-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Vacuum Purging Chamber

- Thread starter Gray Wolf

- Start date

Hey GW, I don't want to sound completely ignorant, but I've never been a hash oil guy. Always hated all the ways to smoke oil. Of course I haven't used a good oil rig/skillet bong.

Anyway, are you trying to purge residual butane from the oil? and why? Don't you smoke a lot more butane than any possible residue when lighting the dab with a butane lighter?

Or is there another purpose?

Anyway, are you trying to purge residual butane from the oil? and why? Don't you smoke a lot more butane than any possible residue when lighting the dab with a butane lighter?

Or is there another purpose?

The Thomas Performance Parts chamber is holding up fine, but the Best Value Vacs look to me to be a slicker design.

Sky would you go for the shattervac (1/2" poly carbonate 5gal) or regular BVV (1" Thick acrylic 5gal)?

I am considering getting a new chamber and heating element, I think the poly is good so it can be cleaned with iso but its kind of thin no?

My other option is to just get the 10 gal lid 14.25" diameter (1" thick acrylic) and a more shallow, but wider 6mm thick aluminum pot online elsewhere.

thoughts?

Hey GW, I don't want to sound completely ignorant, but I've never been a hash oil guy. Always hated all the ways to smoke oil. Of course I haven't used a good oil rig/skillet bong.

Anyway, are you trying to purge residual butane from the oil? and why? Don't you smoke a lot more butane than any possible residue when lighting the dab with a butane lighter?

Or is there another purpose?

I always recommend vaporizing rather than combusting oil, because of some of the carcinogenic byproducts from pyrolysis.

We use heat and vacuum to remove the butane to below levels of sensory detection and health concerns.

Butane has low toxicity, so the residual amount in even most badly purged oil is not a grave concern at the dosage levels you are exposed to, but it does add a butyl rubber taste.

Sky would you go for the shattervac (1/2" poly carbonate 5gal) or regular BVV (1" Thick acrylic 5gal)?

I am considering getting a new chamber and heating element, I think the poly is good so it can be cleaned with iso but its kind of thin no?

My other option is to just get the 10 gal lid 14.25" diameter (1" thick acrylic) and a more shallow, but wider 6mm thick aluminum pot online elsewhere.

thoughts?

I would go with the poly carbonate lid or something by Thomas Performance. As far as I'm aware, Acrylic is hard to clean (w/ alcohol), silicone gaskets wear away and are not that resistant to butane, and stainless steel implodes more than aluminum.

Sky would you go for the shattervac (1/2" poly carbonate 5gal) or regular BVV (1" Thick acrylic 5gal)?

I am considering getting a new chamber and heating element, I think the poly is good so it can be cleaned with iso but its kind of thin no?

My other option is to just get the 10 gal lid 14.25" diameter (1" thick acrylic) and a more shallow, but wider 6mm thick aluminum pot online elsewhere.

thoughts?

I'm still waiting for word of half inch poly breaking, until then, all I can say is mine's fine and it's still spooky when it flexes.

I'm still waiting for word of half inch poly breaking, until then, all I can say is mine's fine and it's still spooky when it flexes.

right on, i think im going with the 10 gal lid 1" acrylic and a 6mm thick sauce pot that is 13.6" in diameter and about 9.25" deep...Now how the heck do i find a heating mat for this lol.

I'm still waiting for word of half inch poly breaking, until then, all I can say is mine's fine and it's still spooky when it flexes.

While strong enough, high cyclic fatigue has it way with the thinner lids eventually. You should start to develop observable stress cracks first.

Calculating stress at the extreme fiber and deflection of Polycarbonate vacuum chamber lids lids

The formulas for calculating stress at the extreme fiber and deflection for a simply supported flat circular plate from the Thirteenth addition of the Machinery Handbook are as follows:

1.0 Assume:

S= 0.39W

t2

d= 0.221 W R2

Et3

Where:

S = Stress at the extreme fiber

T= Ultimate Tensile of Polycarbonate =9,500 psi

p= Pressure in psi = 14.7 psia atmospheric pressure

W= Total load on plate= p X area = 4618 lbs

t= Plate thickness= 2″

d= Deflection

R= Radius of plate= 1/2Diameter = 10″

E= Modulus of elasticity = 375,000 psi

D= Diameter of pot= 20″

Mechanical properties taken from: http://www.boedeker.com/polyc_p.htm

2.0 Therefore:

d= 0.221 X 4618 lbs X 100 = .034″ deflection on a 2″ plate

375,000 psi X 8

s= 0.39 X 4618 lbs = 450 psi

4

The formulas for calculating stress at the extreme fiber and deflection for a simply supported flat circular plate from the Thirteenth addition of the Machinery Handbook are as follows:

1.0 Assume:

S= 0.39W

t2

d= 0.221 W R2

Et3

Where:

S = Stress at the extreme fiber

T= Ultimate Tensile of Polycarbonate =9,500 psi

p= Pressure in psi = 14.7 psia atmospheric pressure

W= Total load on plate= p X area = 4618 lbs

t= Plate thickness= 2″

d= Deflection

R= Radius of plate= 1/2Diameter = 10″

E= Modulus of elasticity = 375,000 psi

D= Diameter of pot= 20″

Mechanical properties taken from: http://www.boedeker.com/polyc_p.htm

2.0 Therefore:

d= 0.221 X 4618 lbs X 100 = .034″ deflection on a 2″ plate

375,000 psi X 8

s= 0.39 X 4618 lbs = 450 psi

4

right on, i think im going with the 10 gal lid 1" acrylic and a 6mm thick sauce pot that is 13.6" in diameter and about 9.25" deep...Now how the heck do i find a heating mat for this lol.

Silicone heater/PID controller packages from Best Value Vacs, they took my work with my blessings...

http://bestvaluevacs.com/heatpad.html

Was just on best value vacs site.......what are your guys thoughts on the acrylic chambers they have? I'm small time and don't have the money to dump on a vac oven. I'm asking about the acrylic chamber because of ease of use with the large non-stick oil pads I use(like the size of a piece of printer paper). The metal stock pots aren't out of the question for me......I just like the looks of a rectangle vac container, as I use similar ones that came with a foodsaver vac system for sealing food, etc. .

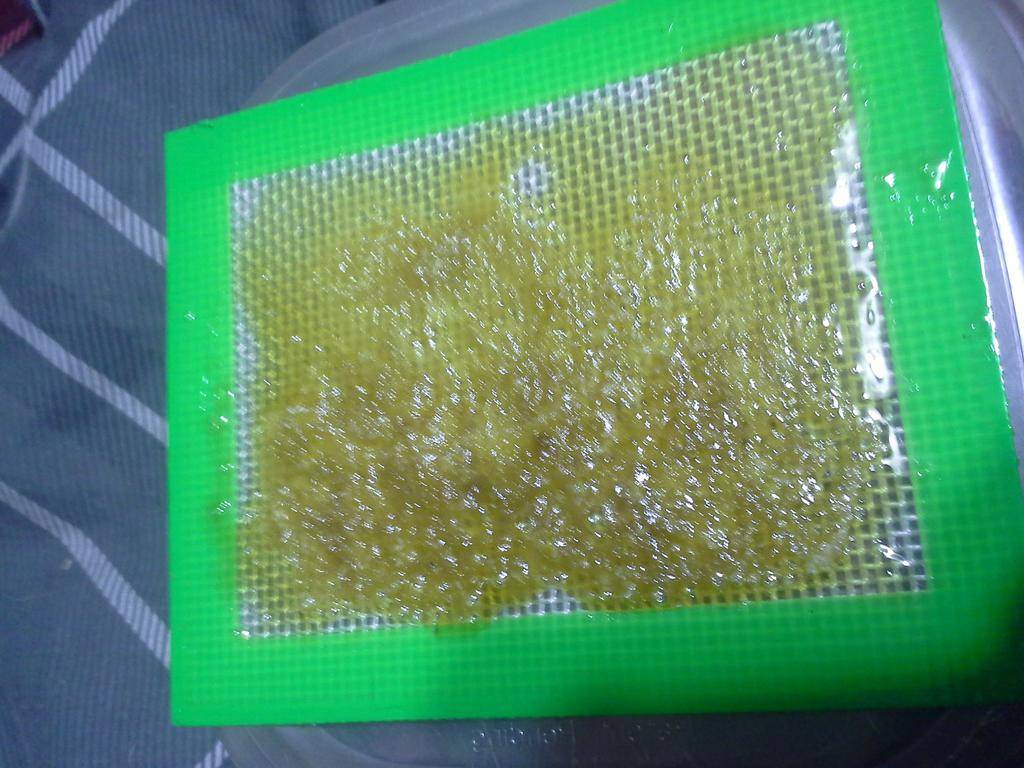

Right now I use a seedling heat mat, in a room that stays between 75-80 degrees. I usually pull a vac.....let it sit for 20-30 mins, release vac, stir bho, spread it thin again, then vac, and leave under vac for 24 hrs. I have made shatter once, and it was obviously by pure accident. But that is my goal........to be able to make shatter every time. the question about the chamber pertains to my thought process that the vac container somehow matters in this process. Any thought, comments, help is appreciated. here's some pics of one of my latest runs.

Right now I use a seedling heat mat, in a room that stays between 75-80 degrees. I usually pull a vac.....let it sit for 20-30 mins, release vac, stir bho, spread it thin again, then vac, and leave under vac for 24 hrs. I have made shatter once, and it was obviously by pure accident. But that is my goal........to be able to make shatter every time. the question about the chamber pertains to my thought process that the vac container somehow matters in this process. Any thought, comments, help is appreciated. here's some pics of one of my latest runs.

Silicone heater/PID controller packages from Best Value Vacs, they took my work with my blessings...

http://bestvaluevacs.com/heatpad.html

Son of a bitch, I just DIY'd this set-up myself...

Quite a cost effective solution!! I would highly recommend at least checking this out. What kind of relay does that thermoregulator use?

Son of a bitch, I just DIY'd this set-up myself...

Quite a cost effective solution!! I would highly recommend at least checking this out. What kind of relay does that thermoregulator use?

It may not even be a full PID controller... and it may click, click, click if it uses a mechanical relay, but if they're getting decent regulation so what? Also the internal parameters of a full PID controller can be a pain to set up until you get familiar the menu...

If you guys get these and they suck for any reason, please post up and I'll hit up Best Value Vacs with the feedback.

It may not even be a full PID controller... and it may click, click, click if it uses a mechanical relay, but if they're getting decent regulation so what? Also the internal parameters of a full PID controller can be a pain to set up until you get familiar the menu...

If you guys get these and they suck for any reason, please post up and I'll hit up Best Value Vacs with the feedback.

Just got mine, works quite well, I put a towel between it & the counter. The temp control set at 105 keeps the patty at 109.

So much better then a skillet.

BrainChild

Member

I was trying to think of a way to use multiple racks in a chamber, like in a vac oven. I know just stacking racks alone wouldn't really work because each rack would be a different temp. I was imagining one of the silicone heating mats but instead of a mat, make a "sleeve" that could fit over the entire stock pot, heating the bottom and sides. Would heating the outside walls of the chamber along with the bottom would make enough radiant heat to even out the temps throughout the chamber?

#stonedMacGyver

#stonedMacGyver

I was trying to think of a way to use multiple racks in a chamber, like in a vac oven. I know just stacking racks alone wouldn't really work because each rack would be a different temp. I was imagining one of the silicone heating mats but instead of a mat, make a "sleeve" that could fit over the entire stock pot, heating the bottom and sides. Would heating the outside walls of the chamber along with the bottom would make enough radiant heat to even out the temps throughout the chamber?

#stonedMacGyver

Radiant heat is slow and uneven, so you might consider sticking a heat sink, like a marble slab in the chamber, to soak up the radiant energy and deliver it to the paddy in the form of conducted heat.

Im thinking of having a few simple metal chambers built, what are the vac ovens from china constructed like? What type of metal and thicknesses are their oven chambers?

I like the idea of having them run the lengths of some of my counter tops, ideally 18"H x 24"W x 60"L, only one shelf, with four top and side 12"x12"x1" acrylic viewing windows.

Thanks!

I like the idea of having them run the lengths of some of my counter tops, ideally 18"H x 24"W x 60"L, only one shelf, with four top and side 12"x12"x1" acrylic viewing windows.

Thanks!