-

Happy Birthday ICMag! Been 20 years since Gypsy Nirvana created the forum! We are celebrating with a 4/20 Giveaway and by launching a new Patreon tier called "420club". You can read more here.

-

Important notice: ICMag's T.O.U. has been updated. Please review it here. For your convenience, it is also available in the main forum menu, under 'Quick Links"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TheArchitect's master plan, 6k colosseum.

- Thread starter TheArchitect

- Start date

Midmichkush

Member

i ordered them in sets of 50 to residential the package really is more then manageable the black ones have a small lip and stack very compact a stack of 20 white buckets is twice as tall as a stack of 20 of the blacks.

But ok so what is your set up? I cant really see all the plumbing enough to figure it out. pressurized water goes into each bucket at the top, then there is a drain in the bottom? is the water always filled to the top then like a dwc? is there alot of turbulance inside the bucket? got a pic of its internals? air stones or waterfall anywhere inline? And hell yea i can definatly appriciate an intense hydro builder in michigan. This is my control box i have built for a dual 4000 watt dwc flower rooms on 2nd floor with res to be in the basement. (yet to complete this build whats the point with the change in dispensary laws now) plus i dont need to run dual failures as i am so new to hydro i am taking a rough learning curve. keep building the big shit! take it easy.

But ok so what is your set up? I cant really see all the plumbing enough to figure it out. pressurized water goes into each bucket at the top, then there is a drain in the bottom? is the water always filled to the top then like a dwc? is there alot of turbulance inside the bucket? got a pic of its internals? air stones or waterfall anywhere inline? And hell yea i can definatly appriciate an intense hydro builder in michigan. This is my control box i have built for a dual 4000 watt dwc flower rooms on 2nd floor with res to be in the basement. (yet to complete this build whats the point with the change in dispensary laws now) plus i dont need to run dual failures as i am so new to hydro i am taking a rough learning curve. keep building the big shit! take it easy.

Attachments

Midmichkush

Member

and yeah thanks for the advice im dropping my ec back down too 1 also. actually in my ebb and flow i just put RO in for the day and the EC is already back to .6 from reverse flowing of extra nutes outta the plant i assume. yikes. i need to listen to the pros. Ill change it again and set it to 1 tomorrow

'ohh and u should check out usplasticcorp.com next time you make a set up you can buy nice black 5 gallon pots cheaper then those home depot ones and they are in ohio

I like usplasticcorp... I just received 4 float valves from them. Got a 10% discount for ordering 4. The funny thing was though that after I received my order, I also received a funny letter thanking me for my business and letting me know that my order motivates them to do a better job or some crap like that... I spent $80? lol.. Very strange. Never received a correspondence like it.

Hey my midmich brother, got friends at central, thanks for stopping in.

The pump is a little giant 4000 gph pump http://www.pondliner.com/product/little_giant_f30-4000_wet_rotor_pump/little_giant_f-series_wet_rotor_pumps

For the price it rocks. Has no problem supplying 28 buckets.

Lol, yea all the wood was cut by hand saw(im a glutton for punishment, plus its quiet) the PVC I used plier like quick cutters.

Inside the buckets is rocking, they get enough water to exchange the entire volume more than ten times per hour. Res Temps run at ambient, so ~75f, ec is 1, humidity 50-60.

Yea, I though about ordering, but 30 5 gallon buckets is a hell of a package to a residential address, lol.

Hand saw? You are a glutton for punishment... I like to take all my measurements, and then make all of my cuts at once, so I don't have the skill saw running all day and night. Once I had a guy as Home Depot cut a bunch of 2"x2"x8' into 1' sections... lol... When I'm sawing manually... I think to myself "what if I slip and cut myself... Nobody else is here..." Anyway... Those are just my ramblings.

Waiting for

D

DHF

Hey Bro.....Yas might need ta check into a sterilizing agent for your juice since anything over 70 degrees invites pythium/root rot in recirculating fast hydro without a chiller inline....and...

Once the bottom containers are full of rootmass volume , that exchange rate per hr is gonna slow down guaranteed.....now....If rez temp`s 75 , then bet on bottom container temps bein higher inside the grow area , and or will be by the time the containers build all the roots they can before end of stretch after the flip.....

I`ve read on numerous occasions that adding EWC teas and bene`s to prevent potential root rot with elevated solution temps , but have no experience therein and cannot comment on said application.......but.....yas can`t run sterilizing agents like DM Zone along with bene`s cuz the Zone will kill the bene`s , so.....that said...

Max O2 saturation in nutrient solution is optimum between 65-69 degrees and drops drastically above that margin that in turn invites rootborn pathogens to proliferate.......anyways.....

Setup looks solid , so let`s keep it that way and dot all our I`s and cross all our T`s and bring a big Harvey on home .....Good luck and......

Peace....DHF...... ......

......

Once the bottom containers are full of rootmass volume , that exchange rate per hr is gonna slow down guaranteed.....now....If rez temp`s 75 , then bet on bottom container temps bein higher inside the grow area , and or will be by the time the containers build all the roots they can before end of stretch after the flip.....

I`ve read on numerous occasions that adding EWC teas and bene`s to prevent potential root rot with elevated solution temps , but have no experience therein and cannot comment on said application.......but.....yas can`t run sterilizing agents like DM Zone along with bene`s cuz the Zone will kill the bene`s , so.....that said...

Max O2 saturation in nutrient solution is optimum between 65-69 degrees and drops drastically above that margin that in turn invites rootborn pathogens to proliferate.......anyways.....

Setup looks solid , so let`s keep it that way and dot all our I`s and cross all our T`s and bring a big Harvey on home .....Good luck and......

Peace....DHF......

......

......But ok so what is your set up? I cant really see all the plumbing enough to figure it out. pressurized water goes into each bucket at the top, then there is a drain in the bottom? is the water always filled to the top then like a dwc? is there alot of turbulance inside the bucket? got a pic of its internals? air stones or waterfall anywhere inline? And hell yea i can definatly appriciate an intense hydro builder in michigan.

hopefully this, and any following pics will help clarify whats going on.

This is my control box i have built for a dual 4000 watt dwc flower rooms on 2nd floor with res to be in the basement. (yet to complete this build whats the point with the change in dispensary laws now) plus i dont need to run dual failures as i am so new to hydro i am taking a rough learning curve. keep building the big shit! take it easy.

thats nice right there, and i wouldnt worry about dispensaries closing(yet at least), most of that is up to local jurisdiction, so plenty are staying open with their respective cities blessings.

hydro can certainly demand a steep curve, but with some diligent study, and attention to detail, you can have it locked down(and avoid mistakes) in two or three grows, and with prior experience its that much easier, as long as your willing to change things up and roll with the punches.

i was thinking like this one less than half the price.

http://www.growonix.com/ex-series/ex1000

the one you linked to is bitchin though.

I like usplasticcorp... I just received 4 float valves from them. Got a 10% discount for ordering 4. The funny thing was though that after I received my order, I also received a funny letter thanking me for my business and letting me know that my order motivates them to do a better job or some crap like that... I spent $80? lol.. Very strange. Never received a correspondence like it.

real christian company, still family owned i think. explains the gracious customer service i guess.

Hand saw? You are a glutton for punishment... I like to take all my measurements, and then make all of my cuts at once, so I don't have the skill saw running all day and night. Once I had a guy as Home Depot cut a bunch of 2"x2"x8' into 1' sections... lol... When I'm sawing manually... I think to myself "what if I slip and cut myself... Nobody else is here..." Anyway... Those are just my ramblings.

Waiting for

hehehe, yea i thought about dumping the load of cutting off on the poor sap at the depot, but i think i needed a workout, lol.

im not terribly worried about injuries though, i have a life time of handyman experience, and i worked commercial carpentry for a few years too.

pics to come.

Hey Bro.....Yas might need ta check into a sterilizing agent for your juice since anything over 70 degrees invites pythium/root rot in recirculating fast hydro without a chiller inline....and...

Once the bottom containers are full of rootmass volume , that exchange rate per hr is gonna slow down guaranteed.....now....If rez temp`s 75 , then bet on bottom container temps bein higher inside the grow area , and or will be by the time the containers build all the roots they can before end of stretch after the flip.....

yea, the system is designed to compensate, ie the pump pulls, and pushes from and to all buckets, a 4000gph pump, inline bio-filter.

honestly, i think each bucket gets a minimum of 1-1.5 gallon per minute right now, so any loss in exchange rate should still leave me above 10 eph, at least thats the goal lol.

I`ve read on numerous occasions that adding EWC teas and bene`s to prevent potential root rot with elevated solution temps , but have no experience therein and cannot comment on said application.......but.....yas can`t run sterilizing agents like DM Zone along with bene`s cuz the Zone will kill the bene`s , so.....that said...

absolutely, beneficial bacteria do all the dirty work for me.

in the picture of the pump plumbing, you can see a shut off about two feet in front of the pump(i can take the pump out while the system is filled with water), after that it jumps up to two inch pvc and has coarse filter pad inside to catch debris, and act as an inline biofilter.

in addition to that another biofilter is going into the main res once that gets hooked up.

no sterilizers here, only for cleaning and cloning.

Max O2 saturation in nutrient solution is optimum between 65-69 degrees and drops drastically above that margin that in turn invites rootborn pathogens to proliferate.......anyways....

i used to think this to, but then i really looked into it, and the difference between 69f and 80f water temps is less than 1ppm.

now i cant say if there is a difference in results, but ive had no problem hitting 2 per light with elevated temps.

one day, i would like to do a side by side, but my instinct, and the one last bit of info i came across tells me there is not going to be a difference thats noticeable.

in the book below, best nutrient uptake in multiple crops was achieved when the solution temperature matches canopy, or leaf temp.

http://www.amazon.com/Hydroponics-Practical-Guide-Soilless-Grower/dp/0849331676/ref=pd_sim_sbs_b_1

Setup looks solid , so let`s keep it that way and dot all our I`s and cross all our T`s and bring a big Harvey on home .....Good luck and......

Peace....DHF......

thanks freds.

pics!

pics!

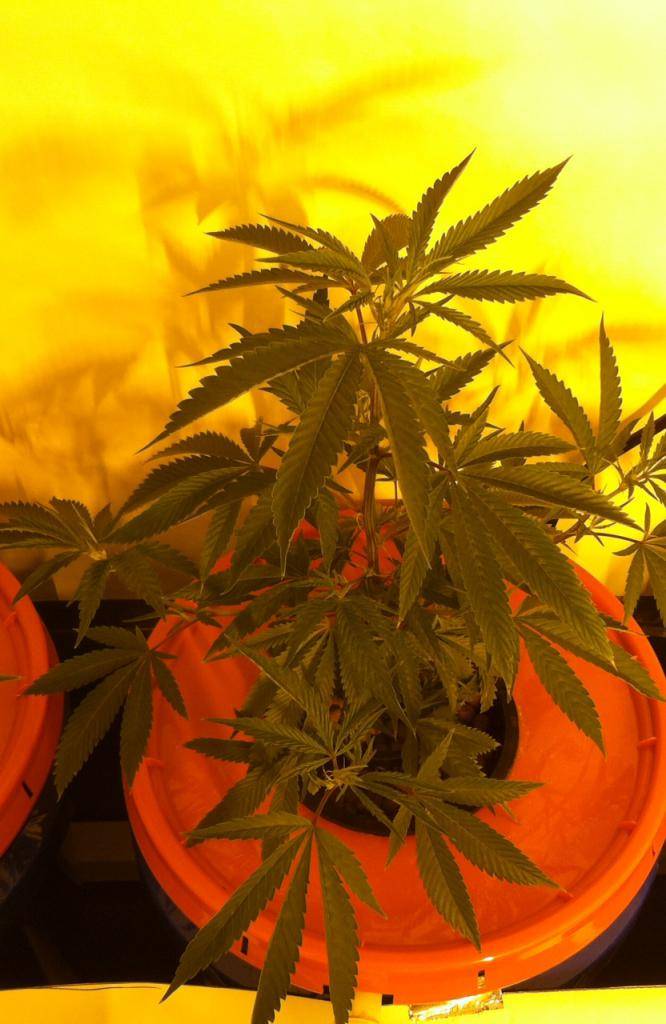

Bubbas trainwreckhaze #3, indica leaning, kushy smelling (raredankness seeds)

BTH#2, sandlewood, pepper, very sativa

Tahoe og

BTH#1 (favorite so far) classic bubba stink with sativa like internode spacing. have i found a stretchy bubba? that'd be nice

pics!

Bubbas trainwreckhaze #3, indica leaning, kushy smelling (raredankness seeds)

BTH#2, sandlewood, pepper, very sativa

Tahoe og

BTH#1 (favorite so far) classic bubba stink with sativa like internode spacing. have i found a stretchy bubba? that'd be nice

more!

more!

clones for the table in the middle.

boomers baby, some penis envy spawn bags.

more!

clones for the table in the middle.

boomers baby, some penis envy spawn bags.

where the hell have i been... great build!! i'm in

bennies ftw!!

bennies ftw!!

D

DHF

Bro.....Show us some shit........But I`ve seen countless setups keel over and die within a 24 hr period with elevated rootzone temps with seriously depleted DO from chillers takin a shit , or prolonged power outages......but.....

If you`re confident in being able to ward off rootborn pathogens with 80 degree rootzone temps in your setup , then I`m onboard 1000%.......and....

Proof`s in the pudding.....Only makes it easier for everyone else to learn and adapt to new and better methods of getting past the dreaded root rot beast in fast hydro......Respect....

Handle it my buddy.....Freds..... .....

.....

If you`re confident in being able to ward off rootborn pathogens with 80 degree rootzone temps in your setup , then I`m onboard 1000%.......and....

Proof`s in the pudding.....Only makes it easier for everyone else to learn and adapt to new and better methods of getting past the dreaded root rot beast in fast hydro......Respect....

Handle it my buddy.....Freds.....

.....

.....DHF, i totally agree with your guttural feeling.

AND, if i were to be advising someone else on their system, where i dont know all factors, like exchanges per hour, water source, co2 in the room etc, i would always advise the cautious route of lower rez temps.

that being said, ive never once ran a chiller, just let the temps go, though they never exceeded ambient, which stays under 80, and ive never had a problem.

im a firm believer most people undersize their pumps and feed/drain lines.

im using 1.5 inch drains and a 1 inch manifold feeding 1/2 inch valve controlled feed lines, and a 4000gph pump.

this is a new system though so, a live experiment we shall witness

AND, if i were to be advising someone else on their system, where i dont know all factors, like exchanges per hour, water source, co2 in the room etc, i would always advise the cautious route of lower rez temps.

that being said, ive never once ran a chiller, just let the temps go, though they never exceeded ambient, which stays under 80, and ive never had a problem.

im a firm believer most people undersize their pumps and feed/drain lines.

im using 1.5 inch drains and a 1 inch manifold feeding 1/2 inch valve controlled feed lines, and a 4000gph pump.

this is a new system though so, a live experiment we shall witness

Last edited:

D

DHF

Pullin for yas Bro.......Got nuthin but love and respect for them what tests the boundaries and push past em with success for the community.....

Just make sure yas give us a full copy of the rules so we too can grow and prosper accordingly......reason being......This screams in the face of them laws of the "limiting factors" in fast hydro , so......

Enquiring minds want the gameplan laid out so as to do the fuck away with all the bells and whistles it takes to grow fast hydro conventionally up and until now....that said....

Thanks Bro....You da man......Keep us updated......

Peace....DHF..... .....

.....

Just make sure yas give us a full copy of the rules so we too can grow and prosper accordingly......reason being......This screams in the face of them laws of the "limiting factors" in fast hydro , so......

Enquiring minds want the gameplan laid out so as to do the fuck away with all the bells and whistles it takes to grow fast hydro conventionally up and until now....that said....

Thanks Bro....You da man......Keep us updated......

Peace....DHF.....

.....

.....Pullin for yas Bro.......Got nuthin but love and respect for them what tests the boundaries and push past em with success for the community.....

Just make sure yas give us a full copy of the rules so we too can grow and prosper accordingly......reason being......This screams in the face of them laws of the "limiting factors" in fast hydro , so......

thanks, and all the rules will be laid out in my posts, and in the end, should i remember, ill collate all the pertinent info into one post.

but really, its nothing new. im not rewriting books, im just shooting for ideal parameters. ive read, countless academic studies, as well as online grow logs, and i have a dash of experience, its all being culminated here.

Enquiring minds want the gameplan laid out so as to do the fuck away with all the bells and whistles it takes to grow fast hydro conventionally up and until now....that said....

Thanks Bro....You da man......Keep us updated......

Peace....DHF..........

yes sir! lol

ill detail all i need to in order to make clear how to properly replicate results.

but the glory of this system is its simplicity(aside from initial construction)

no air pumps, no sterilants, no chiller, no headaches.

the system can be drained completely by pump, the main feed pump can be disconnected even while the system is full, and all buckets have individual flow control.

the res stays extraordinarily stable, and the plants (all 5 strains) are happy(hopefully it stays that way in flower.)

anyway thanks for getting me to post, i usually have to be asked for more detail, i assume people get it unless they ask.

so ask away folks.

Midmichkush

Member

Architect i love that set up that is bad ass and a pretty cool idea. The roots as they get longer arent getting sucked down the drain at the bottom of each bucket? it pushes h2o into the top of the bucket and sucks from the bottom at the same time but how does your res tie into the system? You should incorporate a system to take advantage of our cold winters to lower that water temp. I dont know what outside looks like there for you but perhaps even like an aluminum automotive radiator under a deck outside put inline of the high pressure side with a switching valve controlled by a thermostat? Summer it wouldnt work but during those 3 months here does anything ever work with indoor grows anyways? Oh and im also loving the fungus pics you and I are alot alike on what interests us lol.

That panorama pic is cray....

T

THriveCompany

Room looks fun to work in great job....

I'll dig up the 15g dried PE things are strong and can get intimidating in size hahahahah...

I'll dig up the 15g dried PE things are strong and can get intimidating in size hahahahah...

Last edited:

E

ekomsi

Great looking gro, can't wait to see this room in full on flower. How long until you flip the buckets?

About 1.5 weeks from now probably.