luvdemshrooms

Member

Between the spare reflectors/hood I have on hand and that "other" CXA3050 thread... I was inspired. This unit is for flowering so 2700K LED's were used. Alas, the CRI is 80 as none better was to be found.

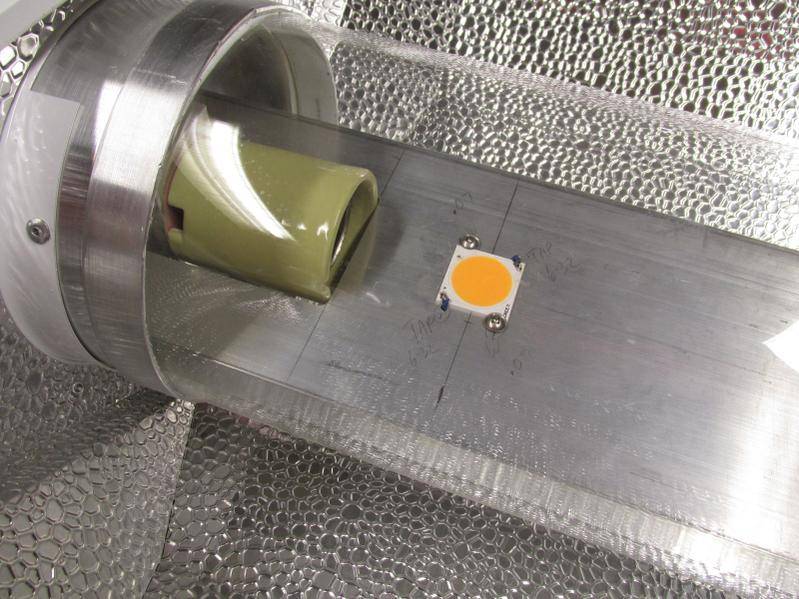

I bought the 4.9" X 26" heat sink from heatsinkusa and proceeded to mill. This is the result:

I drilled and tapped some 6-32 holes and added some .089 holes to run my wires through. A thin film of heat sink grease and some 6-32 truss head stainless screws... Edit: Do NOT mount your LED's this way. They fail prematurely. I was cheap and didn't buy the mounts. Do not make the same mistake.

No mods were made to the hood so it can be used for it's original purpose should I desire.

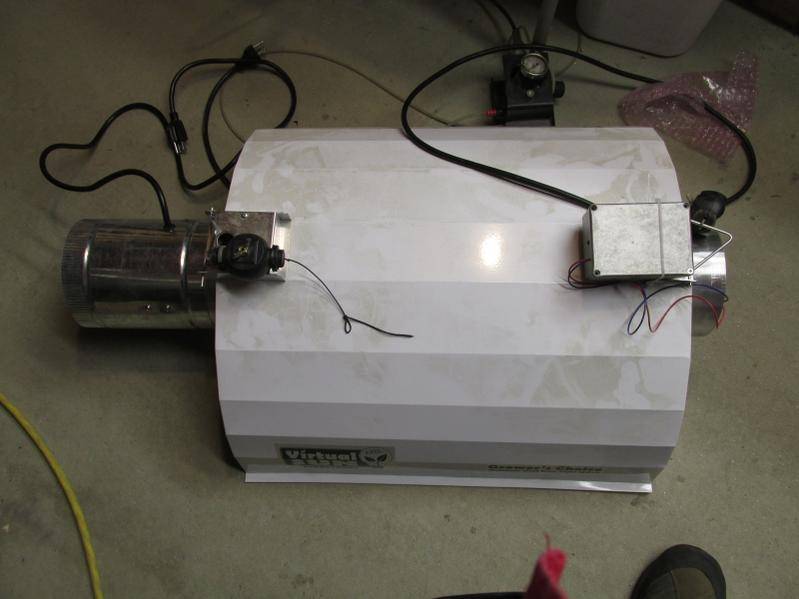

Using a hand built driver I'm running 1.6A through the LED's. The temperature of the LED runs between 37 - 39c with a400cfm 250cfm fan blowing. Using my crappy old light meter (lux only) showed that:

1. 600w HPS was hitting 1000 lux at 2 feet.

2. My new LED unit hits 1500.

The meter may not give accurate readings as I haven't had it checked but it was used for comparison only.

I was concerned that the tube would interfere with the light output, but when measured at the same (yet unrecorded) distance on the bench there was a roughly 10% improvement when the unit is inside the tube. I chalk that up to the reflector.

Current draw? 220 watts.

I bought the 4.9" X 26" heat sink from heatsinkusa and proceeded to mill. This is the result:

I drilled and tapped some 6-32 holes and added some .089 holes to run my wires through. A thin film of heat sink grease and some 6-32 truss head stainless screws... Edit: Do NOT mount your LED's this way. They fail prematurely. I was cheap and didn't buy the mounts. Do not make the same mistake.

No mods were made to the hood so it can be used for it's original purpose should I desire.

Using a hand built driver I'm running 1.6A through the LED's. The temperature of the LED runs between 37 - 39c with a

1. 600w HPS was hitting 1000 lux at 2 feet.

2. My new LED unit hits 1500.

The meter may not give accurate readings as I haven't had it checked but it was used for comparison only.

I was concerned that the tube would interfere with the light output, but when measured at the same (yet unrecorded) distance on the bench there was a roughly 10% improvement when the unit is inside the tube. I chalk that up to the reflector.

Current draw? 220 watts.

Last edited: