just thought I would make a quick post to help those that want to purchase a mini-split ac unit but fear the vacuuming stage or do not want to call someone out to perform this duty for you.

you need to order 2 parts to allow you to complete this step of the mini-split install. one is a vacuum pump and the other is a manifold (gauges) with hoses. both of these parts can be had for a total of less than $300. Some manifolds are sold separately from hoses so you can buy them individually if you can not find them sold together. i am including part numbers for the parts i have actually used with great success. this process is easy and will only take a half of an hour to complete.

pump - Robinair 5CFM Vacumaster Vacuum Pump 15500

manifold - Yellow Jacket 42004 Manifold with hoses

now the process will be outlined in your units instructions but to simplify...

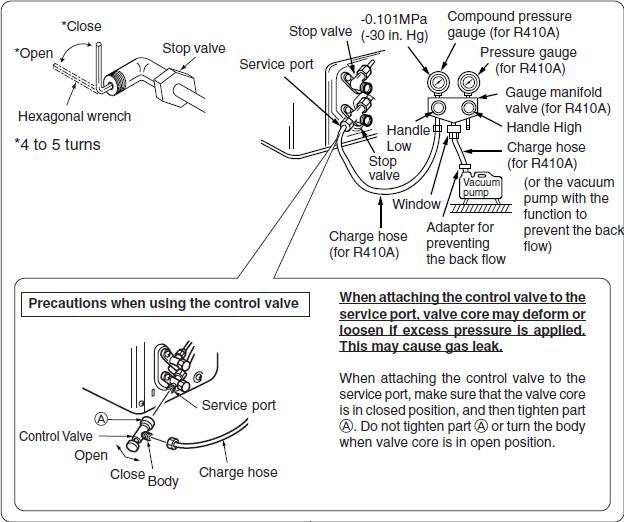

hook up the entire unit as your directions state. before powering on the unit you want to take the hose that is under the left gauge of the manifold and connect it to the service port of the unit you are installing. the hose from the center of the manifold will connect to the vacuum pump.

illustration

now you want the valves on the unit to remain closed. they are hidden under brass caps where you connected the line set to the outdoor part of the unit. the service port is located there as well.

with the line set installed and torqued to specifications and manifold connected to service port and pump, you can now vacuum the line set. make sure the valve on the manifold that corresponds to the left gauge is all the way open. you will see the needle stay at "0". now switch on the pump and let it run for about 15 minutes. you will see the needle drop into the negative. you want the needle to move all the way down to "-30".

you can see "-30" at the bottom left side of the gauge.

after 15 minutes of vacuuming, close the valve on the manifold for the left gauge and switch off the pump. this is the "leak test" portion of the procedure. you want the needle to stay at "-30" or wherever it was close to that when you closed the valve. wait for 5-10 minutes and ensure the needle has not moved. this indicates there are no leaks in the line set (usually connections) between the indoor and outdoor portions of the unit. if the needle has not moved... you should be good to go. disconnect the manifold from the service port and open the valves on the outdoor unit as specified in the directions.

that's it! hope it helps a few of ya

you need to order 2 parts to allow you to complete this step of the mini-split install. one is a vacuum pump and the other is a manifold (gauges) with hoses. both of these parts can be had for a total of less than $300. Some manifolds are sold separately from hoses so you can buy them individually if you can not find them sold together. i am including part numbers for the parts i have actually used with great success. this process is easy and will only take a half of an hour to complete.

pump - Robinair 5CFM Vacumaster Vacuum Pump 15500

manifold - Yellow Jacket 42004 Manifold with hoses

now the process will be outlined in your units instructions but to simplify...

hook up the entire unit as your directions state. before powering on the unit you want to take the hose that is under the left gauge of the manifold and connect it to the service port of the unit you are installing. the hose from the center of the manifold will connect to the vacuum pump.

illustration

now you want the valves on the unit to remain closed. they are hidden under brass caps where you connected the line set to the outdoor part of the unit. the service port is located there as well.

with the line set installed and torqued to specifications and manifold connected to service port and pump, you can now vacuum the line set. make sure the valve on the manifold that corresponds to the left gauge is all the way open. you will see the needle stay at "0". now switch on the pump and let it run for about 15 minutes. you will see the needle drop into the negative. you want the needle to move all the way down to "-30".

you can see "-30" at the bottom left side of the gauge.

after 15 minutes of vacuuming, close the valve on the manifold for the left gauge and switch off the pump. this is the "leak test" portion of the procedure. you want the needle to stay at "-30" or wherever it was close to that when you closed the valve. wait for 5-10 minutes and ensure the needle has not moved. this indicates there are no leaks in the line set (usually connections) between the indoor and outdoor portions of the unit. if the needle has not moved... you should be good to go. disconnect the manifold from the service port and open the valves on the outdoor unit as specified in the directions.

that's it! hope it helps a few of ya

Last edited: