Symbiotic AD

Member

Hey guys,

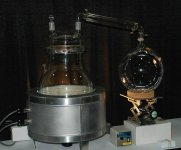

I am looking to set up a short path distillation unit in my lab and I am unsure where to start. I don't want to purchase anything like the Kugelrhor or any other system, simply because I am unsure if the application is even worth pursuing. I currently have a Buchi rotary vap and a lot of various glassware and equipment, and hoping I can fab something for testing purposes. If you guys have any information on how to do this it is greatly appreciated, or if I'm a fool for not just purchasing the equipment let me know.

Thanks,

Sym

I am looking to set up a short path distillation unit in my lab and I am unsure where to start. I don't want to purchase anything like the Kugelrhor or any other system, simply because I am unsure if the application is even worth pursuing. I currently have a Buchi rotary vap and a lot of various glassware and equipment, and hoping I can fab something for testing purposes. If you guys have any information on how to do this it is greatly appreciated, or if I'm a fool for not just purchasing the equipment let me know.

Thanks,

Sym