Speed of green

Active member

So im at the point of making final revisions to my outdoor ppk design, i think its fairly simple, just wanted to run it by the crowd and get some final input.

All the plumbing will be schedule 40 pvc with grommets, i really wanted to go with the black goodyear hose but it just gets way too hot in the sun.

I want the redundancy and stability of a smaller ppk system but on a large scale.

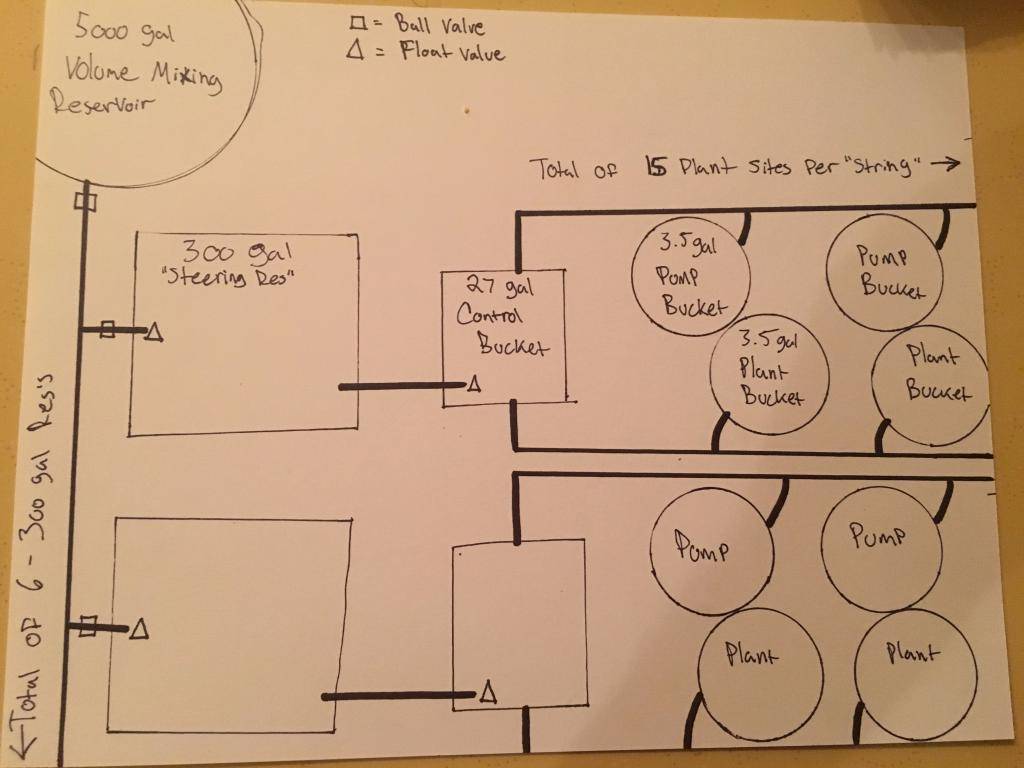

The system starts with a 5000 gal reservoir that gets mixed with jacks and calnit & ph'd 5.5-5.8ish

from there it goes into one of six 300 Gal reservoirs, these reservoirs are separate from each other and are the beginning of independent ppk systems, these 300gal volumes will be ph adjusted to the specific needs of each system

after the 300 gal res there is a 27 gal control bucket that manages the air gap.

connected to each 27 gal tote are 15 plant buckets and 15 pump buckets.

The pumps are eco 66 MAG DRIVE pumps.

here is a little diagram i made depicting the layout.

My handwriting and art skills could use some work but i hope this helps for a visual reference.

This is a plant layout design, 45 plants per greenhouse, 2 greenhouses.

The greenhouses are 130'Lx20'Wx16'H

The circles in the picture are 7'6" in diameter, i will flower the plants before they get to that size to maintain walkways.

Thanks for reading folks, i really appreciate any input!

All the plumbing will be schedule 40 pvc with grommets, i really wanted to go with the black goodyear hose but it just gets way too hot in the sun.

I want the redundancy and stability of a smaller ppk system but on a large scale.

The system starts with a 5000 gal reservoir that gets mixed with jacks and calnit & ph'd 5.5-5.8ish

from there it goes into one of six 300 Gal reservoirs, these reservoirs are separate from each other and are the beginning of independent ppk systems, these 300gal volumes will be ph adjusted to the specific needs of each system

after the 300 gal res there is a 27 gal control bucket that manages the air gap.

connected to each 27 gal tote are 15 plant buckets and 15 pump buckets.

The pumps are eco 66 MAG DRIVE pumps.

here is a little diagram i made depicting the layout.

My handwriting and art skills could use some work but i hope this helps for a visual reference.

This is a plant layout design, 45 plants per greenhouse, 2 greenhouses.

The greenhouses are 130'Lx20'Wx16'H

The circles in the picture are 7'6" in diameter, i will flower the plants before they get to that size to maintain walkways.

Thanks for reading folks, i really appreciate any input!

.....

.....