JG's Ghost

Active member

Put this up in my Warehouse grow room thread, but am getting no response so I thought in might get more attention here.

Hey guys:

Just finishing up the wiring of the sub panel, and from there to the timers. Just want to be sure I've got this all right

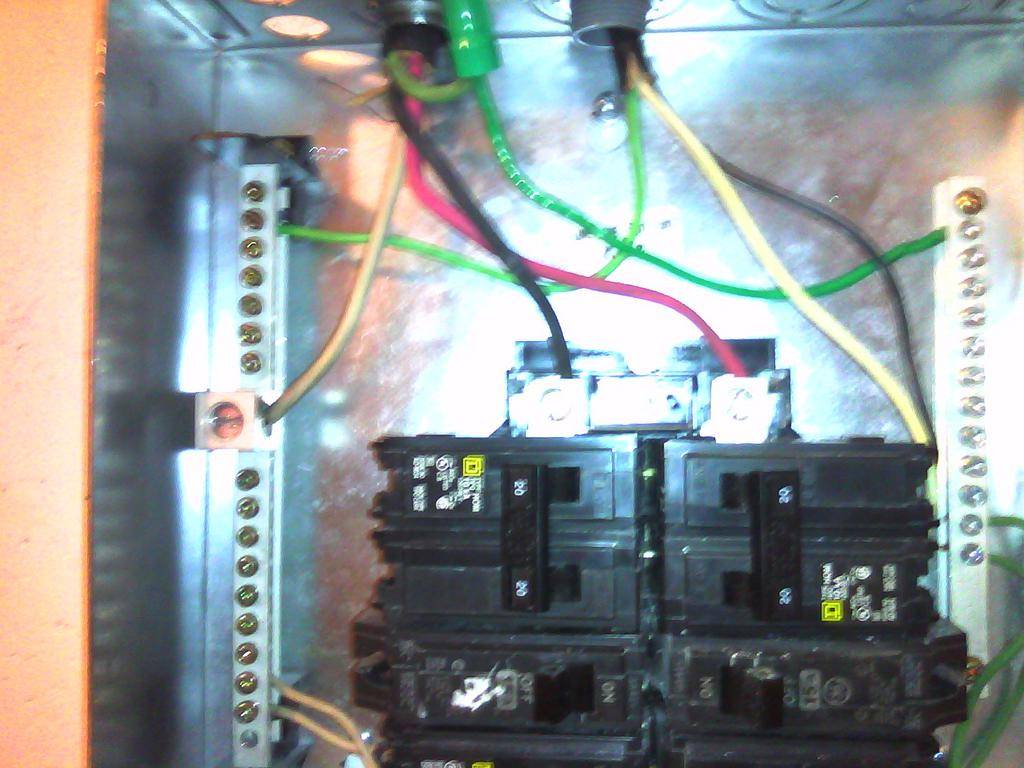

This is the Main panel with the new 60A breaker. Using 8/4 wire. Red, and Black to the breaker, white to the hot bar, and green to ground

Then to the sub panel. Black on left, Red on Right, White to the hot bar, and Green to the grounding bar I bought, and installed yesterday.

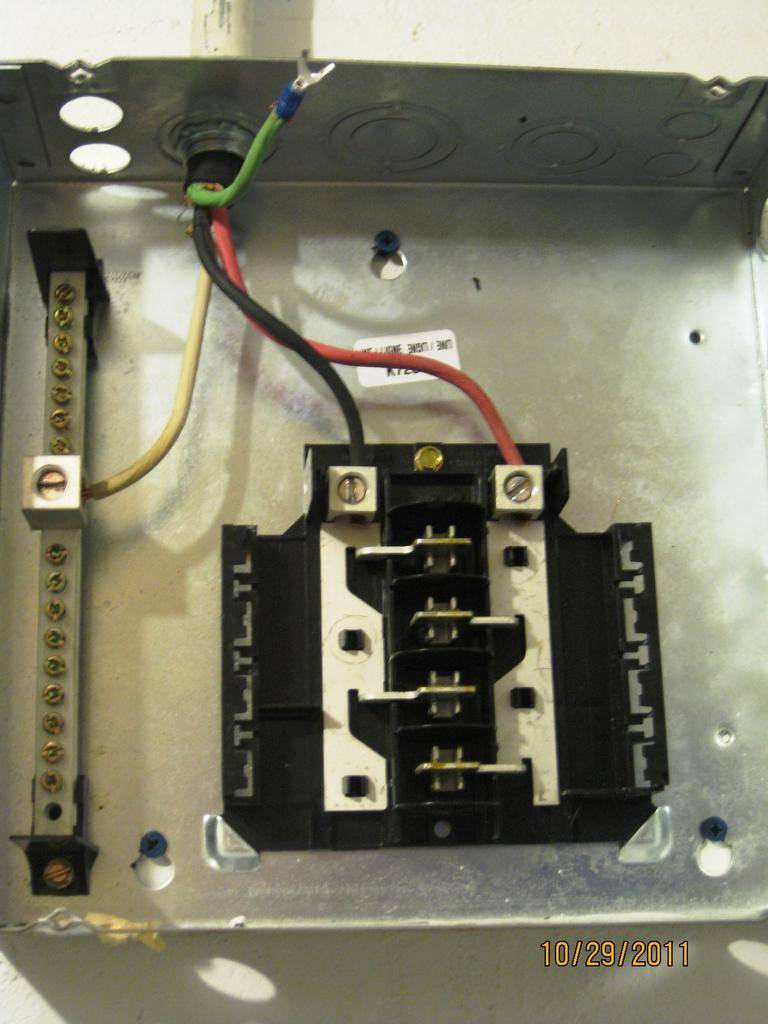

The Sub Panel with breakers installed, and switching to 14/3 wire

For the 20A 240 breaker Black, and white to the breaker, and green ground to the hot bar. The two 120 20A breakers. Black to breaker, white to hot bar, and green to ground bar.

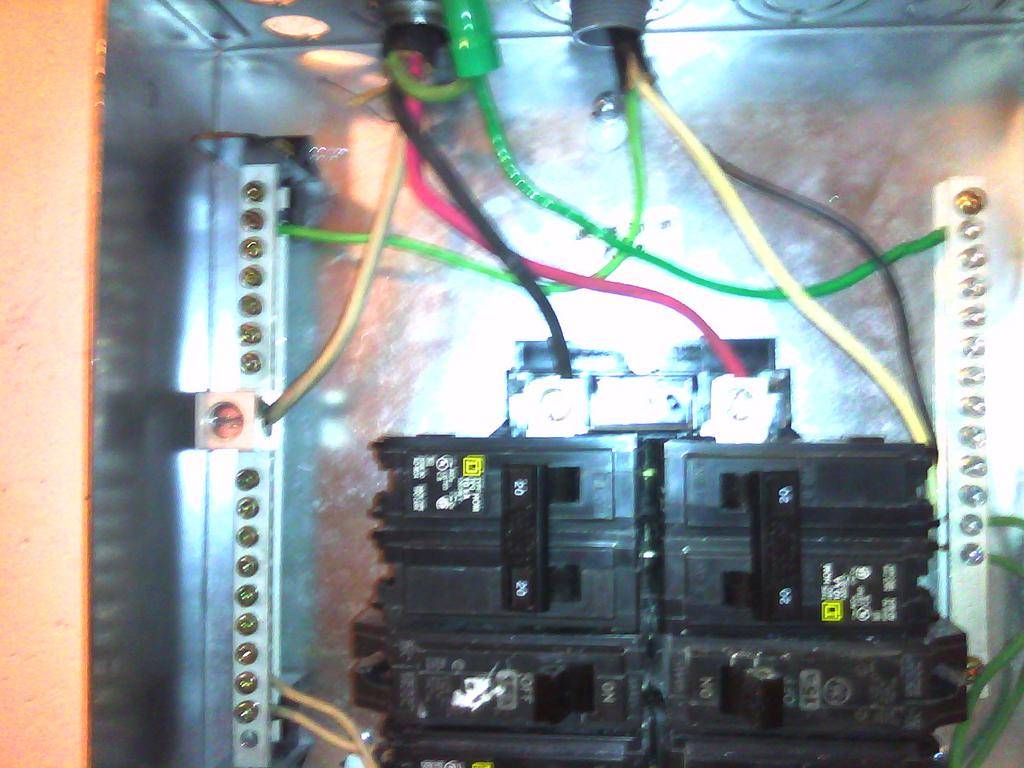

Then to the timer from the 240 20A breaker.

This is where I get a little confused. Should the white go to 'A', or to 3 Line? Right now I have it going to 3 Line.

Will be wiring the second timer today, and installing the jacks, and the ballasts.

Wanna make sure I've got this all wired correctly before flipping the switch at the main panel.

Sorry about the last few pics. They were taken with a camera phone cuz that's all I had available at the time

So. What do you think guys?

JG

Hey guys:

Just finishing up the wiring of the sub panel, and from there to the timers. Just want to be sure I've got this all right

This is the Main panel with the new 60A breaker. Using 8/4 wire. Red, and Black to the breaker, white to the hot bar, and green to ground

Then to the sub panel. Black on left, Red on Right, White to the hot bar, and Green to the grounding bar I bought, and installed yesterday.

The Sub Panel with breakers installed, and switching to 14/3 wire

For the 20A 240 breaker Black, and white to the breaker, and green ground to the hot bar. The two 120 20A breakers. Black to breaker, white to hot bar, and green to ground bar.

Then to the timer from the 240 20A breaker.

This is where I get a little confused. Should the white go to 'A', or to 3 Line? Right now I have it going to 3 Line.

Will be wiring the second timer today, and installing the jacks, and the ballasts.

Wanna make sure I've got this all wired correctly before flipping the switch at the main panel.

Sorry about the last few pics. They were taken with a camera phone cuz that's all I had available at the time

So. What do you think guys?

JG