It really comes down to cost. Because we've gotten system prices to a much more attainable level, it makes more sense to run multiple systems versus one big system. Handling too much oil at once might introduce more chance of errors unless we switch to a different purge method

Or one big multi column system that can be programmed to think like what ever sized system the job demands.

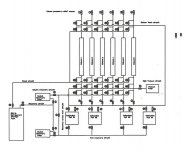

You can tell the control logic to run 2" X 12" column one at these parameters and deposit it in pot A, 3" X 36" column two to run at different parameters and deposit in pot B, 4" columns three, four, and five to run at identical parameters and dump into pot C, and 4" X 24" column six to follow yet another process path and deposit in pot D.

Pot size, temperature control and pumping capacity are the three primary control variables. Sometimes improving one, makes changes necessary in the other parameters to compensate.

IE: As the column diameter becomes larger, the time to scavenge the butane soaked into the plant material increases geometrically, because of the amount of refrigeration produced, which slows down the evaporation rates.

Ah, ha, heat the column! Worked slick, and cut 30 minutes cycle time off of the dual 4" X 24" columned Mk V, but also changed the nature of the material in the lower pot, which some of the processes go to great lengths to keep at subzero temperatures during most of the extraction.

Ergo, we now recover the columns on both the Mk IV and V separate from the lower tank, and it can even be done with a dedicated stand alone column pumping system such as on the Mk VI, or by sharing pumps with the tank, but combining the recovery streams after the pot. See attached schematic:

Good point on larger oil batches requiring different handling! I see that as possibly the next area of significant change.

We are at the practical limits of sanitary spool lower ends, because of lid deflection, and weight. Not a problem using an overhead crane, but then we move to the next level.

Clearly we can design and build anything we want, but before just making things bigger, I believe it is time to critically look at the process and question each and every component.

Although a hardy lad, or sturdy woman can handle a 10" Mk IV, it is easier when cart mounted, and handling a Mk V without cart mounting it, is asking for an injury.

Just a 12" pot is manageable, but more than you can ask employees to lift on an ongoing basis without lift assistance.

We have also reached the point that much of the processing is done subzero to produce shatters and waxes for vaporizing, and we are searching for ways to retain more of the monoterpenes, yet be relatively free of waxes.

With a Terpenator style system, propane is an option, as long as the rest of the system supports its use. Way easier to purge with a boiling point of -42°C (-43.6°F), without losing monoterpenes.

With a Terpenator style system, you can also extract with subzero solvents, so as to not pick up plant waxes in the first place, so I predict changes in the way we control butane temperature at injection.

A growing number of folks building Terpenator style systems around the world, and I predict with that many keen minds involved, the speed of evolution will increase dramatically.

Since there is already a split on whether it is better to remove the plant waxes afterward using single solvent de-waxing techniques, or just not pick them up in the first place, I see evolution there too. Easy enough to chill the mixture even more once it has been dumped, and vent it into another tank, through a filtration cartridge to remove any plant waxes that precipitate out.

Sooooo, where will all this cooling capacity come from? Working on that and have engaged the keen alleged mind of a professional brother in the cryogenic gas and equipment field, to see what insight he can add, between program managing gas recovery plant installations.

Liquid nitrogen is one possibility. Relatively cheap, being 78% of the atmosphere and easy to obtain by simple air reduction, it is used as the refrigerant in exotic gas recovery systems, to drop their temperatures low enough to fractionate.

Hee, hee, hee, awhoooooooooooooooooooooooooooooo!!!!!!!!!!1 What a fun way to spend retirement!

Attachments

Last edited: