It's finally done

back shot

I used a bunch of bho scraps I had laying around, way to much imo, all from tubular extraction. I dissolved it all in warm everclear, it was very dark amber color, froze over night with the freezer on full blast. I filtered with a frozen reusable coffee filter in the freezer. I still saw stuff in there so I froze and filtered again. There was still some specks in it but at this point I realized I needed a better filtration system or I need to do less at at time with more everclear. Purging took forever and a day on a hot plate.

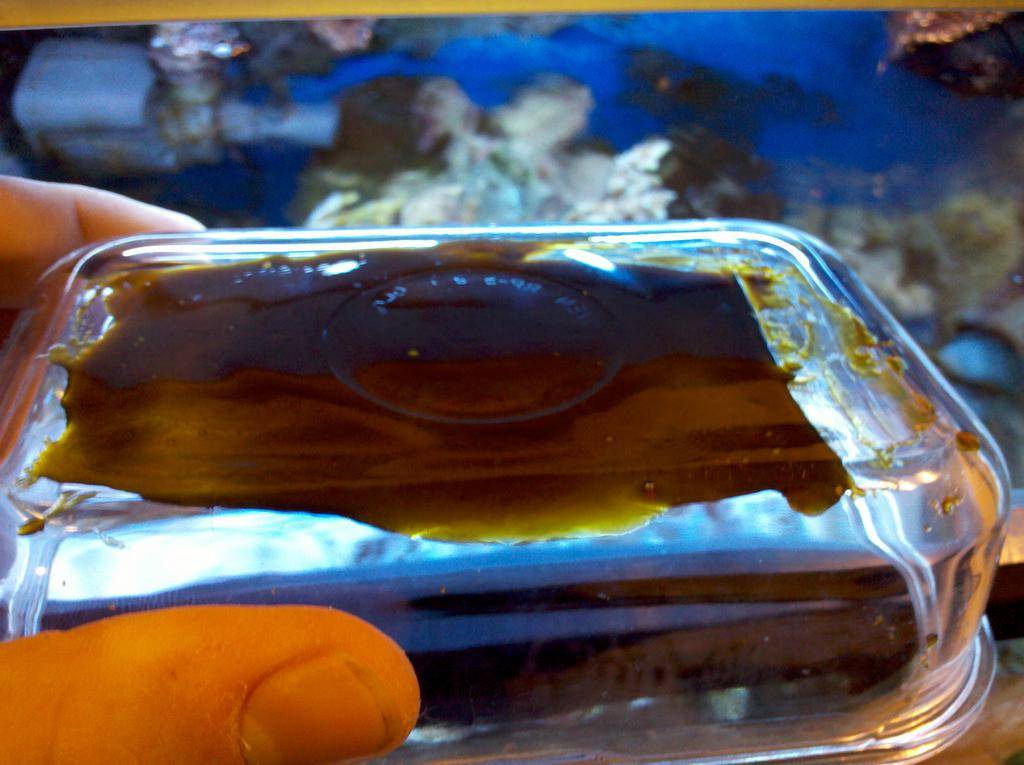

That's what it looked like in the purging pan after almost a full day and couple of scrapings and thinning it out flat.

The taste is super smooth a lot better than iso wash.Still nowhere near the taste of good bho imo.The texture is one step away from shatter at about 70 degrees F, if you bend it slowly it is pliable but any fast movement and it will break, put it in the freezer and its like glass. I do have a lil more confidence to do the next run start to finish with the intent of making aa amd only using one strain.

Thanks again jump, I think I will get it next time.

Hee, hee, hee, nice color