Drop That Sound

Well-known member

Update on my own designs:

Gonna find a middle ground, and take the advice of other SIL growers here, and not go too overkill with 930w 4' x 3' fixtures.

I heard there is diminishing returns over 40w per sq ft, but thinking that's with the lights hanging above the canopy a certain distance?.

I do see the benefit of going a little overboard, to the point I have to raise the lights up, and getting more light in places that otherwise would get blocked out. I also see the benefit of using less bulbs, with less electricity, and keeping them a lot closer, but thats not my main goal.

I'm not gonna go too much over 40w per sq ft now, and i'm new to LED growing with anything more than a few SILs, especially the 1600+ lumen ones. Never really flowered fully with LED, but do have my buddies that do and have watched them grow my same strains I have. I don't wanna go too much, but also fall short either if I can handle more light...

While I can get around a gram per watt with HPS in the same spaces I plan to hang the SILs, Its hard to wrap my head around the idea that less than 600w of LED light bulbs is gonna pull what a 1000 HPS will, especially when I grow monster single plants sometimes.

I just have the 1 gpw stuck in my head but would be awesome if I could hit 1.5 with them. But that changes my whole design, and i'm kinda OCD when I build stuff, especially when i'm about to hack both ends off over 100 bulbs give or take. Unlike most SIL arrays I won't be able to change much after my build, without starting over, so getting it right the first time is important.

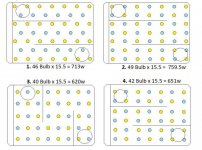

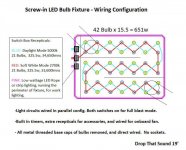

Here are some more configurations I been thinking about below.

Keep in mind the main design on the first page, its a box with air flowing through, which I want to disperse evenly over every opened up bulb, and also keep the electrical runs nice and tidy, while also leaving room for recepticals and household light switches/cover plates to turn on different sets & or rows. The area on the left side of the pics will be a few inches of space to do just that, and the end I have access too in the room.

I'm gonna pick up 2 4x8 sheets of whatever material this wknd (1/4 ply, thinner hard tempered mdf with white coating, etc) I deem the best for the top and bottom panels, and use nice 3/4 plywood strips about 4" for the sides of the box. Maybe a little bit of framing depending on the need.

Everything on the exteriors will be routed with a small radius and all the wood areas painted or covered with laminate or something to look real nice. Maybe some trim mouldings on the corners, we'll see. Even the many holes will have a radius routed on the bottom side. And little feet to protect the PCBs if I lay it down flat on the ground.

The tops will be removable for access.

Gonna find a middle ground, and take the advice of other SIL growers here, and not go too overkill with 930w 4' x 3' fixtures.

I heard there is diminishing returns over 40w per sq ft, but thinking that's with the lights hanging above the canopy a certain distance?.

I do see the benefit of going a little overboard, to the point I have to raise the lights up, and getting more light in places that otherwise would get blocked out. I also see the benefit of using less bulbs, with less electricity, and keeping them a lot closer, but thats not my main goal.

I'm not gonna go too much over 40w per sq ft now, and i'm new to LED growing with anything more than a few SILs, especially the 1600+ lumen ones. Never really flowered fully with LED, but do have my buddies that do and have watched them grow my same strains I have. I don't wanna go too much, but also fall short either if I can handle more light...

While I can get around a gram per watt with HPS in the same spaces I plan to hang the SILs, Its hard to wrap my head around the idea that less than 600w of LED light bulbs is gonna pull what a 1000 HPS will, especially when I grow monster single plants sometimes.

I just have the 1 gpw stuck in my head but would be awesome if I could hit 1.5 with them. But that changes my whole design, and i'm kinda OCD when I build stuff, especially when i'm about to hack both ends off over 100 bulbs give or take. Unlike most SIL arrays I won't be able to change much after my build, without starting over, so getting it right the first time is important.

Here are some more configurations I been thinking about below.

Keep in mind the main design on the first page, its a box with air flowing through, which I want to disperse evenly over every opened up bulb, and also keep the electrical runs nice and tidy, while also leaving room for recepticals and household light switches/cover plates to turn on different sets & or rows. The area on the left side of the pics will be a few inches of space to do just that, and the end I have access too in the room.

I'm gonna pick up 2 4x8 sheets of whatever material this wknd (1/4 ply, thinner hard tempered mdf with white coating, etc) I deem the best for the top and bottom panels, and use nice 3/4 plywood strips about 4" for the sides of the box. Maybe a little bit of framing depending on the need.

Everything on the exteriors will be routed with a small radius and all the wood areas painted or covered with laminate or something to look real nice. Maybe some trim mouldings on the corners, we'll see. Even the many holes will have a radius routed on the bottom side. And little feet to protect the PCBs if I lay it down flat on the ground.

The tops will be removable for access.