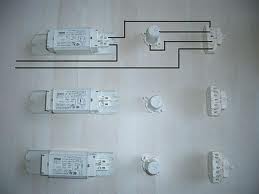

i got my stuffs in today

10 ballasts and lights and all misc stuff to wire it all

5 x 2700 and 5 x 6000 36 watts.

i will be mounting those into my pc, and hoping to fit 3-5 of them in there.

tho i will have to keep an eye on the temps as im sure these will generate some heat inside such a small space

The ballasts ill be mounted to the metal of the case and the lamps below that .

But i figured i need some form of divider to split up the space with the ballasts to

make the temperatures easier to manage if i end up fitting 5 instead of 3.

i was thinking of using wood as a divider, and mount the 2G11's on there.

tho I'm not sure if the heat produced by the light, especially near the base of the light

is going to be a problem for a wooden plate.

Ill be using this to guide me through the wiring:

These happen to be similar to the parts i ordered so i don't expect any problems there

Yay... Soon ill be ready for the 1st test grow

10 ballasts and lights and all misc stuff to wire it all

5 x 2700 and 5 x 6000 36 watts.

i will be mounting those into my pc, and hoping to fit 3-5 of them in there.

tho i will have to keep an eye on the temps as im sure these will generate some heat inside such a small space

The ballasts ill be mounted to the metal of the case and the lamps below that .

But i figured i need some form of divider to split up the space with the ballasts to

make the temperatures easier to manage if i end up fitting 5 instead of 3.

i was thinking of using wood as a divider, and mount the 2G11's on there.

tho I'm not sure if the heat produced by the light, especially near the base of the light

is going to be a problem for a wooden plate.

Ill be using this to guide me through the wiring:

These happen to be similar to the parts i ordered so i don't expect any problems there

Yay... Soon ill be ready for the 1st test grow

.

.