lbezphil2005

Member

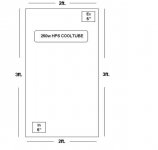

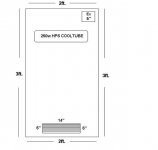

so series or parallel? lol, i have 2 Mechatronics 120x120x38mm High Speed AC Fans 106 cfm each max,my space is 31 inches tall,36 inches wide and 18 inches deep,cfl's totaling 249 watts(4-42's,and 3-27's) i wanna make a scrubber using kitty litter and carbon using my fans to pull the air from my cab thru the scrubber,trying to figure out if i should put the fans side by side or stacked

side by side, let one exhaust the heat from the lights the other can clean the air - plenty of cfms for that small of space