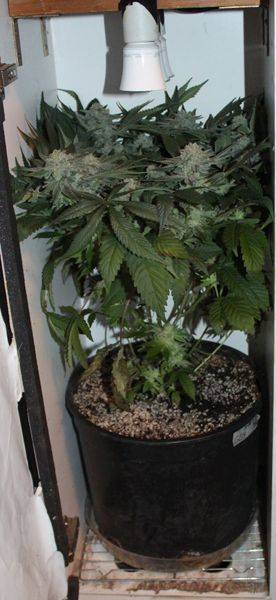

Here's the 11" x 11" cab after seven weeks of flowering.

Gorilla Glue #4

Day 49 Flower

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

[FONT=Arial, Helvetica, sans-serif]

[/FONT]

[/FONT]

Gorilla Glue #4

Day 49 Flower

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

[FONT=Arial, Helvetica, sans-serif]

blynx, you are the man. My thanks to you for everything you have done here. When everyone figures out what you have, CFLs are going to be a thing of the past. I had hoped to repay you with a hot tip, but homedepot.com seems to have just raised their prices. Until this past week sometime, they were selling the 6 packs of the Philips "60W" (8.5W, 800 lumens, 2700k) for $16.67 = $2.78 each. That's now $23.82 so still fair, but not a smokin deal. (They also had two packs of the same for like $4.97 but those disappeared off the site entirely about 3 weeks ago.) Will keep my eyes peeled for more bargains.

Here's an easier way, takes under a minute each.

Drill a hole through the side, 1/2" bit or whatever you have handy

Use a pair of needlenose to rip out a little piece of the globe

Insert the jaws of life, and twist/roll towards the center of the globe. Once the silicone goop starts to let go, the globe will pop right out

Comparison of Philips 100W (14.5W, 1500 lumens) and Philips 60w (8.5W, 800 lumens)...mmm, pornCOBs

Better get crackin

What he said. I used an air powered cut off wheel, but I would imagine a dremel and a steady hand, a hacksaw or a pipe / hose cutter would probably work if you cant pop em off with a flat blade screw driver.

Here's an easier way, takes under a minute each.

Drill a hole through the side, 1/2" bit or whatever you have handy

Use a pair of needlenose to rip out a little piece of the globe

Insert the jaws of life, and twist/roll towards the center of the globe. Once the silicone goop starts to let go, the globe will pop right out

Comparison of Philips 100W (14.5W, 1500 lumens) and Philips 60w (8.5W, 800 lumens)...mmm, pornCOBs

Better get crackin

Attachments

HuffnPufferfish

Member

thats the easy way? well mkay but i place em on carpet, take a small hammer, smack the bulb few times and the cover falls off like that (plastic disforms, glue releases)

HuffnPufferfish

Member

are you gonna put those ALL in sockets? or pull em apart and connect them?

Not sure yet, 36 of those 60W would be 28,800+ lumens and 306W, which would be pretty good bang for the buck for well under $150. Also have 8 of the 100W for another 12,000+ lumens and 116W. I had initially purchased these to rig up some supplemental lighting for my Mars blurples, but I might go full bore Sahara desert lighting in the closet. We shall see.

Re: globe removal - Shit, I thought I was a genius. Gonna try your hammer method right now.

Re: globe removal - Shit, I thought I was a genius. Gonna try your hammer method right now.

Hammer method not working for me, Philips apparently uses top quality Chinese plastic. Big dents in the globe and no deformation.

Another point I wish I could edit:

When you rip into the bulb with the needlenose, look for the spot with no silicone. Seems like all of them have a little spot. Start twisting there and you are done in 30 seconds.

We now return you to your regularly scheduled thread.

Another point I wish I could edit:

When you rip into the bulb with the needlenose, look for the spot with no silicone. Seems like all of them have a little spot. Start twisting there and you are done in 30 seconds.

We now return you to your regularly scheduled thread.

HuffnPufferfish

Member

put them in a socket for 10min, so it heats up, forgot to mention that, if they wont let go after a good slam

after i harvesting ill be prying to open to see how/what i need to fix to line them all up on a piece of metal with some fans over it, should be awesome seeing how a FEW of these already working magic

after i harvesting ill be prying to open to see how/what i need to fix to line them all up on a piece of metal with some fans over it, should be awesome seeing how a FEW of these already working magic

Already finished! 10 minutes x 36 = Ain't nobody got time fo dat!

I had considered what you mention, a sort of COB type setup, but I think the simplicity of the screw-in bulbs is a big part of the draw, especially for what I am probably going to do. Planning to mount cleats to 1"x4" boards so I can have long, thin lighting to use in conjunction with the overhead blurples. Finding alumin(i)um stock around the right size and thick enough to work as a heatsink wouldn't be hard, but then all the drilling and tapping and finding an appropriate driver etc., meh. Trying to keep it cheap and fairly low-tech. I've been pondering a couple designs that could double as both overhead and side lighting that will be a lot easier to fabricate in wood versus aluminum too.

I had considered what you mention, a sort of COB type setup, but I think the simplicity of the screw-in bulbs is a big part of the draw, especially for what I am probably going to do. Planning to mount cleats to 1"x4" boards so I can have long, thin lighting to use in conjunction with the overhead blurples. Finding alumin(i)um stock around the right size and thick enough to work as a heatsink wouldn't be hard, but then all the drilling and tapping and finding an appropriate driver etc., meh. Trying to keep it cheap and fairly low-tech. I've been pondering a couple designs that could double as both overhead and side lighting that will be a lot easier to fabricate in wood versus aluminum too.

HuffnPufferfish

Member

nothing is set in stone yet, atm im running them in e27 sockets, but since sockets make up 20% of the costs, im saving a few bucks by doing the cob style thingy, but as you said, if you go copy cob too much youll end up with the same amount of work (in the end will be fine i guess, youll save some bucks vs real cobs) so ima ponder some more since my room/box will get an update so ill mess around, ill at least want to remove the socket costs