great brozini

Active member

Dry sifted, that pure gold, 99%+ heads... It's the essence, as some might say.

First off, shout out to DSW, mendo, and EE, for the info they've posted to the forums. My interpretation here is based on things they've posted in the past regarding their techniques for producing the highest quality. So if you haven't go click that 'Hashish' link up at the top of the page, do it and go read their threads first. From there is where I draw the principles and methods for my interpretation on separating resin. So thank you gentlemen....

So now that you have read, I first took on DSW's method and produced the finest resin I've ever produced, smoked, seen, etc. After a few times, I was a pro it seemed (speaks to the ease of the process, not my skills), but noticed several issues during the process.

- The inevitable static cling that holds contaminants to the screen (both the top and bottom sides) as a result of rubbing plant material and cleaning the screen with fabric. I use aluminum screens, and these seem to hold a bit more static, so that must be dealt with...

- Unacceptable loss to the environment. Needing to transfer plant material off the tops of screens, after each run is not only time consuming, but I noticed small amounts of resin would be lost during these transfers. Another issue that must be addressed.

- Finally, large batches were hard to do and time consuming with all the cleaning, so that must be fast tracked...

Looking for a solution, I came upon mendo and Ester E's threads which used a tumbler. I believe that is where I came upon my stainless mesh of 110lpi used in my tumbler. Now if only I could combine the two, to make a quicker, more efficient, but just as pure product.

Taking the principals of DSW's tek (a second screen which catches stalks as they fall and turn horizontially, minimizing vibrations to keep the contaminants out) I began to design a cheap, hand cranked tumbler... So here is the tumbler, and my process... First and most important, the material must be bone dry!

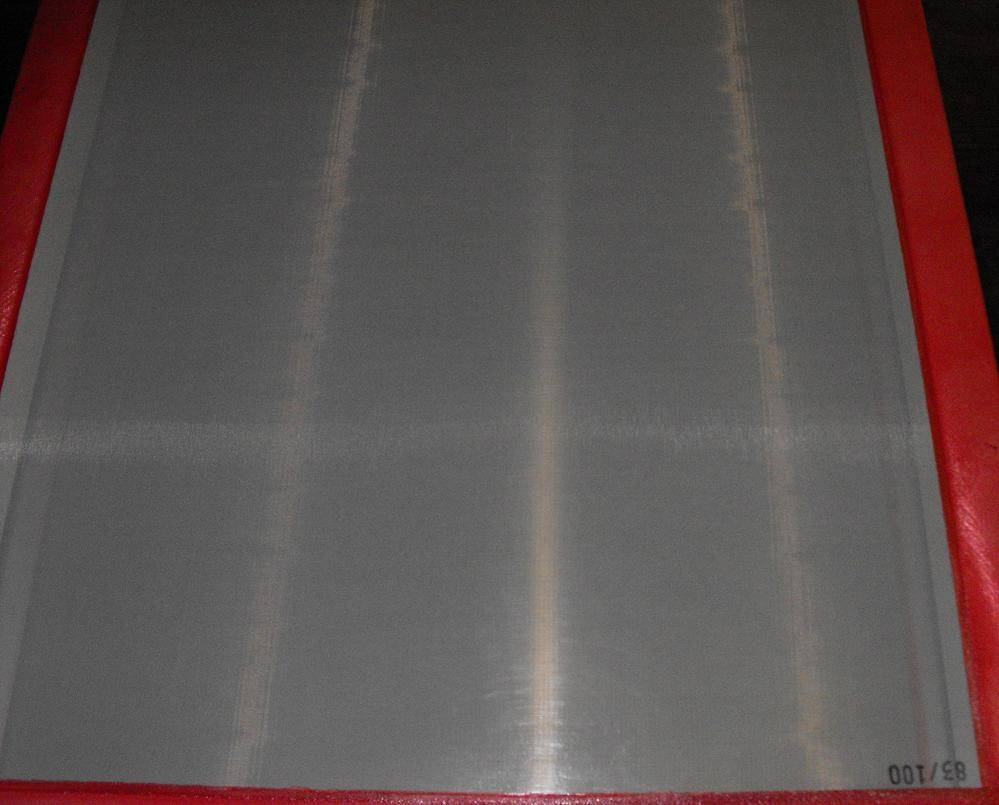

Get your flat screen, I use an 83lpi, because it was the finest, large (total area) screen I had on hand. It is 20" x 24"...

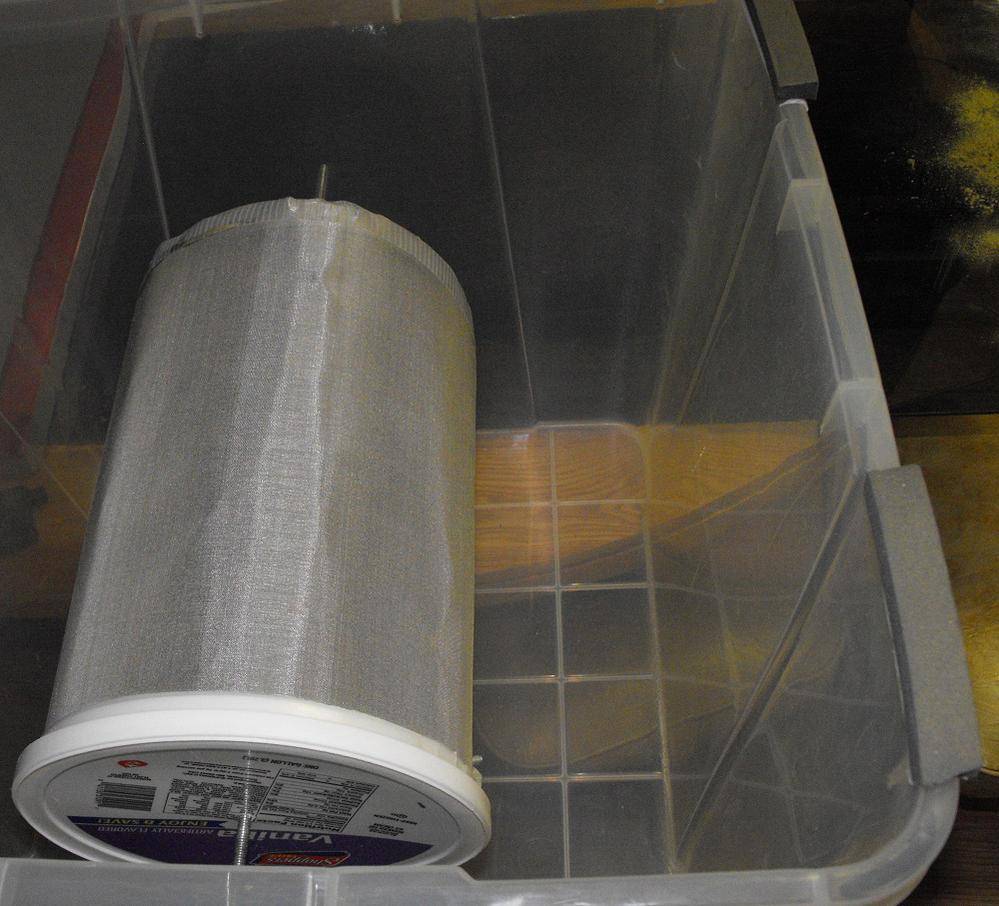

Here is the completed tumbler and enclosure, before I start talking specifics it is nice to have an image in your head.

I used a ice cream container cut to size, 2’ threaded rod, a piece of 110 stainless steel mesh, a few nuts/bolts and a little glue/tape. Cheap and functional was the intention.

The ice cream container is used for the two ends with the SS mesh in between, creating a cylinder with a removable top. The threaded rod is used as an axle and placed through the center of the two container ends with two nuts on each side of the bottom to hold the tumbler in place along the threaded rod. The two nuts on each side will be strong enough so that we can hand crank the tumbler using just this one rod for support and rotation. The mesh is connected to the ice cream ends with double sided tape, and a little gorilla glue. The SS mesh is connected to itself using 3 bolts, followed by a bit of gorilla glue, and finally a little tape. The tape has since been removed with the screws and glue plenty strong to hold it together along the length of the tumbler...

First off, shout out to DSW, mendo, and EE, for the info they've posted to the forums. My interpretation here is based on things they've posted in the past regarding their techniques for producing the highest quality. So if you haven't go click that 'Hashish' link up at the top of the page, do it and go read their threads first. From there is where I draw the principles and methods for my interpretation on separating resin. So thank you gentlemen....

So now that you have read, I first took on DSW's method and produced the finest resin I've ever produced, smoked, seen, etc. After a few times, I was a pro it seemed (speaks to the ease of the process, not my skills), but noticed several issues during the process.

- The inevitable static cling that holds contaminants to the screen (both the top and bottom sides) as a result of rubbing plant material and cleaning the screen with fabric. I use aluminum screens, and these seem to hold a bit more static, so that must be dealt with...

- Unacceptable loss to the environment. Needing to transfer plant material off the tops of screens, after each run is not only time consuming, but I noticed small amounts of resin would be lost during these transfers. Another issue that must be addressed.

- Finally, large batches were hard to do and time consuming with all the cleaning, so that must be fast tracked...

Looking for a solution, I came upon mendo and Ester E's threads which used a tumbler. I believe that is where I came upon my stainless mesh of 110lpi used in my tumbler. Now if only I could combine the two, to make a quicker, more efficient, but just as pure product.

Taking the principals of DSW's tek (a second screen which catches stalks as they fall and turn horizontially, minimizing vibrations to keep the contaminants out) I began to design a cheap, hand cranked tumbler... So here is the tumbler, and my process... First and most important, the material must be bone dry!

Get your flat screen, I use an 83lpi, because it was the finest, large (total area) screen I had on hand. It is 20" x 24"...

Here is the completed tumbler and enclosure, before I start talking specifics it is nice to have an image in your head.

I used a ice cream container cut to size, 2’ threaded rod, a piece of 110 stainless steel mesh, a few nuts/bolts and a little glue/tape. Cheap and functional was the intention.

The ice cream container is used for the two ends with the SS mesh in between, creating a cylinder with a removable top. The threaded rod is used as an axle and placed through the center of the two container ends with two nuts on each side of the bottom to hold the tumbler in place along the threaded rod. The two nuts on each side will be strong enough so that we can hand crank the tumbler using just this one rod for support and rotation. The mesh is connected to the ice cream ends with double sided tape, and a little gorilla glue. The SS mesh is connected to itself using 3 bolts, followed by a bit of gorilla glue, and finally a little tape. The tape has since been removed with the screws and glue plenty strong to hold it together along the length of the tumbler...

Last edited: