Ahh screw it, it is too cold outside to do anything, and what fun is only testing a middle of road application, so I will go straight to the hard stuff - 190 proof grain alcohol. A torture test of -78C(ish) will soon commence...

-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY -50C Recirculating Chiller

- Thread starter WaterFarmFan

- Start date

Consuming large quantities of long cured Bangi Haze & Zamaldelica will also be part of the test... Haha

Just curious, when did own/use a chugger? Was yours inline or center input? I read center has better flow than inline. I have seen two versions used on ebay, and I wonder if you had an earlier model? No idea if it will last or replicate results at higher viscosity.

This is the first external fluid pump that I have ever owned, but I have gone through more a dozen of the submersible ones for hydroponic applications. This thing puts all of those to shame.

I had the in-line model CPSS-IN-1 (115v) from Amazon. I ordered it sometime around July/August 2017

I had the in-line model CPSS-IN-1 (115v) from Amazon. I ordered it sometime around July/August 2017

Interesting. I wonder if the inline is more difficult to prime? For initial testing, I added a clear piece of silicone tubing to the top of the output, so that I could see when primed. I had to slightly lift my reservoir, but the air inside the pump immediately cleared.

what kind of setup are you using for the terpene evaporation? Vacuum steam distillation? rotovap?

Hey Hash head. I am just using a vacuum oven with a nitrogen backfill to volatilize terpenes and now a 4-stage condenser/cold trap setup to collect them. I mimic a freeze drier in parts of my process (beginning and to periodically cool material to minimize decarbing), by using liquid nitrogen to freeze material which induces sublimation, but ~70% involves heat (~215F max) at various vacuum levels causing evaporation. No external solvents, including water, are added, so I just use basic separation techniques to isolate terpenes from natural hydrosol. With enough process time, I think that a small amount of water could be added to pulverized flower material that has been dried and cured, but there is already so much h20 in fresh frozen that it seems counter-productive, because at the end of this process, I want material that is close to dry, so that I can do a -50C ethanol extraction to get all the cannabinoids as well as any terpenes still trapped inside trichomes.

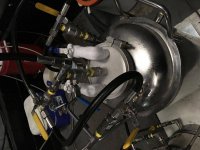

After a quick ponder of using 190 proof alcohol next to motor with open slots spinning at 3500 RPM, I decided that some basic precautions were in order. First, I secured the pump and raised it ~2" on a footer board to be more inline with the reservoir output. With a bit of spare aluminum sheeting and some foil tape, I made a covering that should prevent any accidental etoh from directly entering the motor.

I need to properly secure my hose fittings, but it is ready to test, and I will be straight to a torture test of 4-6 hours at -78C. If it is going to break/fail, I want it to happen sooner than later.

I need to properly secure my hose fittings, but it is ready to test, and I will be straight to a torture test of 4-6 hours at -78C. If it is going to break/fail, I want it to happen sooner than later.

I've been using a pump from Eheim for about two years. First one lasted about a year and the second one is on about 6 months or so. I use my old 10gal vac chamber pot filled with a denatured alcohol/dry ice slurry and another pot inside that with the pump and another dry ice slurry. My temps are always around -40.

Attachments

Typically a flooded section pump, that requires liquid in it to function.[FONT=Arial, Helvetica, sans-serif]Interesting. I wonder if the inline is more difficult to prime? For initial testing, I added a clear piece of silicone tubing to the top of the output, so that I could see when primed. I had to slightly lift my reservoir, but the air inside the pump immediately cleared.

[/FONT]

Interesting. I wonder if the inline is more difficult to prime? For initial testing, I added a clear piece of silicone tubing to the top of the output, so that I could see when primed. I had to slightly lift my reservoir, but the air inside the pump immediately cleared.

[FONT=Arial, Helvetica, sans-serif]!@#$%^&*() having edit problems

[/FONT]

After a quick ponder of using 190 proof alcohol next to motor with open slots spinning at 3500 RPM, I decided that some basic precautions were in order. First, I secured the pump and raised it ~2" on a footer board to be more inline with the reservoir output. With a bit of spare aluminum sheeting and some foil tape, I made a covering that should prevent any accidental etoh from directly entering the motor.

I need to properly secure my hose fittings, but it is ready to test, and I will be straight to a torture test of 4-6 hours at -78C. If it is going to break/fail, I want it to happen sooner than later.

View Image

View Image

How pump motor cooled? If it is a TEFC, the cooling air isn't in contact with the electrical.

Hey GW. Not sure how it is technically cooled, but I can see lots of copper through wide slits along the back, and there is a fan at the very end to blow heat away from unit.

I did do some testing over the weekend, and it was not a success, but the pump did not fail (yet). The simple answer is that this pump is a bitch to prime. I had etoh with dry ice chilled down to -75C, but it simply would not prime. It would cycle 10-20ml every time that I turned pump on, but that its, and it would bubble after shut off indicating not being primed. The -75C temps did not seem to impact pump versus -50C.

My solution is to raise the reservoir around ~18 inches and really create some pressure that will force any trapped air to clear pump and thus prime. Need to be confident in my fittings to avoid leaking. Will pick up more dry ice and test tomorrow.

I did do some testing over the weekend, and it was not a success, but the pump did not fail (yet). The simple answer is that this pump is a bitch to prime. I had etoh with dry ice chilled down to -75C, but it simply would not prime. It would cycle 10-20ml every time that I turned pump on, but that its, and it would bubble after shut off indicating not being primed. The -75C temps did not seem to impact pump versus -50C.

My solution is to raise the reservoir around ~18 inches and really create some pressure that will force any trapped air to clear pump and thus prime. Need to be confident in my fittings to avoid leaking. Will pick up more dry ice and test tomorrow.

Hey GW. Not sure how it is technically cooled, but I can see lots of copper through wide slits along the back, and there is a fan at the very end to blow heat away from unit.

I did do some testing over the weekend, and it was not a success, but the pump did not fail (yet). The simple answer is that this pump is a bitch to prime. I had etoh with dry ice chilled down to -75C, but it simply would not prime. It would cycle 10-20ml every time that I turned pump on, but that its, and it would bubble after shut off indicating not being primed. The -75C temps did not seem to impact pump versus -50C.

My solution is to raise the reservoir around ~18 inches and really create some pressure that will force any trapped air to clear pump and thus prime. Need to be confident in my fittings to avoid leaking. Will pick up more dry ice and test tomorrow.

If you can see into the pump windings, it isn't a Totally Enclosed Fan Cooled (TEFC) motor. That is what the one pictured appeared to be. They have fins on the outside of the motor and fan is on the back end of the shaft, outside the motor, blowing air down the fins.

If you set your reservoir higher and your pump low, you can increase the head pressure on your flooded section pump.

HashoftheTitans

Member

Hey GW. Not sure how it is technically cooled, but I can see lots of copper through wide slits along the back, and there is a fan at the very end to blow heat away from unit.

I did do some testing over the weekend, and it was not a success, but the pump did not fail (yet). The simple answer is that this pump is a bitch to prime. I had etoh with dry ice chilled down to -75C, but it simply would not prime. It would cycle 10-20ml every time that I turned pump on, but that its, and it would bubble after shut off indicating not being primed. The -75C temps did not seem to impact pump versus -50C.

My solution is to raise the reservoir around ~18 inches and really create some pressure that will force any trapped air to clear pump and thus prime. Need to be confident in my fittings to avoid leaking. Will pick up more dry ice and test tomorrow.

Good luck getting it to prime when the alcohol is carbonated. The CO2 bubbles will make it next to impossible to prime. I use a chugger pump to push ethanol through a coil submerged in dry ice and alcohol. It takes longer to get down to temperature but it keeps those pesky bubbles out of my coolant.

Good luck getting it to prime when the alcohol is carbonated. The CO2 bubbles will make it next to impossible to prime. I use a chugger pump to push ethanol through a coil submerged in dry ice and alcohol. It takes longer to get down to temperature but it keeps those pesky bubbles out of my coolant.

Now that makes some sense about the co2 bubbles. Will try to see if additional head pressure can overcome it. Thanks.

HashoftheTitans

Member

Now that makes some sense about the co2 bubbles. Will try to see if additional head pressure can overcome it. Thanks.

Put a lid on whatever vessel you are using to mix the dry ice and alcohol, and the CO2 will give you whatever pressure you need. However, that is only good for filling your column, not continuously recirculating, which you need to get down to temperature. Trust me on this one. All you need is a 1/2" x 50' coil, a chugger max pump, igloo drink cooler, and dry ice. This will get a 6" x 48" jacketed column down to -40 easily.

Good luck getting it to prime when the alcohol is carbonated. The CO2 bubbles will make it next to impossible to prime. I use a chugger pump to push ethanol through a coil submerged in dry ice and alcohol. It takes longer to get down to temperature but it keeps those pesky bubbles out of my coolant.

+10 for HashoftheTitans on this comment! It is indeed the c02 bubbles that cause the issue with the chugger pumps, and not temps or viscosity. I raised my reservoir about 15 inches and it gravity primed instantly by flushing out the air. I had the pump running and as soon as I added the dry ice, it began sputtering. Raising the pump had a significant impact, as even with the co2 bubbles at ~-70C with 3 foot head, the pump put out a constant sputter (previously it would sputter at the very beginning and then stop).

My application is quite different then yours, in that I need a smaller amount coolant to be as cold as possible (for glass coiled condensers), instead of a large volume for bulk heat transfer. There are quite a few ways to accomplish my objective by tweaking the parts that I have. I could add a coil or another 2L reservoir that sits inside my existing 6L, which would be surrounded by dry ice/etoh but only pure etoh in 2L with no c02 bubbles.

Put a lid on whatever vessel you are using to mix the dry ice and alcohol, and the CO2 will give you whatever pressure you need. However, that is only good for filling your column, not continuously recirculating, which you need to get down to temperature. Trust me on this one. All you need is a 1/2" x 50' coil, a chugger max pump, igloo drink cooler, and dry ice. This will get a 6" x 48" jacketed column down to -40 easily.

Your comments on pressure had me thinking. I could very easily just use some glassware that have - a heavy wall boiling flask with long stem dual 10mm take off adapter submerged in dry ice/etoh. Boiling flask would be full of pure etoh and the pump would pull from the bottom of the flask via the long stem. Take off adapter would be secured to flask with stainless clamp. Would this closed loop setup cause back pressure to help force the fluid to the pump? Would the pressure be too much for the glassware? Thanks for your input!

I decided to do a bit of re-engineering. I ordered some parts, including fittings, bendable copper tubing and a stainless bain marie. I am going to shape my own coil to fit in my reservoir, and bain marie will sit in center of reservoir surrounded by dry ice and etoh. Coil will start at my top bulkhead and gravity feed down to bottom of bain marie. An output on the other side of bain marie will connect to my existing lower bulkhead and go straight to pump. Logic is that the coolant will pre-chill in coil and get as close to -78C as possible at the pump head. This setup will hold ~1L of pure etoh that will not come in contact with any dry ice. More soon...

I have my coil shaped and all the new parts and fittings. Time to get her put together and tested.