zeke99

Active member

My guess would be a restriction in the drip ring..not enough holes.

Cable ties do help, two on each barb. My rings are about 12 long with 12 holes delivering a quart from the 185 gph pump on each site.

My vegging 12 bucket system with one 1200gph mag drive pump has large store bought halo rings and they have 54 holes each. I get a trickle out of each one. I dont think it is giving me a quart so that is next on my things to do. I got to make some to restrict some of the flow.

Hope that helps

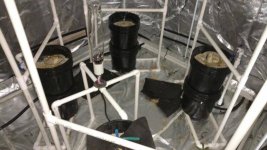

I think it might help. Perhaps the pump is too strong and like you said, there are too few holes in the drip ring. I punched 10 in each and the piece of tubing for each ring is roughly 10 inches long.

The pump only fires for 6 seconds!

....

....