-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

full melt dry sift tutorial/discussion

- Thread starter time2shine

- Start date

time2shine

Member

awesome daub i dont see why it wouldnt work.. im stoked to see how it turns out! does your screen have a wooden frame?

some things that would help us refine this more would be.

to try this with a wood frame to see if that makes a difference using the same card and parchment

try it with a different card to see if that matters using the same parchment and screen

and try it with a different kind of paper using the same screen and card...

mofeta the first run i did i had the rh down around 26-28 and the second time it was up around 50 so i dont think the humidity has much to do with it .. might be different in high humidity areas though

some things that would help us refine this more would be.

to try this with a wood frame to see if that makes a difference using the same card and parchment

try it with a different card to see if that matters using the same parchment and screen

and try it with a different kind of paper using the same screen and card...

mofeta the first run i did i had the rh down around 26-28 and the second time it was up around 50 so i dont think the humidity has much to do with it .. might be different in high humidity areas though

time2shine

Member

ya mofeta i always keep it on the cardboard

You can use nugs with my tek.. but it takes a great deal of 'drying' to get them ready to run.

I think dry sifting as a 'whole' is still in the infancy.. but it's about to blow up big time in the next couple years..

Glad to be here contributing.

Cheers all.

It is not just drying, even really dry nugs have problems.

What works best is to do it in stages, sift them a little bit and then wait to allow to dry more or out gas the terpenes a bit then sift again etc. You need to wait a while between sifts the more time the higher the humidity.

-SamS

Daub Marley

Member

Yeah it's a wood frame I'll conduct some experiments to answer those questions as well as some of my own.

I'll conduct some experiments to answer those questions as well as some of my own.

If it doesn't work I'll keep at it until technique and results are exactly the same.

If it doesn't work I'll keep at it until technique and results are exactly the same.

Daub Marley

Member

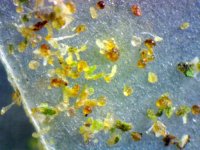

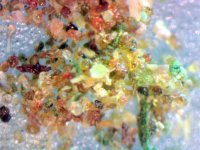

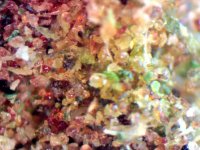

Ok so here it is. I started with at least one year old material that was not any good to smoke.

The wax paper did a pretty good job at removing the heads from a very contaminated sample.

After the first one it seems that things did not get much better. I think this could be because I brushed it around too much and built a charge that was too great to separate the heads from the plant material. I did notice stuff standing on end when attached to the parchment paper.

I used 50 micron screens and some of the smaller heads got through, so maybe a slightly smaller one would retain them. My frame was wooden, and the card was plastic.

The wax paper did a pretty good job at removing the heads from a very contaminated sample.

After the first one it seems that things did not get much better. I think this could be because I brushed it around too much and built a charge that was too great to separate the heads from the plant material. I did notice stuff standing on end when attached to the parchment paper.

I used 50 micron screens and some of the smaller heads got through, so maybe a slightly smaller one would retain them. My frame was wooden, and the card was plastic.

Attachments

Last edited:

time2shine

Member

interesting doesn't seem like it worked the same .. although id rip picture 3... so you used a wooden framed screen.. was the parchment the same kind? what about the card?

Daub Marley

Member

Yeah I think it was charged too much, but it still worked really well IMO. My setup is a wooden framed nylon screen, a translucent flexible plastic card, a toothbrush, and Reynold's brand parchment was used. I'll try again tomorrow and see if I can improve anything.

Would have been nice to know that you were giving intentionally faulty advice to protect your future interests. Inexcusable to keep that bit to yourself, IMO.Those will work.. I gave those as my last tutorial sizes. I did that for two reasons.. one because it does work pretty well, and two because I was a bit guarded with this method and didn't want it to be 'taken' by others.. which of course has happened.

I kept the actual sizes I use pretty under wraps. At least for now.

DrySiftWizrd

Member

Would have been nice to know that you were giving intentionally faulty advice to protect your future interests. Inexcusable to keep that bit to yourself, IMO.

It doesn't work using the sizes and method I shared on here for *free*?

Really?

Ok so here it is. I started with at least one year old material that was not any good to smoke.

The wax paper did a pretty good job at removing the heads from a very contaminated sample.

After the first one it seems that things did not get much better. I think this could be because I brushed it around too much and built a charge that was too great to separate the heads from the plant material. I did notice stuff standing on end when attached to the parchment paper.

I used 50 micron screens and some of the smaller heads got through, so maybe a slightly smaller one would retain them. My frame was wooden, and the card was plastic.

Yeah I think it was charged too much, but it still worked really well IMO. My setup is a wooden framed nylon screen, a translucent flexible plastic card, a toothbrush, and Reynold's brand parchment was used. I'll try again tomorrow and see if I can improve anything.

Hi Daub

You called it wax paper a few times, but then specified it was Reynolds parchment, right? Was paper is totally different and should never be used when doing anything with resin, unless you like smoking wax. I think you know this, and I'm being anal, but I like to be real clear about things when investigating something.

Did you sift the resin down onto the 50micron screen? I don't know what size time2shine used, but I bet it was around 140 or so. If you just put that contaminated resin on a 50 and tried to clean that with the parchment, I don't think that is what time2shine did.

I am really glad you are trying to replicate this method. That is the single most effective route of exploration at this stage. I like the sentiment you expressed about persisting until you succeed, that is a very powerful attitude/mindset. You will get results.

I only process resin about twice a year. I am real set in my ways on this. BUT, I am sorely tempted to break my own rules and do some ahead of time, just to check this out. Probably won't though, I am weird about doing things a certain way. So I am glad a bright person like you is pursuing it, I can experiment vicariously by observing you!

time2shine

Member

if you have a pile of "food grade" sift under your yellow screen from using bubblemans method you can scrape it up put it back on top of the yellow screen and go over it with the parchment a few times and it will remove all the heads under 70ui that fell through. its like the 45ui bag of dry sift..

time2shine

Member

my upper screen is 110 lpi(160ui i think) and my bottom screen is 200(70ui i think).. if you just wanted all the heads under the 70 screen in the same batch as the stuff u clean from on top of the yellow screen you could just switch out the bottom screen for like a 25 or 40ui.

aluminum hold 59% of the charge the copper does so it is very conductive just something to think about.

aluminum hold 59% of the charge the copper does so it is very conductive just something to think about.

DrySiftWizrd

Member

^^That's why i'm not a fan of aluminum and my method.

It doesn't work as well.

It doesn't work as well.

Daub Marley

Member

No your absolutely right. It's Reynold's brand parchment paper that was used not wax paper.Hi Daub

You called it wax paper a few times, but then specified it was Reynolds parchment, right? Wax paper is totally different and should never be used when doing anything with resin, unless you like smoking wax. I think you know this, and I'm being anal, but I like to be real clear about things when investigating something.

I sifted it a couple of times to refine it just a bit. The screen used to sift was a 200 mesh stainless steel (approx. 88 micron sized holes), so that probably had something to do with it. I'm going to order a 100-115 mesh. I'll follow up.Did you sift the resin down onto the 50micron screen? I don't know what size time2shine used, but I bet it was around 140 or so. If you just put that contaminated resin on a 50 and tried to clean that with the parchment, I don't think that is what time2shine did.

Thanks man, I appreciate that! I am an engineering student, so this an extremely interesting challenge for me. I should be able to figure out all the science behind what's going on with the help of people like yourself.So I am glad a bright person like you is pursuing it, I can experiment vicariously by observing you!

I was lucky to have some old crap lying around to experiment with, but I believe its important to let the heads mature to a certain size so they can be decapitated easily (if your waiting for harvest). It makes the yield higher and cleaner, but if you have an experiment you want me to try I will be more than glad.I am sorely tempted to break my own rules and do some ahead of time, just to check this out. Probably won't though, I am weird about doing things a certain way.

The nylon should be acting as an insulator preventing the flow of electrons to/from the aluminum frame, so it is unlikely to make much of a difference. I'll certainly investigate further though with experiments.aluminum hold 59% of the charge the copper does so it is very conductive just something to think about.

DrySiftWizrd

Member

Mesh should have nothing to do with it. If you are creating static it should pick up resin heads regardless of what size screen/mesh they're sitting on.

Do more threads = more static being held? I doubt it?

Do more threads = more static being held? I doubt it?

time2shine

Member

way to go daub keep it up! i can tell you're going to have this all dialed in in no time... quick correction just to clear up something i said before you go and purchase anything .. i just checked bubblemans conversion chart .. the 110lpi screen is 137ui and the 200lpi screen is 74ui

time2shine

Member

wow daub now that i look at your pictures again and notice the captions at the bottom i see what your saying.. that looks like it worked alot better then i thought.. you just got some seriously mature resin there! a couple even look green... what was the material like that you started with ?? was it really old? how much do you think you ended up with for what you started with ?? decent yield?

Daub Marley

Member

Yeah I think its around two years old. The heads are really amber, and the thing to keep in mind is this stuff was really bad. The yield wasn't great, but I'll figure out why.wow daub now that i look at your pictures again and notice the captions at the bottom i see what your saying.. that looks like it worked alot better then i thought.. you just got some seriously mature resin there! a couple even look green... what was the material like that you started with ?? was it really old? how much do you think you ended up with for what you started with ?? decent yield?