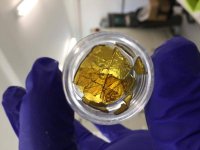

Ahhhh ok. When I viewed the bud under the microscope, I definitely saw trichome matter--stalks and some heads--but it seemed most heads were gone but some still definitely thereIt definitely sounds dry then if it crumbles. You really just might be going too cold. Start it out of -86C and then place outside the freezer and let the temps rise some to around -50C using a thermocouple to measure.

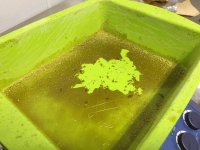

I have done quite a few ethanol extractions using nothing but trichomes collected from dry ice hash. Most of the trichome matter remains after the ethanol wash, as ethanol only interacts with some of the organic matter that composes the trichome head and stalks.

maybe 70% were gone.

Also, I also have a -30 C freezer as well. Maybe I should just keep my ethanol, filters, and tools and bud in the -86C freezer and once I begin the wash process, move the bucket (with ethanol and bud) to the -30 C freezer for the duration of the process. What do you think?

Is there a limit, temperature wise, on the solvent's ability to encapsulate solutes? I think I the -86 C could very well be too cold. I usually see folks perform this method from -50C to 0C. I imagine if the solvent is too cold, there isn't enough kinetic energy in the solvent molecules to effectively solvate compounds.

Thanks for all the feedback!