greengiraffe

New member

Hey everyone so I've been reading thread after thread trying to figure out what i need to do to build and install a sub panel in my grow room. I have gathered a pretty decent amount of information on the matter, I'm just having some problems finalizing everything, so ill fill you in with what i know, and hopefully someone can help fill in the blanks for me, so here we go.

The set up I'm trying to run is 2 600W MH lights for VEG and 1 1000W HPS for flowering. All this I figure is about 10A, I also will be running a AC unit for my intake and a inline fan for my exhaust, I plan install some form of enviormental control as well, just havent quite made up my mind yet on what type. I've seen a couple DIY thermostats but it seems that half the farmers on here are for them and the other half is against them siting easy house fire as the reason, so mabye someone can clear this matter up for me. Other than those big items I'm pretty sure everything else will be fine being ran on a single pole 20A breaker. Now that everyone is caught up to speed on what the over all finished product will have to do I have some questions for you guys starting with the Main panel.

I have a 200A main breaker panel that runs the house( see pics below), I know that i need to install a feed breaker on my main panel to run to my sub panel, and to do that I need to decide on my sub panel Amp rating, but im not sure exaclty which one to choose. I want to be able to expand later on if i choose to so i was thinking of going with a 125A load center. (preferably this one because its a good price and is expandable)

http://www.homedepot.com/Electrical...splay?langId=-1&storeId=10051&catalogId=10053

MAIN PANEL

Now with all that said and pretending this 125A unit is the one I decide to use....

QUESTION 1:

WILL I HAVE TO INSTALL A 125A 2 POLE BREAKER ON MY MAIN PANEL, OR CAN I USE A SMALLER BREAKER AS MY FEED BREAKER?

QUESTION 2:

WHAT RATED WIRE WILL I HAVE TO USE TO RUN FROM MY MAIN PANEL TO THE SUB PANEL?

QUESTION 3:(THIS ONE IS GONNA MAKE ME SOUND STUPID)

CAN I PIGTAIL INTO THE EXISTING BREAKERS ON THE PANEL OR SHOULD I INSTALL A WHOLE NEW BREAKER?

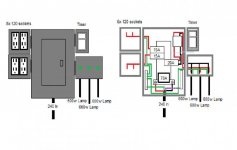

SUB PANEL DIAGRAM

OK now on to the actual sub panel itself. I have made up a rough diagram of what I hope to build. I plan to initially run 2 30A 2 pole breaker for the AC and lights, and 2 or 3 15A 1 pole breakers for everything else. I also plan to install a 30A relay that will to timed, everything else will have constant power.This is the part I'm pretty confident about because I have read threw a lot of similar DIY projects, and I'm left with only these questions:

QUESTION 1:WHAT WIRE SIZE IS REQUIRED FOR THE WIRING OF THE SUB PANEL?

QUESTION 2:I READ THAT BECAUSE THIS UNIT IS A MAIN LUG I WILL HAVE TO SEPARATE THE GROUND AND NEUTRAL AND POSSIBLY LIFT IT AWAY FROM THE PANEL, IS THIS CORRECT, AND IF NOT CAN SOMEONE PLEASE EXPLAIN THE IMPORTANCE OF DOING THIS?

QUESTION 3:I PLAN TO USE ONLY 2 120 OUTLETS AND 2 240 TO START WITH, THE 2 240 OUTLETS WILL BE WIRED TO THE 30A RELAY CAN THIS BE DONE SAFELY, DUE TO THE FACT THAT THE LOAD WILL BE LESS THAT 70% OF THE BREAKER AND RELAY, OR WILL THE PLUGS HAVE TO BE ON SEPARATE CIRCUITS?

I'm waiting on my harvest before I can purchase the remaining pieces for my control box, so its not a huge rush but I would like to have it completed and installed before I start my next crop, there is going to be overlap but I would like to make it as minimal as possible. Thanks for taking the time to read this thread any and all advise would be greatly appreciated and if I missed something please don't hesitate to tell me I would rather know then not and end up burning my house down.

HAPPY HARVEST EVERYONE!!!!!

The set up I'm trying to run is 2 600W MH lights for VEG and 1 1000W HPS for flowering. All this I figure is about 10A, I also will be running a AC unit for my intake and a inline fan for my exhaust, I plan install some form of enviormental control as well, just havent quite made up my mind yet on what type. I've seen a couple DIY thermostats but it seems that half the farmers on here are for them and the other half is against them siting easy house fire as the reason, so mabye someone can clear this matter up for me. Other than those big items I'm pretty sure everything else will be fine being ran on a single pole 20A breaker. Now that everyone is caught up to speed on what the over all finished product will have to do I have some questions for you guys starting with the Main panel.

I have a 200A main breaker panel that runs the house( see pics below), I know that i need to install a feed breaker on my main panel to run to my sub panel, and to do that I need to decide on my sub panel Amp rating, but im not sure exaclty which one to choose. I want to be able to expand later on if i choose to so i was thinking of going with a 125A load center. (preferably this one because its a good price and is expandable)

http://www.homedepot.com/Electrical...splay?langId=-1&storeId=10051&catalogId=10053

MAIN PANEL

Now with all that said and pretending this 125A unit is the one I decide to use....

QUESTION 1:

WILL I HAVE TO INSTALL A 125A 2 POLE BREAKER ON MY MAIN PANEL, OR CAN I USE A SMALLER BREAKER AS MY FEED BREAKER?

QUESTION 2:

WHAT RATED WIRE WILL I HAVE TO USE TO RUN FROM MY MAIN PANEL TO THE SUB PANEL?

QUESTION 3:(THIS ONE IS GONNA MAKE ME SOUND STUPID)

CAN I PIGTAIL INTO THE EXISTING BREAKERS ON THE PANEL OR SHOULD I INSTALL A WHOLE NEW BREAKER?

SUB PANEL DIAGRAM

OK now on to the actual sub panel itself. I have made up a rough diagram of what I hope to build. I plan to initially run 2 30A 2 pole breaker for the AC and lights, and 2 or 3 15A 1 pole breakers for everything else. I also plan to install a 30A relay that will to timed, everything else will have constant power.This is the part I'm pretty confident about because I have read threw a lot of similar DIY projects, and I'm left with only these questions:

QUESTION 1:WHAT WIRE SIZE IS REQUIRED FOR THE WIRING OF THE SUB PANEL?

QUESTION 2:I READ THAT BECAUSE THIS UNIT IS A MAIN LUG I WILL HAVE TO SEPARATE THE GROUND AND NEUTRAL AND POSSIBLY LIFT IT AWAY FROM THE PANEL, IS THIS CORRECT, AND IF NOT CAN SOMEONE PLEASE EXPLAIN THE IMPORTANCE OF DOING THIS?

QUESTION 3:I PLAN TO USE ONLY 2 120 OUTLETS AND 2 240 TO START WITH, THE 2 240 OUTLETS WILL BE WIRED TO THE 30A RELAY CAN THIS BE DONE SAFELY, DUE TO THE FACT THAT THE LOAD WILL BE LESS THAT 70% OF THE BREAKER AND RELAY, OR WILL THE PLUGS HAVE TO BE ON SEPARATE CIRCUITS?

I'm waiting on my harvest before I can purchase the remaining pieces for my control box, so its not a huge rush but I would like to have it completed and installed before I start my next crop, there is going to be overlap but I would like to make it as minimal as possible. Thanks for taking the time to read this thread any and all advise would be greatly appreciated and if I missed something please don't hesitate to tell me I would rather know then not and end up burning my house down.

HAPPY HARVEST EVERYONE!!!!!